Thermosensitive detonating tube

A technology of sensitive explosion tube and cavity, which is applied in the field of pyrotechnics to achieve the effect of avoiding physical explosion and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

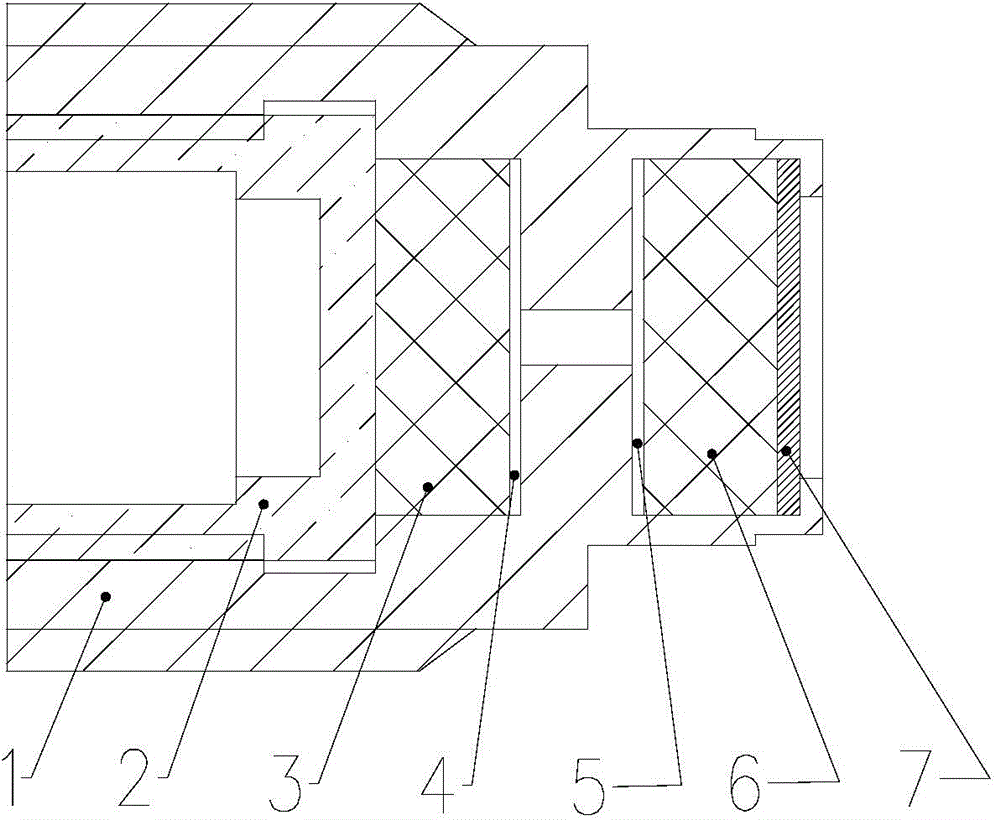

[0016] Such as figure 1 As shown, a heat-sensitive squib includes a base 1, a nut 2, a charging chamber A3, an aluminum foil A4, an aluminum foil B5, a charging chamber B6 and a gasket 7, and the base 1 is a heat-sensitive squib The skeleton of the seat body 1 is provided with external threads to realize the connection with the high-pressure gas tank, gas cylinder or automatic valve on it; the interior of the seat body 1 is divided into two parts by a partition with a small hole in the middle, A part of it is provided with an internal thread and a charge cavity A3, and the nut 2 cooperates with the internal thread, and the charge cavity A3 is located between the nut 2 and the interlayer, and the other part is provided with a charge cavity B6, The aluminum foil A4 and the aluminum foil B5 are respectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com