Quick presressed anchor rod structure and construction method

A construction method and prestressing technology, which is applied in the direction of basic structure engineering, building, sheet pile wall, etc., can solve the problems of reducing construction time and long waiting time, and achieve the effect of reducing construction period, reasonable structural design and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

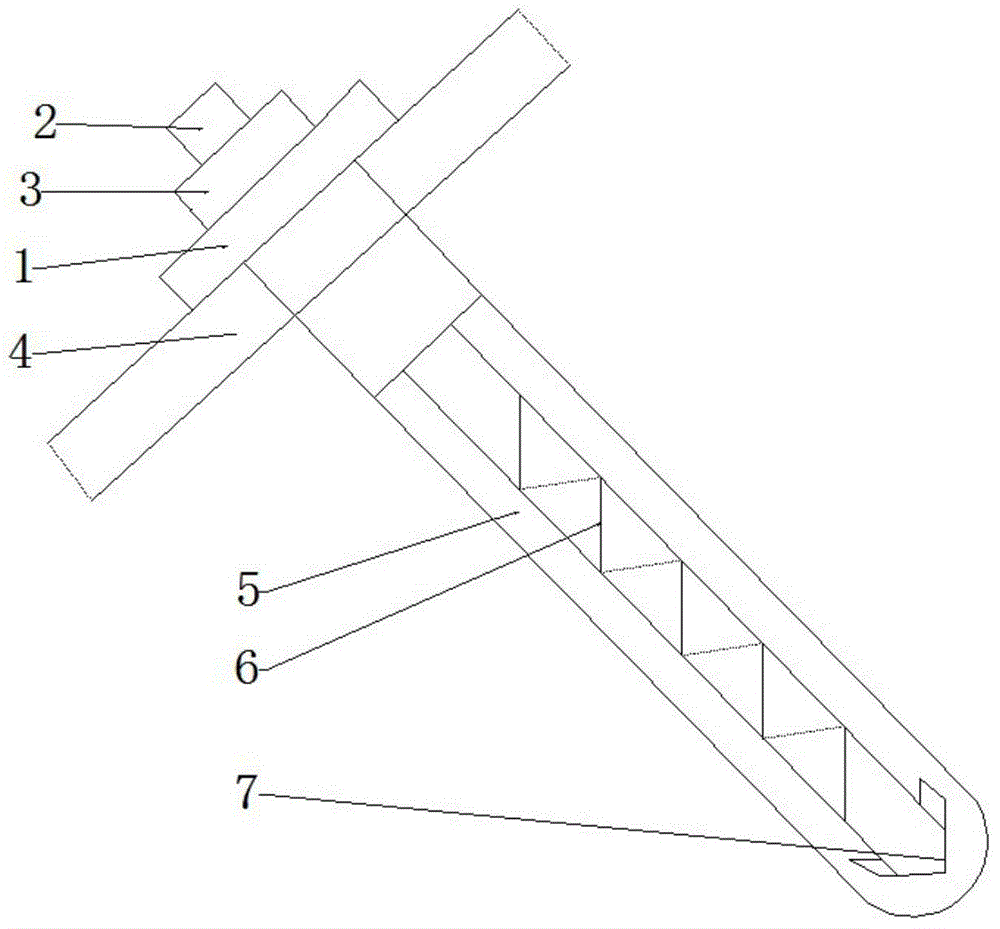

[0013] The rapid prestressed anchor rod structure and construction method of the present invention include: a gasket 1, an anchor rod 2, a nut 3, a fixed wall 4, an expansion groove 5, a rotating steel wire 6, and an anchor head barb 7.

[0014] The working principle of the present invention is as follows: the present invention provides a pre-embedded space for the anchor rod 2 through the expansion groove 5, and there is a rotating steel wire 6 around the anchor rod 2, which produces a very large resistance when it is axially inward. The low end of the expansion groove 5 of 2 has anchor head barb 7 and can realize a kind of maximum resistance at terminal.

[0015] The construction method is as follows: Drill holes with an electric drill to realize the excavation of the expansion groove 5, install the anchor rod 2 into the expansion groove 5 acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com