Chloroethylene gas compressor

A technology of gas compressors and vinyl chloride, applied in the field of compressor manufacturing, can solve problems such as leakage and achieve the effect of eliminating accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

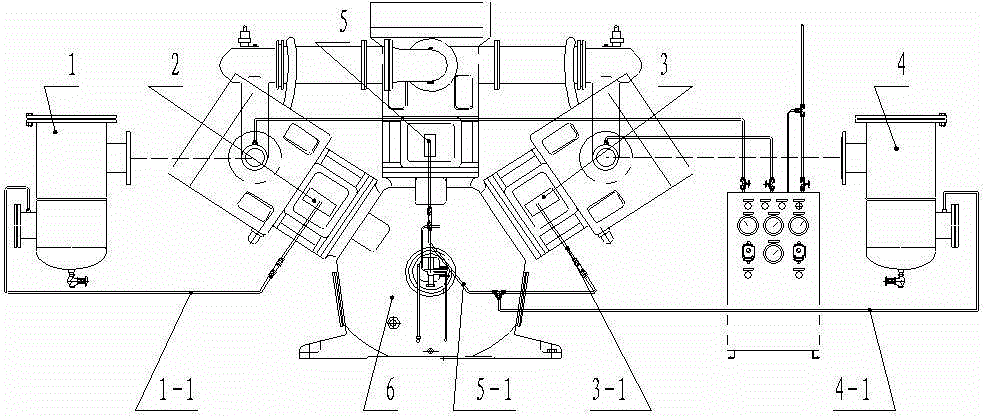

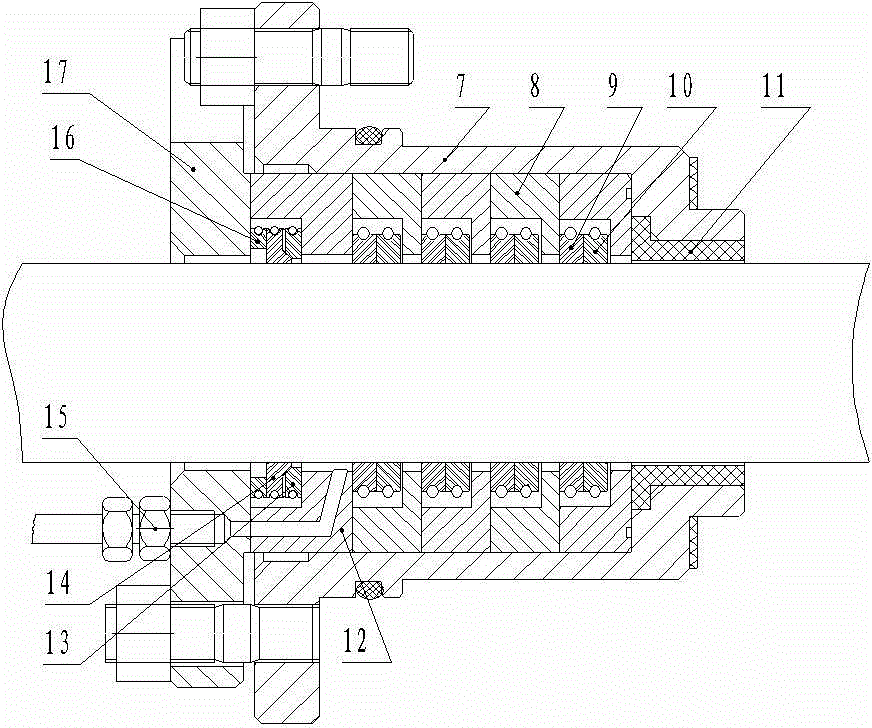

[0012] Such as figure 1 with figure 2 The shown vinyl chloride gas compressor includes a compressor host 6 provided with an intake buffer tank, and this embodiment is a WW type vinyl chloride gas compressor, which has two primary cylinders and a secondary cylinder , the intake ports of the two first-stage cylinders are respectively connected with an intake buffer tank 1 and an intake buffer tank 4; the crankshaft of the compressor host 6 is connected with three piston rods, which are respectively used to drive the piston in the three The reciprocating piston rods in each cylinder are equipped with a packing device outside each piston rod. The three packing devices are respectively the packing device 2 of the first-stage cylinder, the packing device 3 of the first-stage cylinder, and the packing device of the second-stage cylinder. 5. These packing devices all inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com