Diesel engine exhaust manifold fixture

A technology for diesel engines and exhaust manifolds, which is applied to exhaust devices, engine components, machines/engines, etc., and can solve the problems of large thermal load changes of exhaust manifolds and short heat transfer distances of exhaust manifolds, etc. , to achieve the effect of lowering the temperature, increasing the heat transfer distance, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

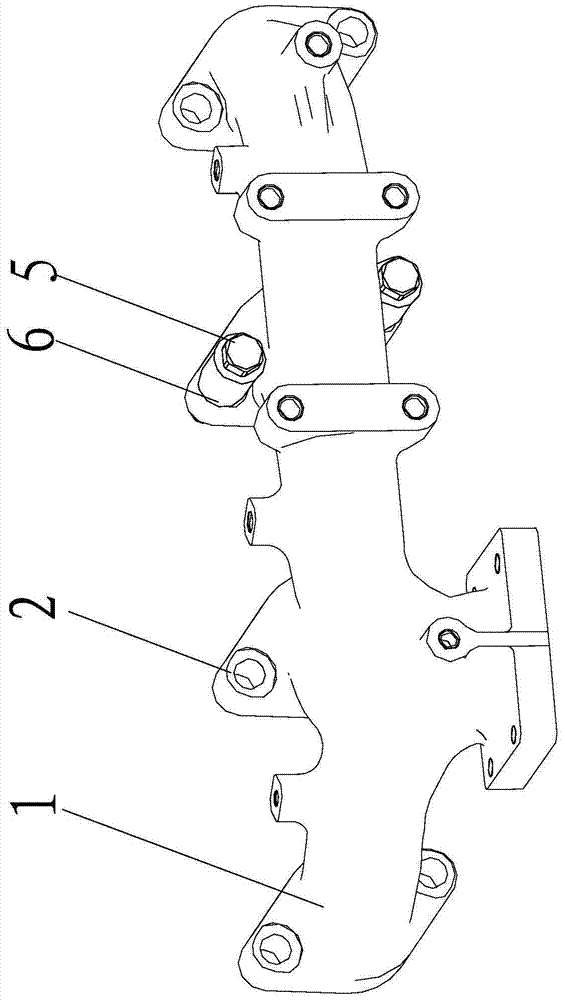

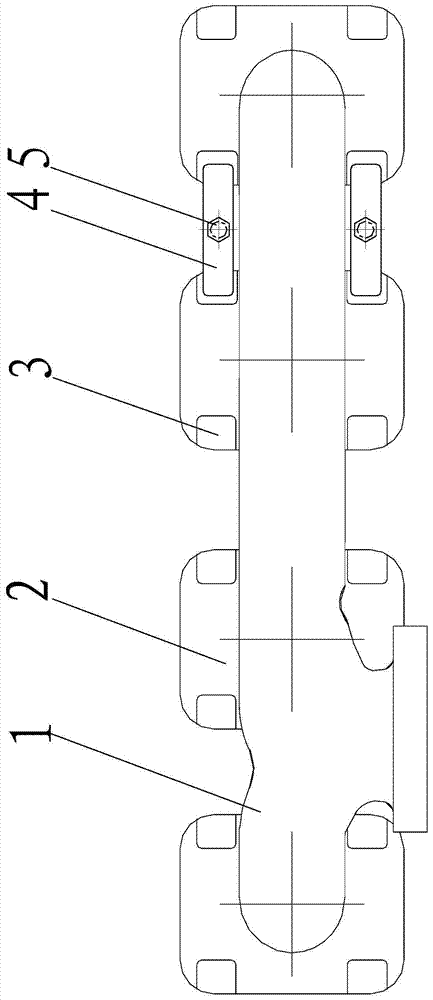

Embodiment Construction

[0010] In order to further understand the inventive content, features and effects of the present invention, the following examples are exemplified and described in detail with the accompanying drawings as follows:

[0011] like figure 2 shown,

[0012] A diesel engine exhaust manifold fixing device, comprising an exhaust manifold 1, the root of the exhaust manifold is respectively provided with fixed flanges 2 on both sides of the exhaust manifold, and the two ends of the fixed flange are respectively provided with Fixing countersink 3, the fixing countersink is adjacent to the fixing block 4, the fixing block is pierced with fixing bolts 5 through the light holes on it, the threaded part of the fixing bolt protrudes from the fixing block, and the two fixing sinks located on the adjacent fixing flanges. The holes are compressed by the same fixing block. Each exhaust manifold is fixed by four fixing blocks. In order to reflect the fixed counterbore, the four fixing blocks ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com