Floating object conveying system in front of trash rack for power plant water inlet

A conveying system and water inlet technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve the problems of high investment, low efficiency, discontinuity, etc., and achieve the effect of less maintenance personnel, high efficiency, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the embodiments should not be construed as limiting the present invention, but only as examples, and the advantages of the present invention will become clearer and easier to understand.

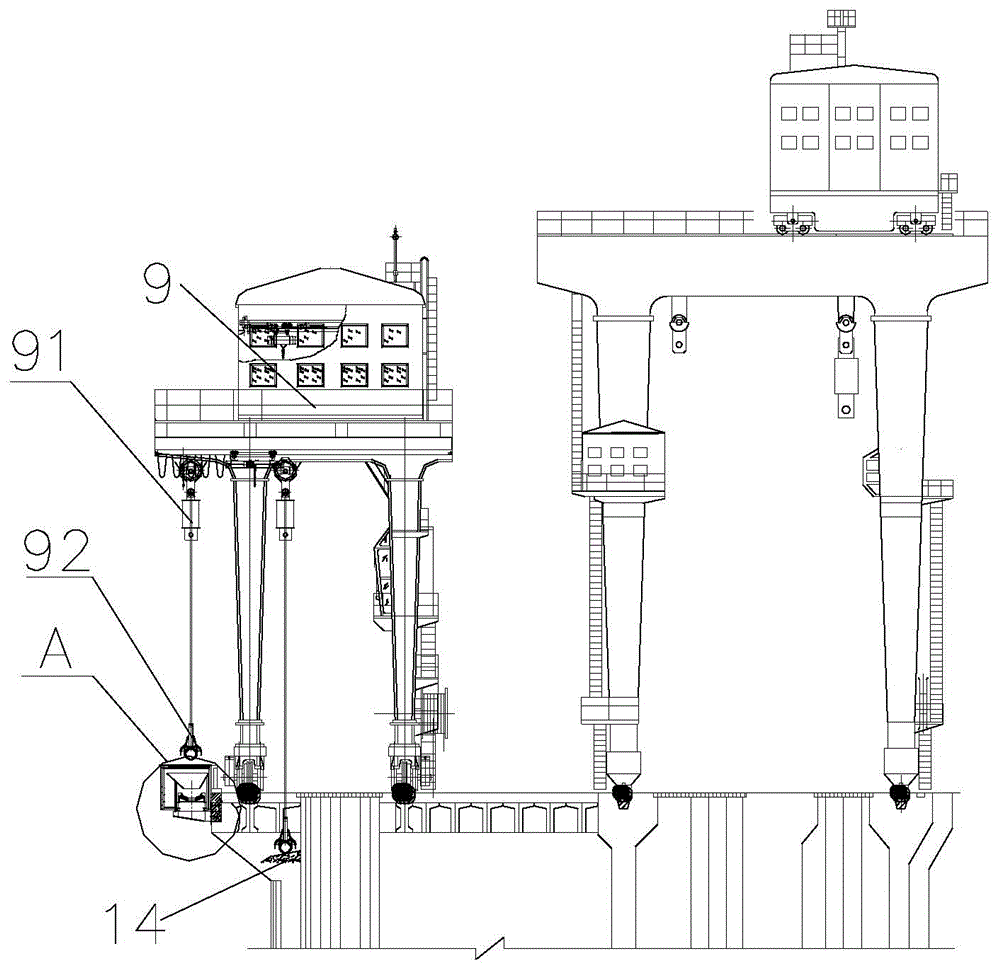

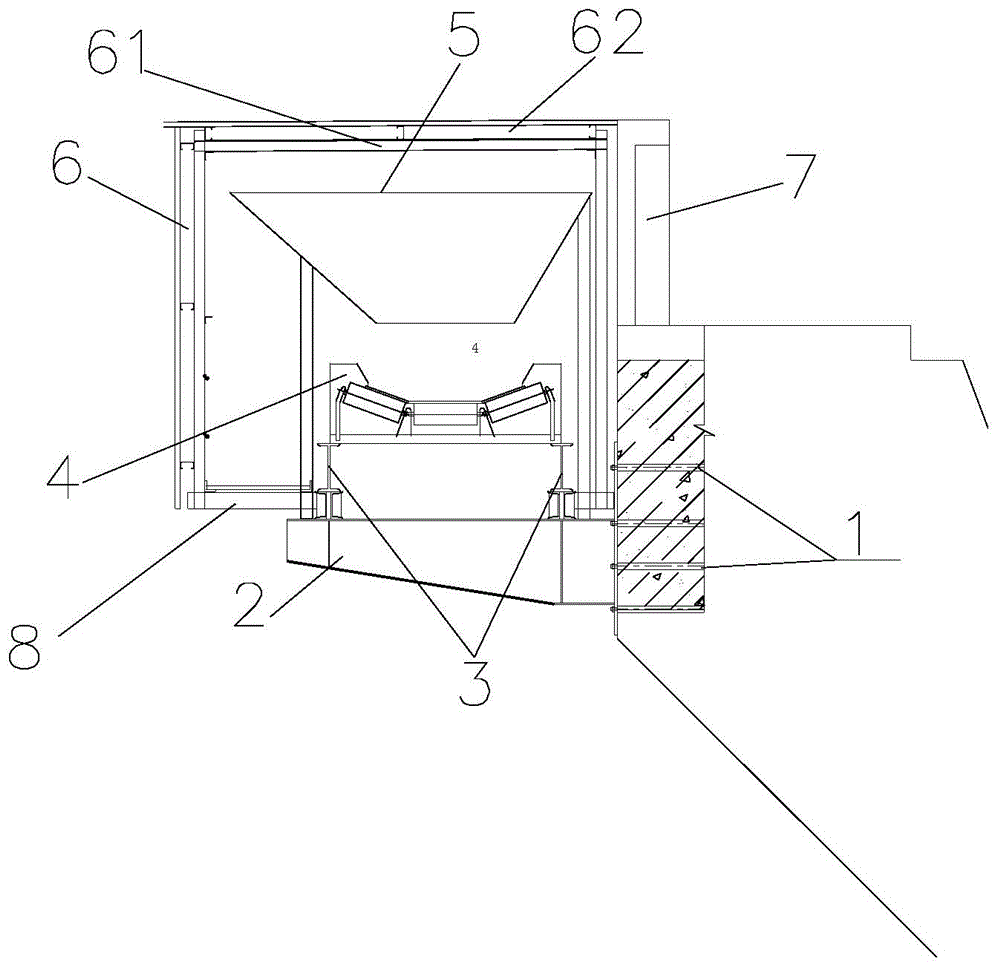

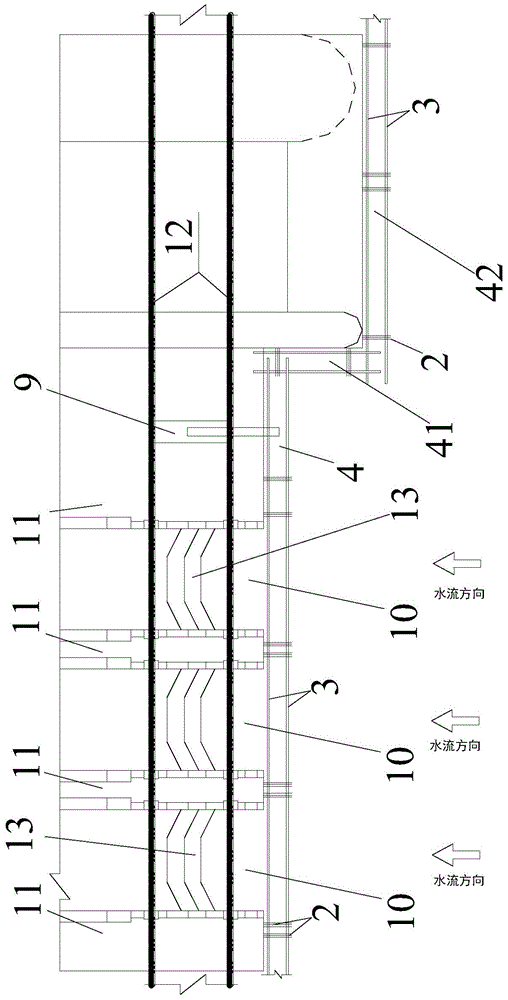

[0021] The floating debris conveying system in front of the trash rack of the water inlet of the power station is a floating debris treatment system installed on the dam body of the hydropower station, including the intercepting and grabbing part and the conveying part;

[0022] The intercepting and grasping part includes: several gate piers 11 on the upstream side of the dam body of the hydropower station; gate slot groups 13 are arranged between several gate piers 11; water inlet holes 10 are arranged in the upstream direction of the gate slot groups 13; The downstream direction is usually the door slot of the cleaning machine, the door slot of the trash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com