Full reverse flow type heat recovery device

A heat recovery device and counter-flow technology, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problem of reducing heat exchange efficiency of heat exchangers, high heat exchanger manufacturing costs, and high equipment maintenance costs problems, to achieve the effect of reducing the difficulty of production, reducing the diameter of the equipment, and increasing the installation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

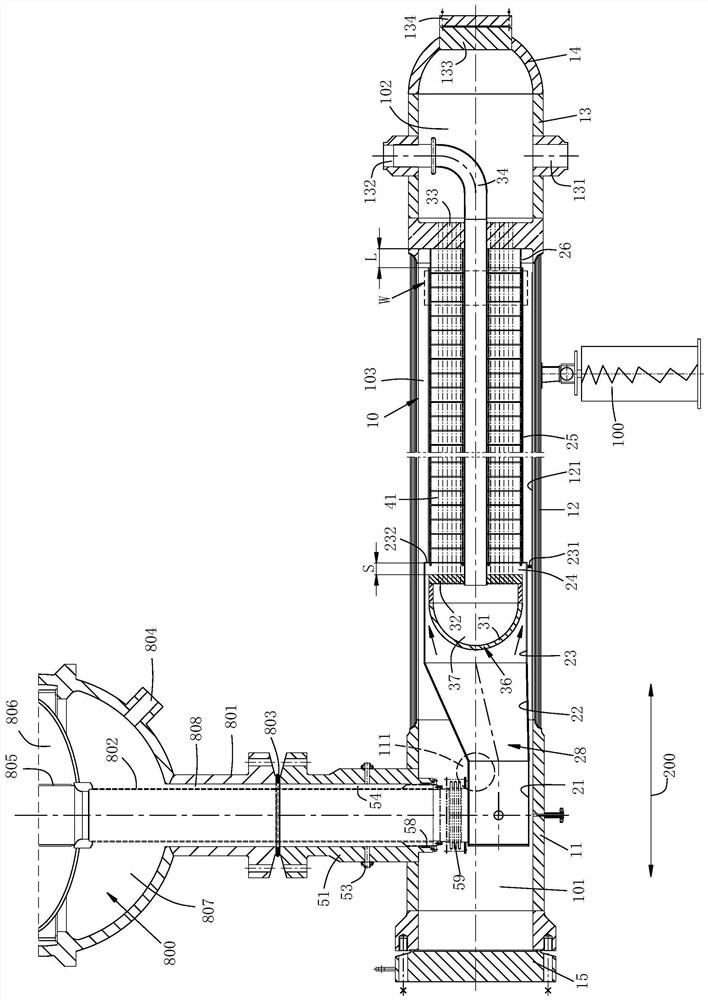

[0036] see figure 1 , figure 1 , the arrow 200 indicates the direction of the axis, which extends in the horizontal direction.

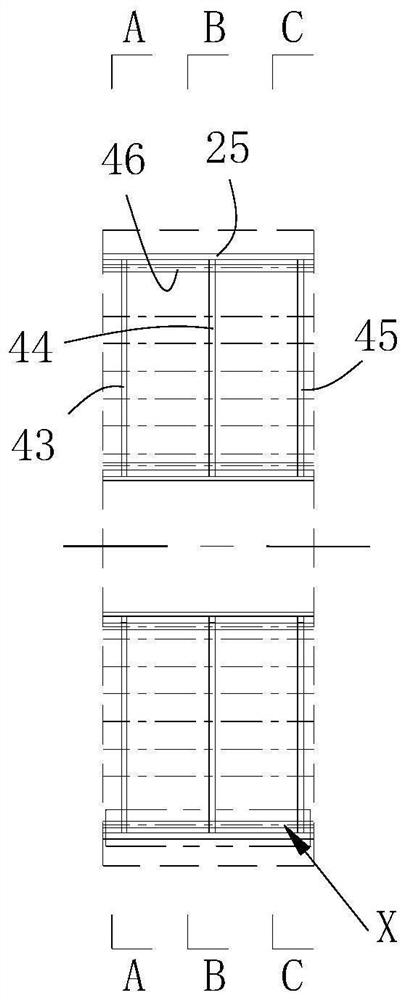

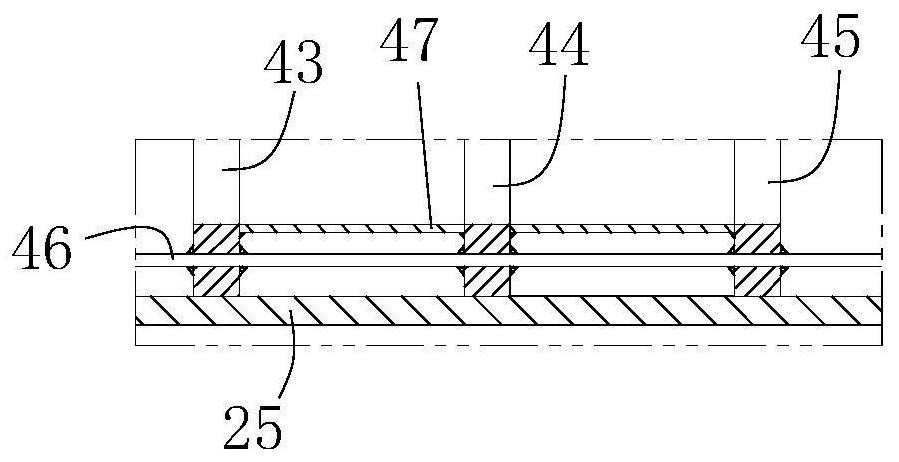

[0037] A full countercurrent heat recovery device, which includes a casing 10 extending along the axial direction, the casing includes a gas-side tube box 11, a composite cylinder 12 and a water-side tube box 13 connected in sequence, and the composite tube A divided tube sheet 33 is arranged between the body 12 and the water side tube box 13, a flat head 15 is installed at the end of the gas side tube box 11 away from the divided tube sheet, and a flat head 15 is installed at the end of the water side tube box 13 away from the divided tube sheet 33 There is a circular head 14, and a manhole 133 is opened in the center of the circular head 14, and a cover plate 134 is installed on the manhole 133, and the composite cylinder 12 is formed by laminating multiple layers of steel plates. The cylinder 12 is the bandaging cylinder in the prior art. A sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com