A raking device that can heat old asphalt concrete at the same time

A technology for concrete and old asphalt, which is applied in the field of asphalt pavement heating and raking equipment, which can solve the problems of increasing the resistance of raking equipment, damage to equipment, easy damage to the original gradation of asphalt mixture, and fire and coking on the surface of asphalt roads, so as to facilitate raking loosening process, facilitate subsequent use, and protect the effect of pavement structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the traditional raking process of asphalt pavement, it is necessary to preheat the pavement and then rake it, which requires two processes. However, when the pavement is preheated, in order to fully soften the asphalt pavement to facilitate raking, the method of heating the same place for a long time or increasing the heating temperature is often used: the common defect of these two methods is that it consumes more energy. At the same time, the effect is not ideal. The reason is that under the action of a long time or high temperature, the asphalt pavement is prone to coking, which will affect the raking process instead; in addition, raking after preheating requires a relatively close cooperation, but in practice Effective cooperation cannot be achieved in the operation process, which makes the road surface harden after softening, which brings a lot of troubles to the actual operation process.

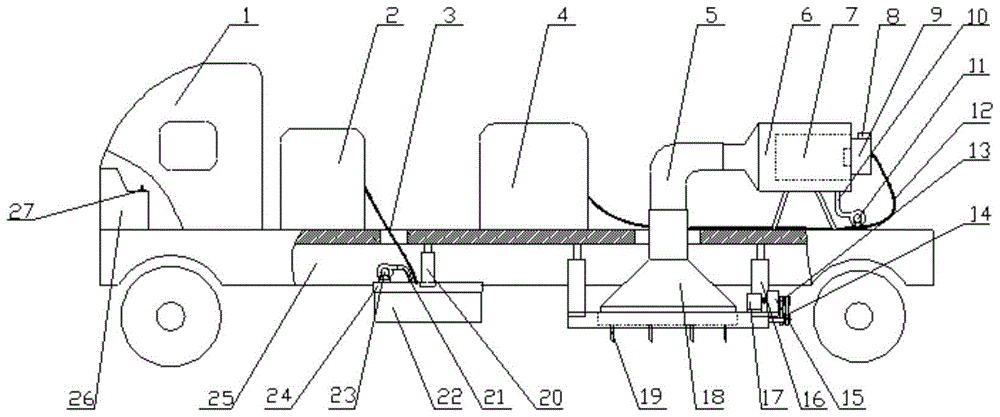

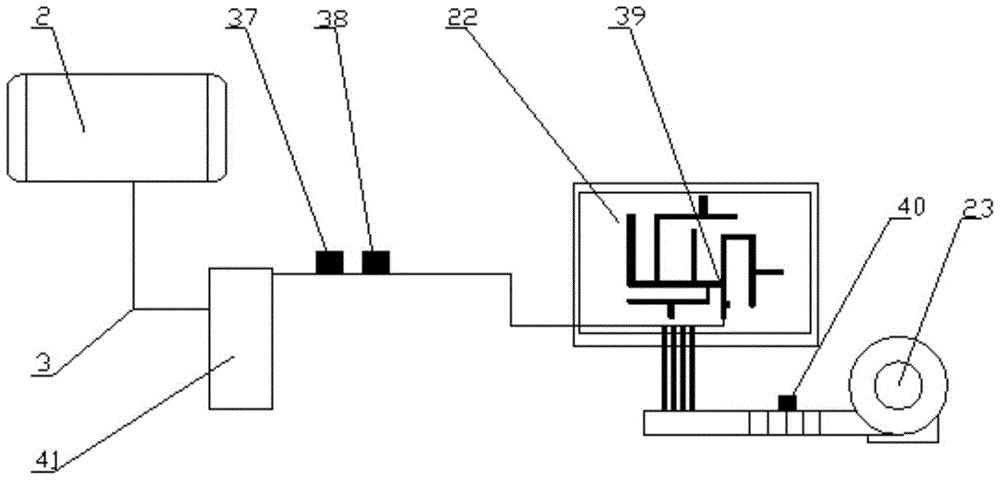

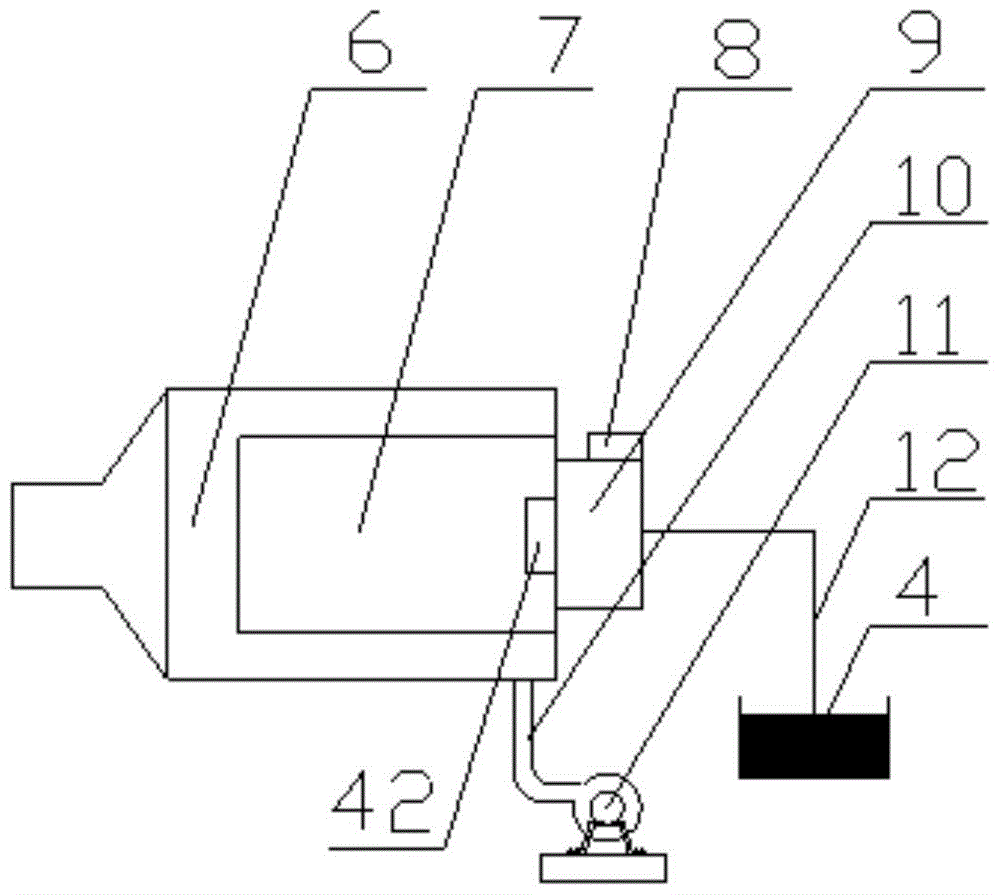

[0031] In view of these problems, the present invention proposes a rakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com