Full-section construction structure and construction method of large-section soft ground tunnel

A technology of weak stratum and construction method, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of high engineering cost, long time period for supporting ring formation, and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

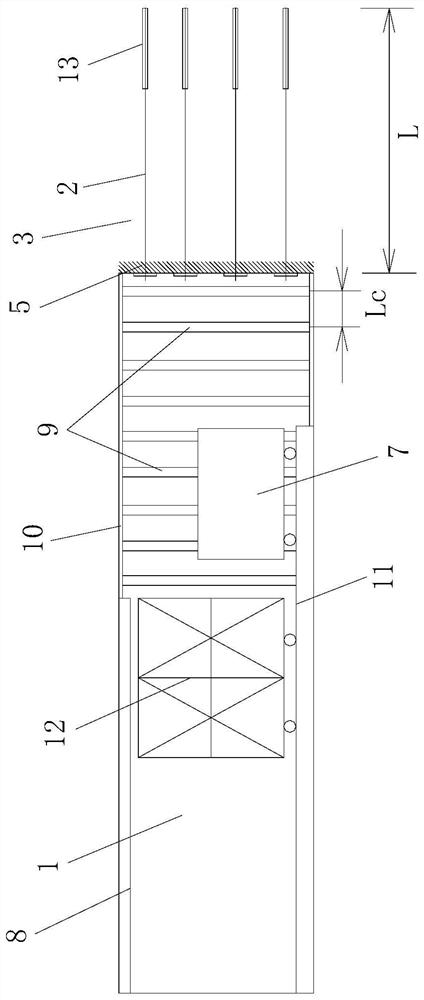

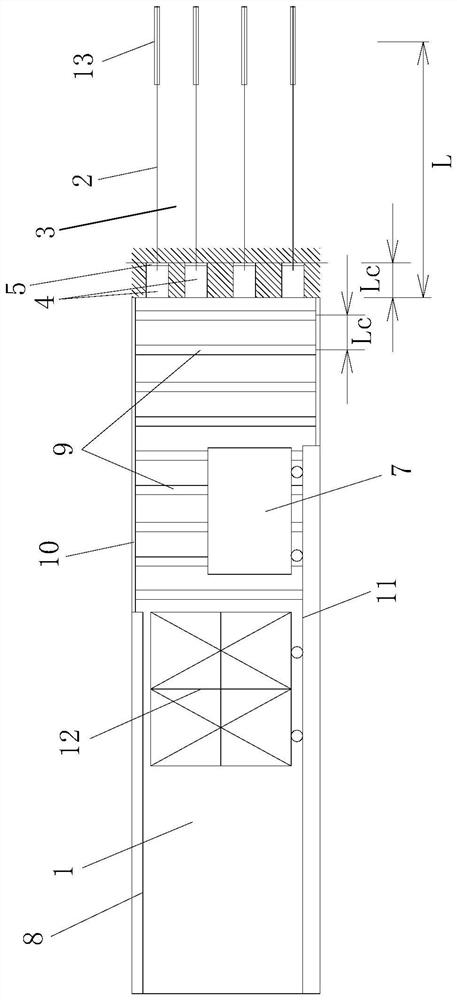

[0075] like figure 1 , figure 2 Full section one kind of weak stratum tunnel large section structure illustrated construction, the tunnel construction comprising a front working face 3 for rock excavation and tunnel excavation and anchoring of the anchoring system, the construction of the tunnel excavation cross-section is greater than 50m 2 Large cross section of soft rock tunnel or a large section loess tunnel; the tunnel excavation and anchoring system includes a plurality of front tunnel face excavation rock and tunnel excavation and anchoring of the anchoring means 3, a plurality of the tunnel opening structure digging and anchoring mechanisms are the same and which are located in front of the working face of the tunnel construction, the plurality of tunnel excavation and anchoring bodies and which are arranged parallel showed extending in the longitudinal direction of the tunnel construction tunnel laid;

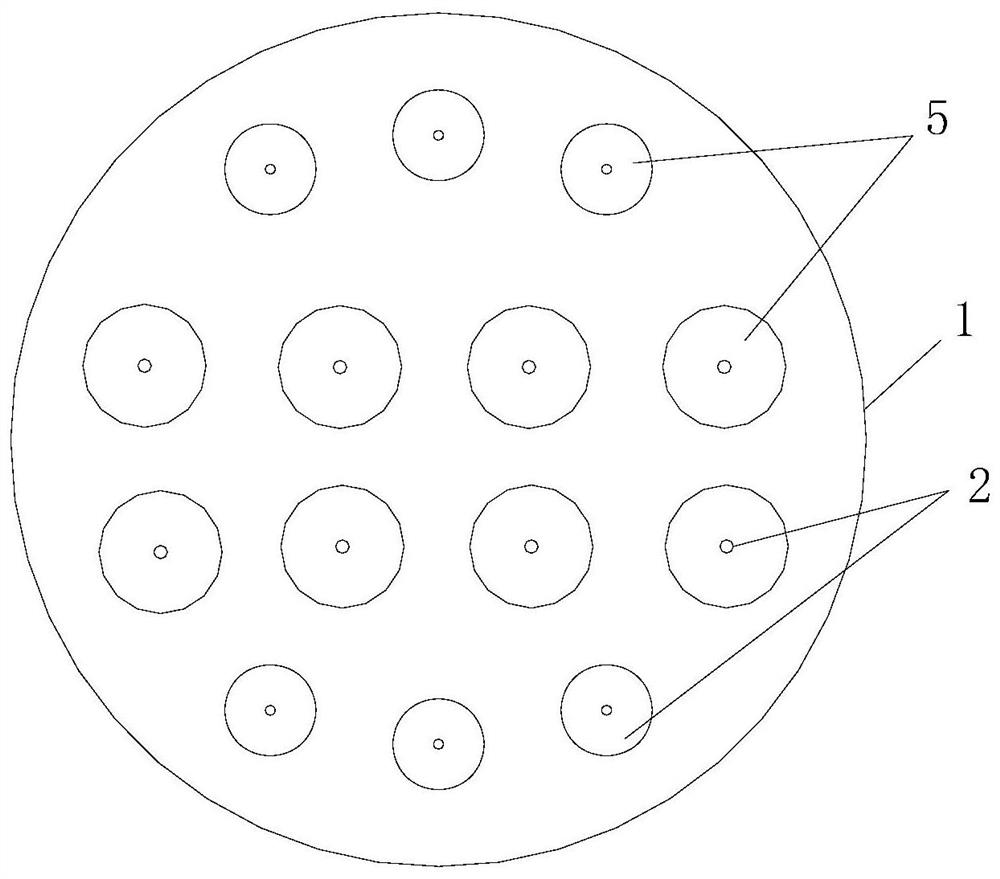

[0076] Combine image 3 Each of said tunnel excavation and anchoring m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com