Combined aluminum alloy double-wall drill pipe unit

A double-wall drill pipe and aluminum alloy technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of handling and unloading of double-wall drill pipes, designing complex centering structures, increasing processing difficulties, etc. Achieve the effect of light weight, convenient handling and reasonable load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

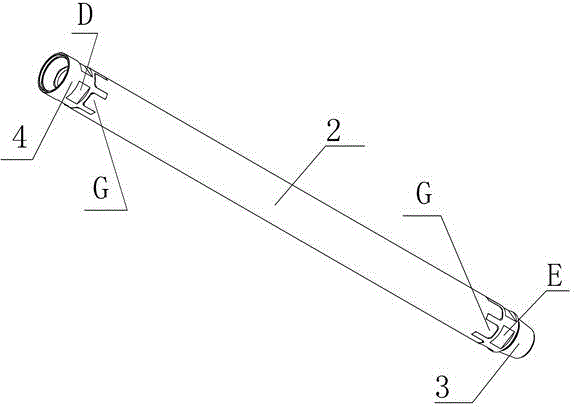

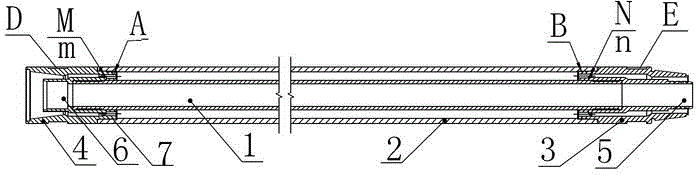

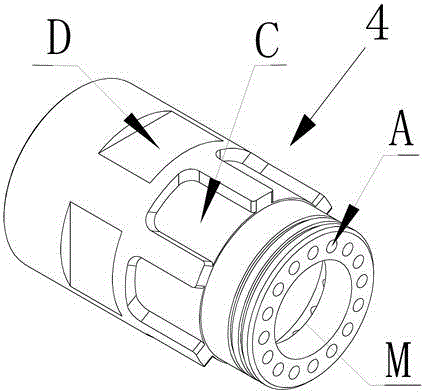

[0028] Such as figure 1 with figure 2 As shown, the present invention is composed of double-wall drill pipe inner pipe 1, double-wall drill pipe outer pipe 2, outer pipe upper joint 4, outer pipe lower joint 3, double-wall drill pipe inner pipe 2, inner pipe upper joint 6, inner The lower pipe joint 5 and the sealing ring 7 are formed. The two ends of the double-wall drill pipe outer pipe 2 are respectively connected with the outer pipe upper joint 4 and the outer pipe lower joint 3 through clamping grooves; the double-wall drill pipe outer pipe 2 and the outer pipe The upper joint 4 and the lower joint 3 of the outer tube are matched with a cylindrical surface provided with a sealing ring 7; the inner double-wall drill pipe 1 is located in the outer double-wall drill pipe 2, and both ends of the inner double-wall drill pipe 1 are threaded and connected to each other. The upper joint 6 of the inner pipe is connected with the lower joint 5 of the inner pipe; the upper joint end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com