Hand-held milling and digging machine manufacturing method

A production method and hand-held technology, which are applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of dead corners in the contour of the tunnel face, narrow tunnel operation environment, and inability to form excavation angles, so as to reduce labor costs. Excavation volume, labor saving, easy implementation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

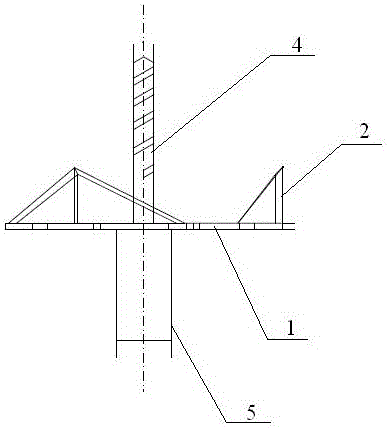

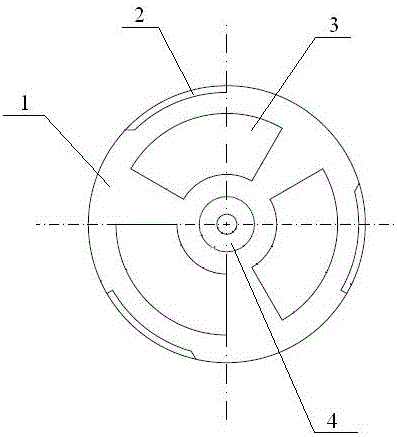

[0019] Such as figure 1 , figure 2 As shown, the manufacturing method of the hand-held milling and digging machine includes the following steps:

[0020] (1) After cutting an ordinary steel plate with a thickness of 8mm, respectively make a disc 1 with a diameter of 25cm~30cm and three milling cutter heads 2 with a right triangle cross section and a depth of 50mm~100mm;

[0021] (2) Open three excavation holes 3 at an angle of 120° on the disc 1;

[0022] (3) Three milling and digging cutter heads 2 are horizontally welded on the edge of the disc 1 at an angle of 120° by arc welding;

[0023] (4) Weld the 10cm¢18 twist drill bit on the 5cm¢20 seamless steel pipe 4, and the seamless steel pipe 4 is welded on the center of one side of the disc 1;

[0024] (5) A central connecting rod 5 is provided at the center of the other side of the disc 1, and the central connecting rod 5 is connected with an electric tool with a rotating speed of 500~540r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com