Method for discoloring in process of refining coarse titanium tetrachloride from organic substances

A technology of crude titanium tetrachloride and refined titanium tetrachloride, which is applied in the direction of titanium tetrachloride and titanium halide, can solve problems such as unqualified chroma, achieve high production efficiency, simple production process, equipment addition and modification little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below, but it should not be understood that the scope of the subject matter of the present invention is limited to the following embodiments. Various modifications, substitutions and alterations are included within the scope of the present invention.

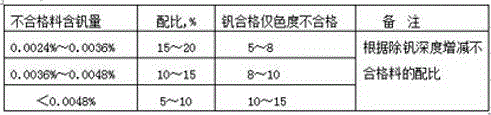

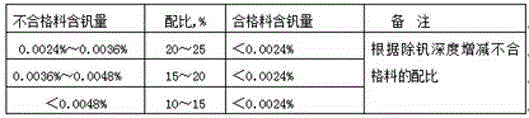

[0018] Organic matter vanadium removal refined titanium tetrachloride production process: Organic matter is fully mixed with crude titanium tetrachloride according to the ratio and the purpose of vanadium removal is achieved in the first-stage vanadium removal packed tower——the qualified titanium tetrachloride for vanadium removal passes through the float valve tower Remove low boiling point substances (silicon tetrachloride, etc.), qualified semi-finished titanium tetrachloride removes high boiling point substances (FeCl 3 etc.), chromaticity, to obtain qualified refined titanium tetrachloride products. In the refining production, the product quality requirements are:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com