Medium and low speed maglev traffic engineering low line curve rail bearing beam structure

A technology for traffic engineering and low-lying lines, applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of difficulty in guaranteeing, reducing the stability of rail-bearing beams, and sinking grooves of rail-bearing beams, so as to achieve convenient construction and avoid stability. Sexual problems, the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

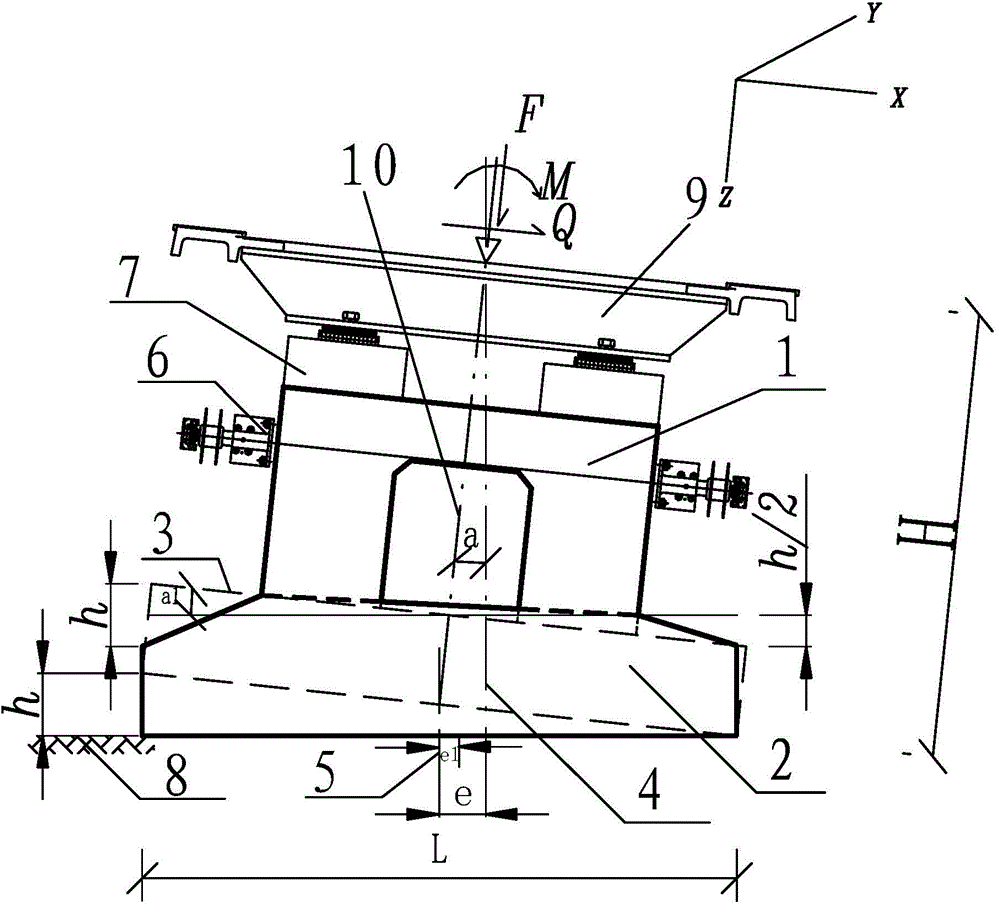

[0021] Such as figure 1 The curved rail beam structure of the low-set line in the medium-low speed maglev traffic project shown includes a rail beam body 1, a sleeper pedestal 7 fixed on the top of the rail beam body 1, and a rail row 9 fixed on the top of the sleeper pedestal 7 , the reinforced concrete bottom plate 2 fixed on the horizontal subgrade surface 8, the guide rails 6 arranged on both sides of the rail bearing beam body 1, the top surface of the reinforced concrete bottom plate 2 is arranged obliquely relative to the horizontal plane, and the top surface of the reinforced concrete bottom plate 2 The angle between the horizontal plane and the horizontal plane is α1, the bottom surface of the rail-bearing beam body 1 is fixedly connected to the top surface of the reinforced concrete floor 2, and the axes of the rail-bearing beam body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com