Caisson type underwater gas-liquid separator

A gas-liquid separator and caisson-type technology, which is applied in the fields of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of manufacturing cost, high installation cost, bulky separator, etc., so as to reduce manufacturing difficulty, The effect of reducing difficulty and controlling liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

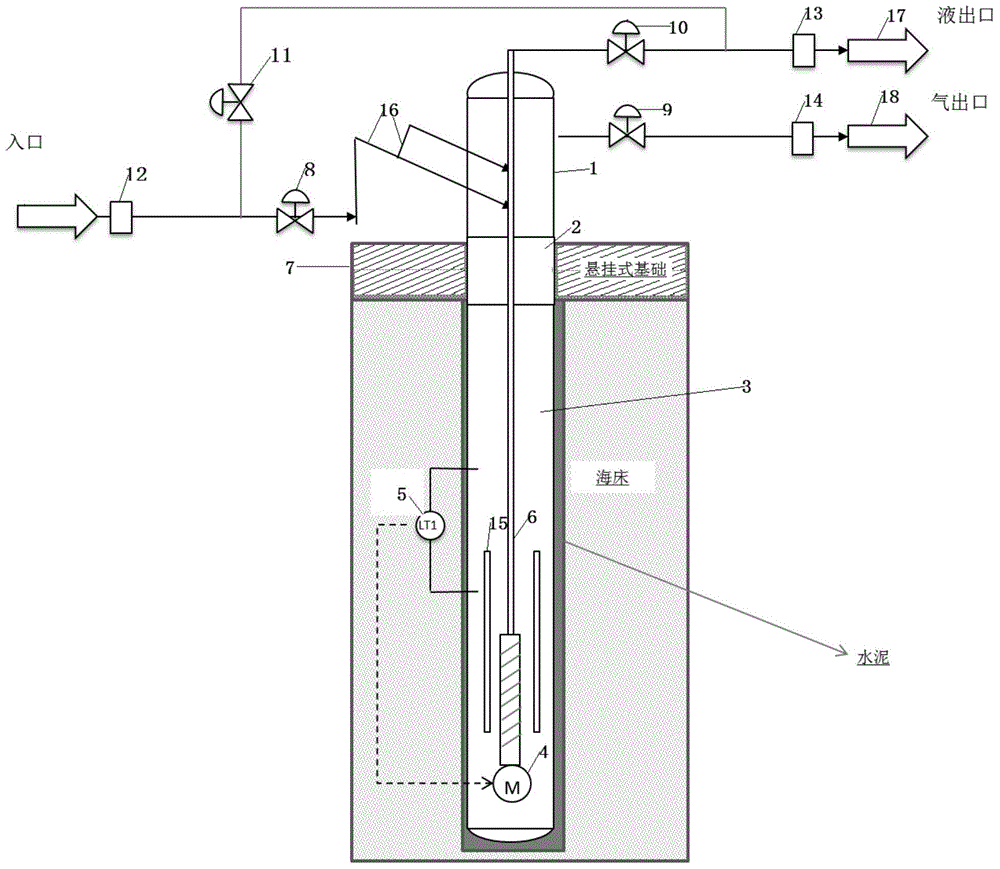

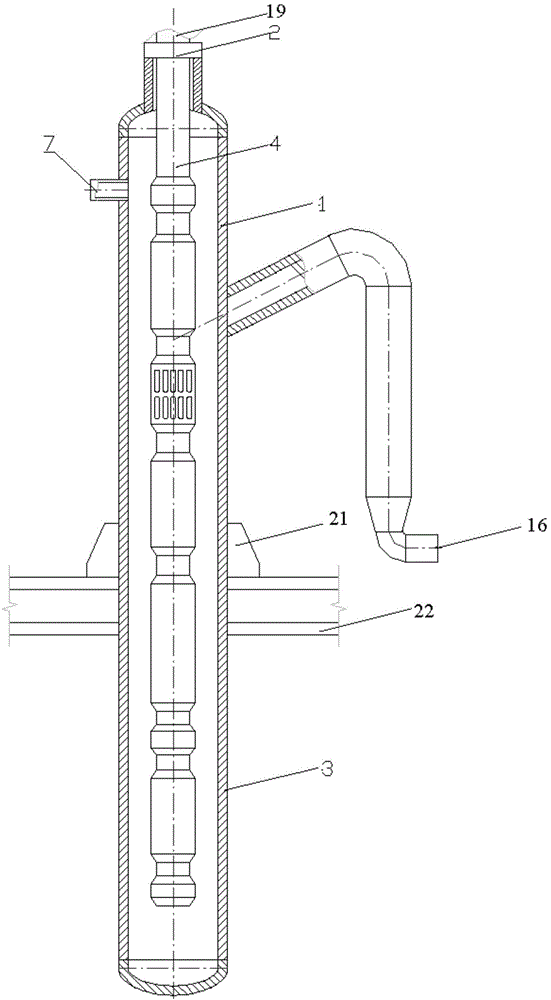

[0022] Such as figure 1 shown and figure 2 As shown, the caisson type underwater gas-liquid separator provided by the present invention comprises a gas-liquid cyclone separator 1 and a caisson type slug flow catcher 3, wherein the gas-liquid cyclone separator 1 and the caisson type slug flow catcher The device 3 communicates with a vertical underwater connector 2, and is fixed on a suspended installation base 7, and is fixed on a fixed base 22 through an installation bracket 21. The gas-liquid cyclone separator 1 communicates with two feeding pipelines 16, and an inlet shut-off valve 8 is provided on the feeding pipeline. Both feeding pipelines are connected to the gas-liquid cyclone separator 1 in a The inclination angle is 60°, so that the gas-liquid two-phase can be separated at the inclined f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com