Polyester composite elastic fiber

A composite elastic fiber and polyester technology, which is applied in the direction of conjugated synthetic polymer rayon, textiles, papermaking, yarn, etc., can solve the problems of difficult adjustment, tight elasticity, hard fiber feel, etc., and achieve cost saving and elasticity Sufficient, flexible range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

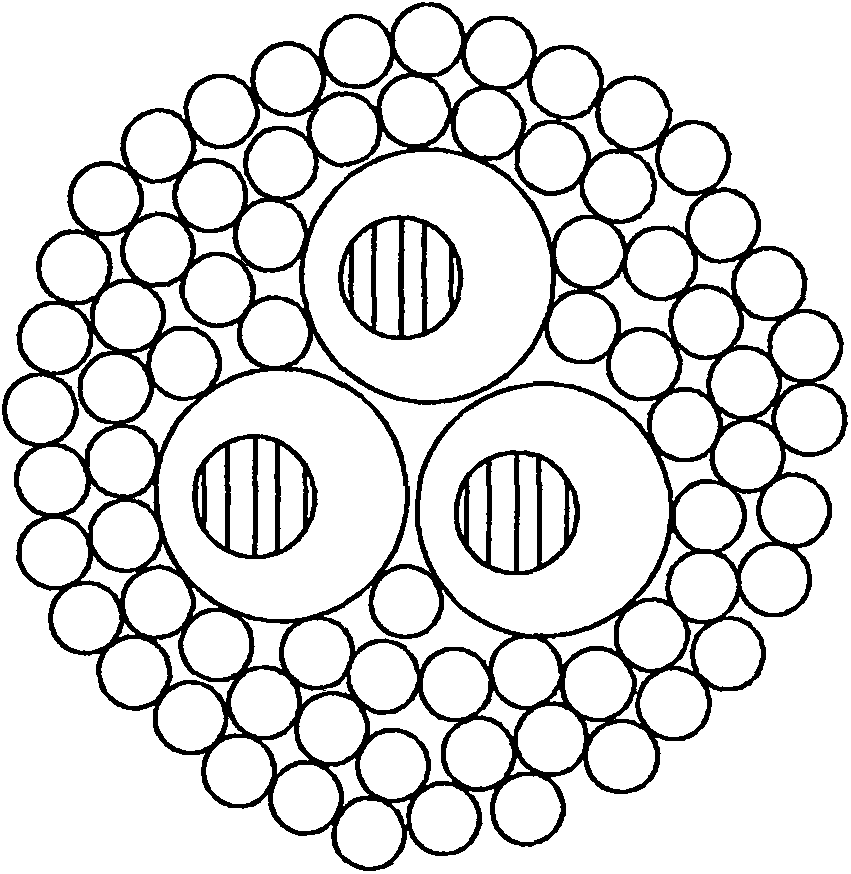

Image

Examples

Embodiment 1

[0018] ECDP with an intrinsic viscosity of 0.58dL / g is used as component A, and PTT with an intrinsic viscosity of 1.02dL / g is used as component B, with a weight ratio of A:B=83:17, respectively supplied to the two screws of the composite spinning equipment The extruder and the metering pump are respectively metered and fed into the two-component composite spinning box. After being extruded through a specific spinneret, the ring air is cooled and oiled. The spinning temperature is 285°C, and the tow is wound (speed 1500m / min) after drafting and setting, first-stage drafting (drawing temperature 150°C, drafting ratio 1.2 times), secondary drafting (drawing temperature 190°C, drafting ratio 4 times), drafting speed 400m / min, Filaments are produced. The filaments are dry heat treated at 140°C to obtain polyester composite elastic fibers with excellent properties.

[0019] The inner side of the fiber is wrapped with 7 eccentric core-sheath type ECDP / PTT composite coarse denier y...

Embodiment 2

[0021] PET with an intrinsic viscosity of 0.70dL / g is used as component A, and PBT with an intrinsic viscosity of 1.05dL / g is used as component B, with a weight ratio of A:B=70:30, respectively supplied to the two screws of the composite spinning equipment The extruder and the metering pump are respectively metered and fed into the two-component composite spinning box. After being extruded through a specific spinneret, the ring air is cooled and oiled. The spinning temperature is 290°C, and the tow is wound (speed 2000m / min) after drafting and setting, primary drafting (drawing temperature 140°C, drafting multiple 1.8 times), secondary drafting (drawing temperature 160°C, drafting multiple 3 times), drafting speed 600m / min, Filaments are produced. The filaments are dry heat treated at 150°C to obtain polyester composite elastic fibers with excellent properties.

[0022] The inner side of the fiber is wrapped with 10 side-by-side PET / PBT composite coarse denier yarns, with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com