Paver with adjustable paving width

A paver and width technology, applied in the directions of roads, road repair, roads, etc., can solve the problems of small adjustment amount, low compactness, and inability to adjust the length, so as to reduce bending deformation and torsional deformation, and achieve smooth paving. High degree of economical and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

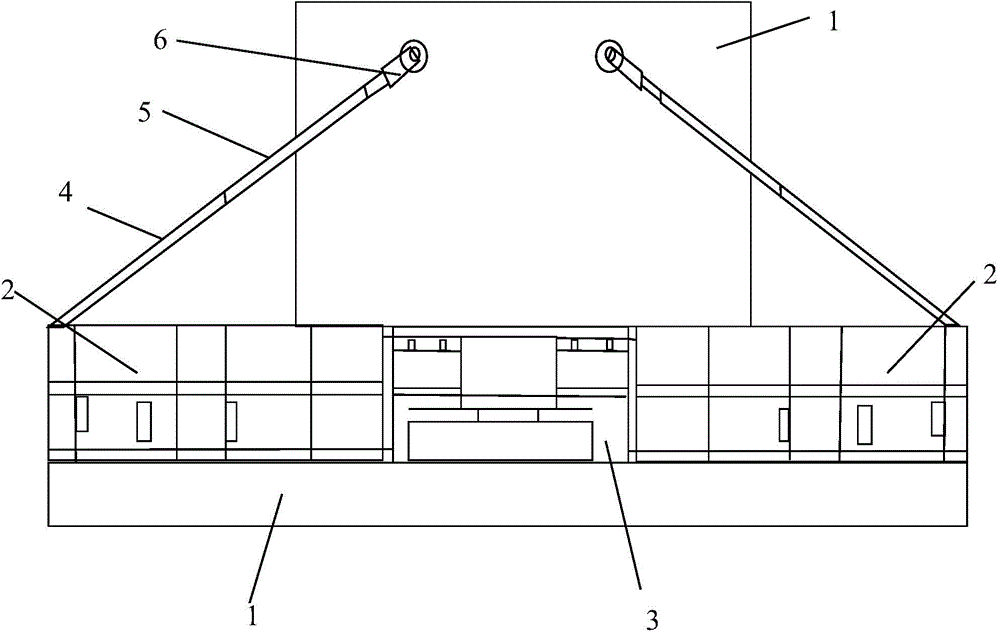

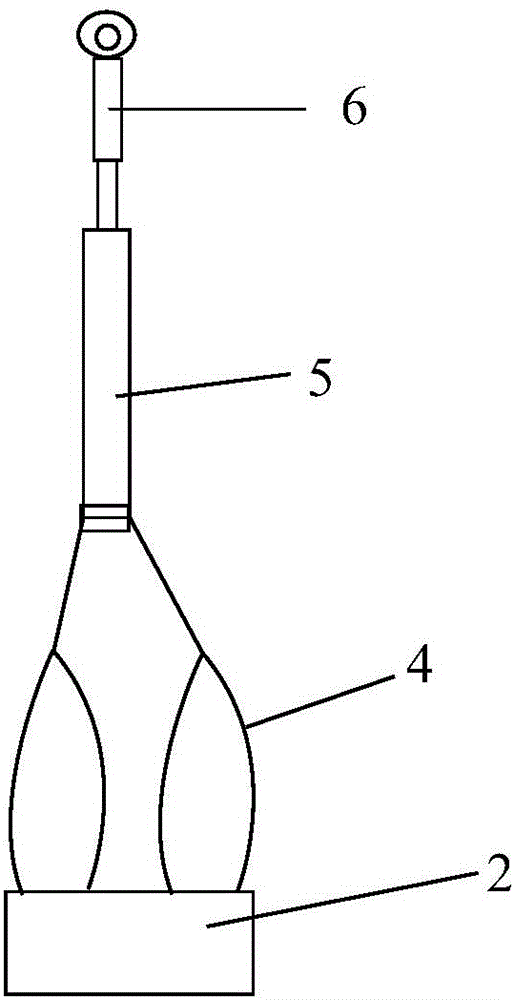

[0016] A paver with adjustable paving width, comprising a main machine 1, a screed main body 3, a hydraulic telescopic screed 2, a hydraulic telescopic screed 2, and a screed main body 3 respectively connected to the main machine 1, two hydraulic telescopic The screed 2 is installed on the left and right sides of the main body 3 of the screed, and the left and right sides of the host 1 are respectively provided with traction arms. The host 1 is connected to the traction arm through a connecting device. One end is hinged on the support arm, and the other end is connected to the traction arm. A locking mechanism is provided next to the tensioning cylinder. The traction arm is connected to the hydraulic telescopic screed 2 through a hinge shaft. The screed main body 3 along the two traction arms The central line is symmetrically arranged. The traction arm includes a main traction arm 5 and two rear traction arms 4. The main traction arm 5 is connected to the two rear traction arms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com