Long nozzle alloy bit used for oilfield drilling

An oilfield drilling and alloy drill bit technology, applied in construction and other directions, can solve the problems of poor hydraulic energy distribution in the bottom hole flow field, high erosion of the alloy drill bit, poor rock clearing effect, etc., and achieves enhanced hydraulic rock breaking and rock clearing effect, Improve the effect of hydraulic energy and hydraulic rock breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further explained below in conjunction with the drawings:

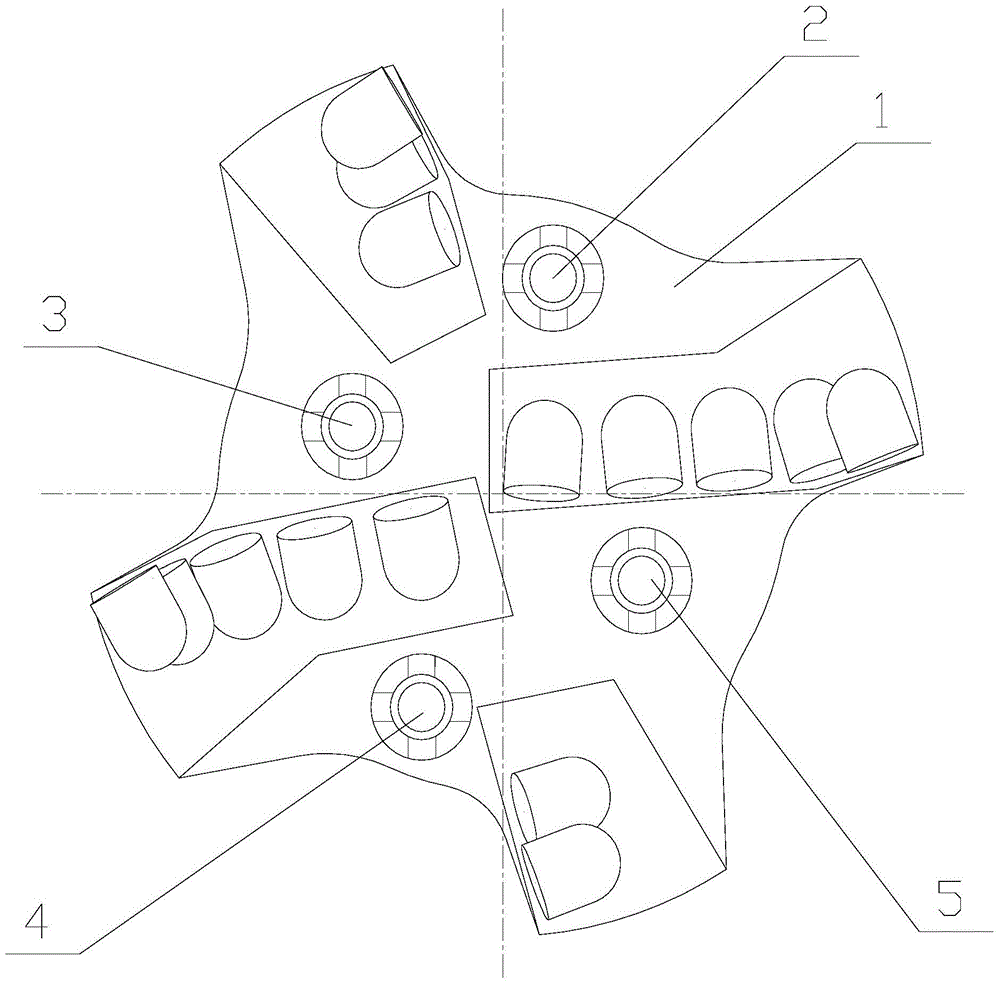

[0009] As shown in the drawings, the long nozzle alloy drill bit for oil field drilling includes a main body 1, a nozzle A 2, a nozzle B 3, a nozzle C 4, and a nozzle D 5. A nozzle 2, B nozzle 3, C nozzle 4 and D nozzle 5 are on the main body 1, A nozzle 2 is on the main body 1 in the Ⅰ quadrant, B nozzle 3 is on the main body 1 in the Ⅱ quadrant, and C nozzle 4 is on the main body 1 Ⅲ In the quadrant, the D nozzle 5 is in the IV quadrant above the main body 1, the A nozzle 2 and the C nozzle 4 are 55 mm higher than the main body 1, and the B nozzle 3 and the D nozzle 5 are 35 mm higher than the main body 1.

[0010] The long-nozzle alloy drill bit for oilfield drilling uses jet dynamics to optimize the hydraulic system and jet generation device of the drill bit without increasing the power of the ground mud pump, shortening the distance from the nozzle outlet on the drill bit to the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com