DPF (diesel particulate filter) initiative regeneration system with combustor

An active regeneration and burner technology, applied in the direction of combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of difficult combustion process organization, poor combustion, secondary pollution, etc., to ensure controllability and realizability , Reduction of regeneration cost, high combustion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

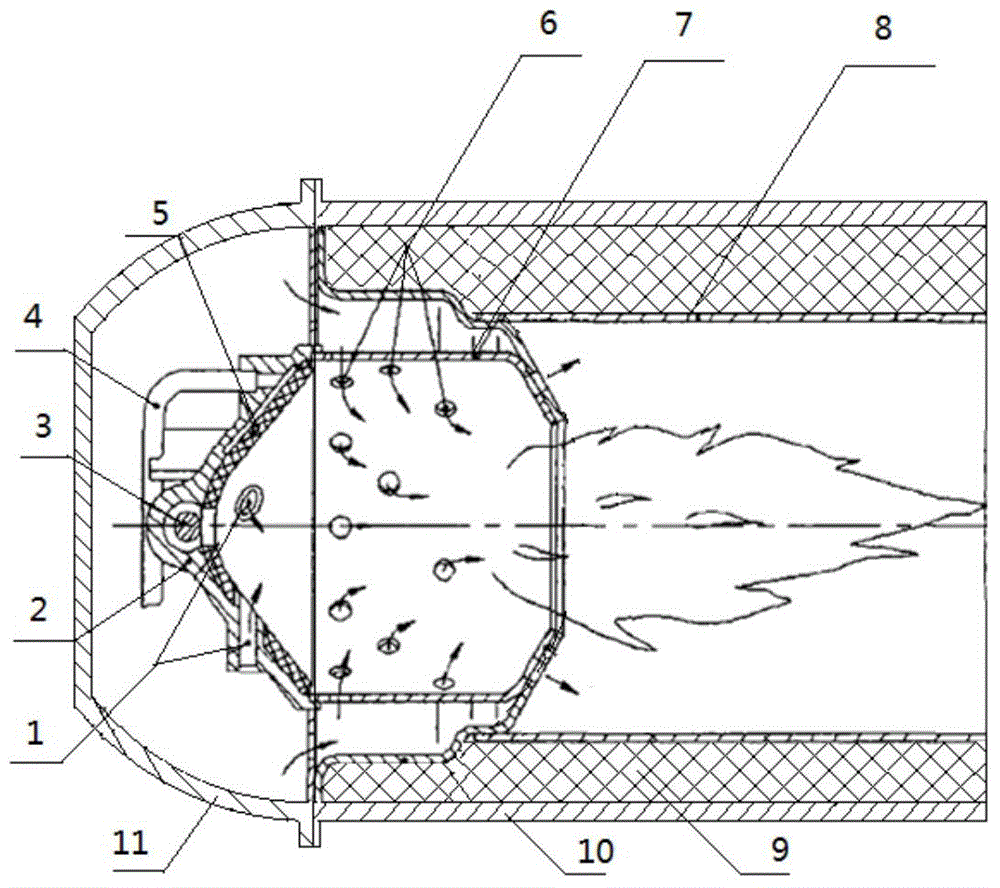

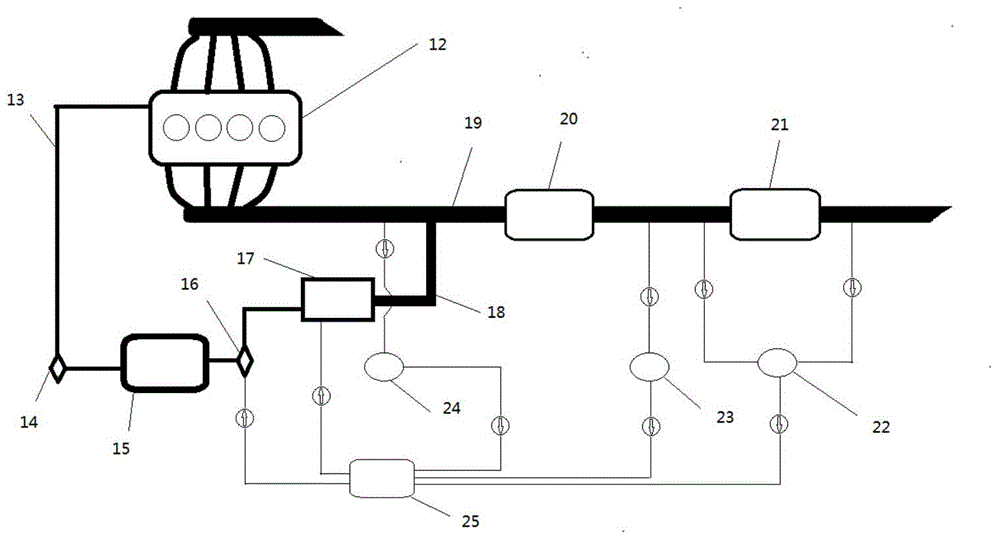

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] Such as figure 2 As shown, a DPF active regeneration system with a burner includes a burner 17, a burner oil pump 16 is arranged at the inlet end of the fuel pipe of the burner 17, and an engine oil pump 14 and a fuel tank 15 are connected in series under the engine 12. 12 Connect with the engine oil pump 14 through the engine oil circuit 13, the burner oil pump 16 and the burner 17, the engine exhaust pipe is provided with a temperature sensor and a pressure difference sensor, the output end of the electronic control unit ECU is connected with the burner oil pump 16 and the burner 17 is connected, and the burner exhaust pipe 18 communicates with the engine exhaust pipe 19.

[0022] The engine exhaust pipe 19 is connected in series with the oxidation catalyst DOC20 and the particle trapping device DPF21. The inlet end of the oxidation catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com