A kind of treatment method of polyolefin catalyst containing titanium and organic matter waste acid water

A technology of polyolefin catalyst and treatment method, which is applied in the direction of special compound water treatment, oxidized water/sewage treatment, chemical instruments and methods, etc. It can solve problems such as rare reports, and achieve the effect of reducing risks and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

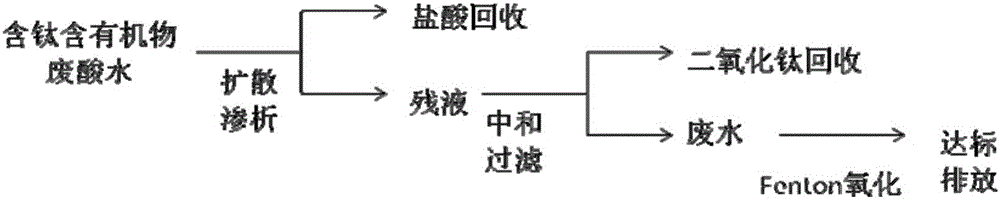

[0045] The polypropylene catalyst used in this example contains titanium-containing waste acid water containing organic matter from the hydrolysis of the hydrolysis tank in the preparation process of the polypropylene industrial Ziegler-Natta catalyst, wherein the mass concentration of hydrochloric acid is 26%, and the mass concentration of titanium is 13% %, TOC is 3000mg / L.

[0046] The experimental procedure of this embodiment:

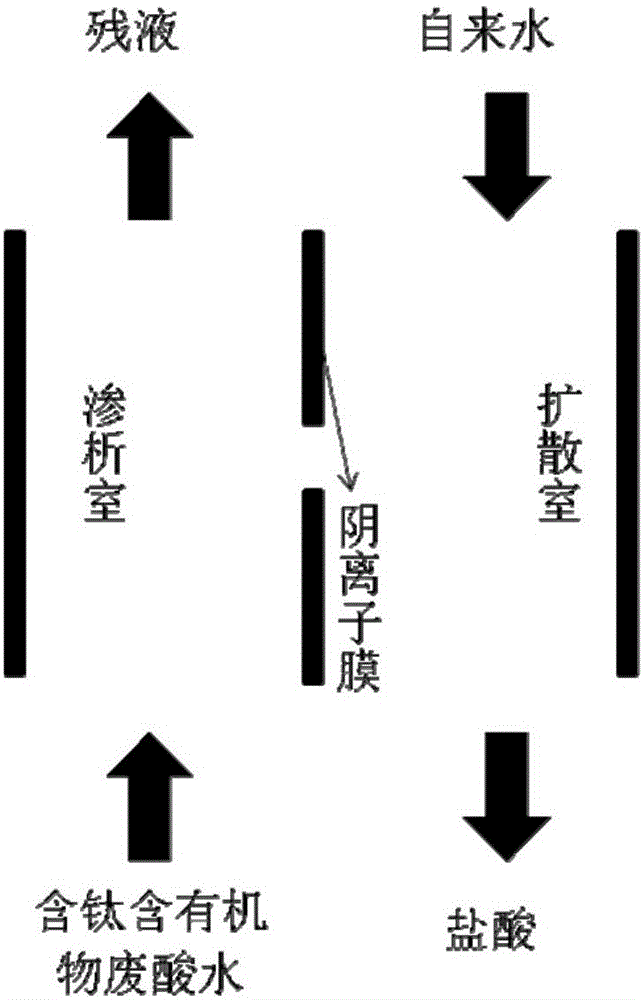

[0047] 1) Add the waste acid water containing polyolefin catalyst containing titanium and organic matter to the dialysis chamber of the diffusion dialyzer, and tap water is added to the diffusion chamber of the diffusion dialyzer, wherein the added polyolefin catalyst containing waste acid water containing titanium and organic matter and tap water The mass ratio of the dialysis chamber is 1:1, the anion membrane is separated between the dialysis chamber and the diffusion chamber. Reclaim, the mass ratio of the hydrochloric acid that reclaims and t...

Embodiment 2

[0051] The polypropylene catalyst used in this example contains titanium-containing waste acid water containing organic matter from the hydrolysis of the hydrolysis tank in the preparation process of the polypropylene industrial Ziegler-Natta catalyst, wherein the mass concentration of hydrochloric acid is 20%, and the mass concentration of titanium is 10% %, TOC is 1000mg / L.

[0052] The experimental procedure of this embodiment:

[0053] 1) Add the waste acid water containing polyolefin catalyst containing titanium and organic matter to the dialysis chamber of the diffusion dialyzer, and tap water is added to the diffusion chamber of the diffusion dialyzer, wherein the added polyolefin catalyst containing waste acid water containing titanium and organic matter and tap water The mass ratio of the dialysis chamber is 1:1.5, and the anion membrane is separated between the dialysis chamber and the diffusion chamber. Carry out recovery, the mass ratio of the hydrochloric acid th...

Embodiment 3

[0057] The polypropylene catalyst used in this example contains titanium-containing waste acid water containing organic matter from the hydrolysis of the hydrolysis tank in the preparation process of the polypropylene industrial Ziegler-Natta catalyst, wherein the mass concentration of hydrochloric acid is 23%, and the mass concentration of titanium is 12% %, TOC is 2000mg / L.

[0058] The experimental procedure of this embodiment:

[0059] 1) Add the waste acid water containing polyolefin catalyst containing titanium and organic matter to the dialysis chamber of the diffusion dialyzer, and tap water is added to the diffusion chamber of the diffusion dialyzer, wherein the added polyolefin catalyst containing waste acid water containing titanium and organic matter and tap water The mass ratio of the dialysis chamber is 1:1.2, the anion membrane is separated between the dialysis chamber and the diffusion chamber, and the two flow in reverse. After 3 hours of diffusion dialysis, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com