Modular split type LED ring illuminator and manufacturing method thereof

A technology of LED light source and ring light source, applied in the field of modular split LED ring light source and its preparation, can solve the problems of heat dissipation structure, unbalanced heat dissipation effect, asynchronous aging speed of LED, and shortening service life of ceiling lamps, etc. The effect of LED glare phenomenon, improving light efficiency utilization, and simplifying assembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

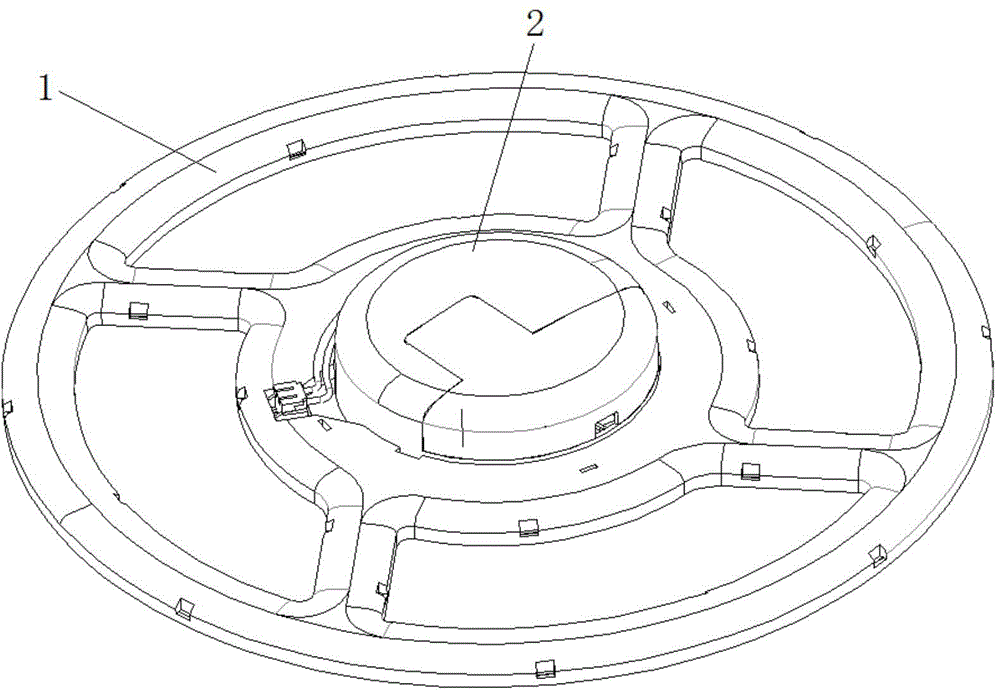

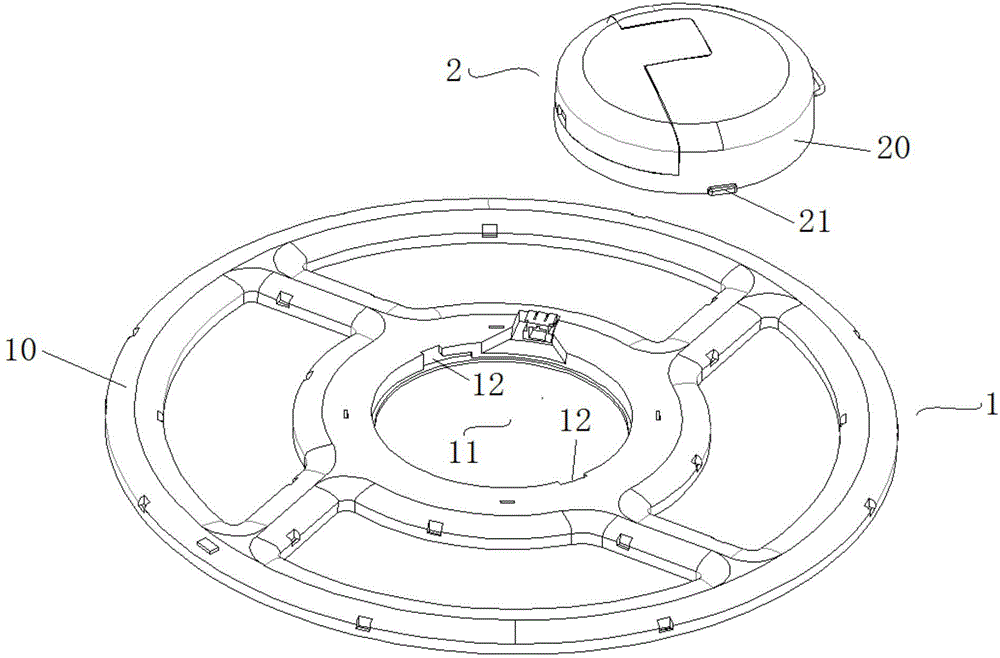

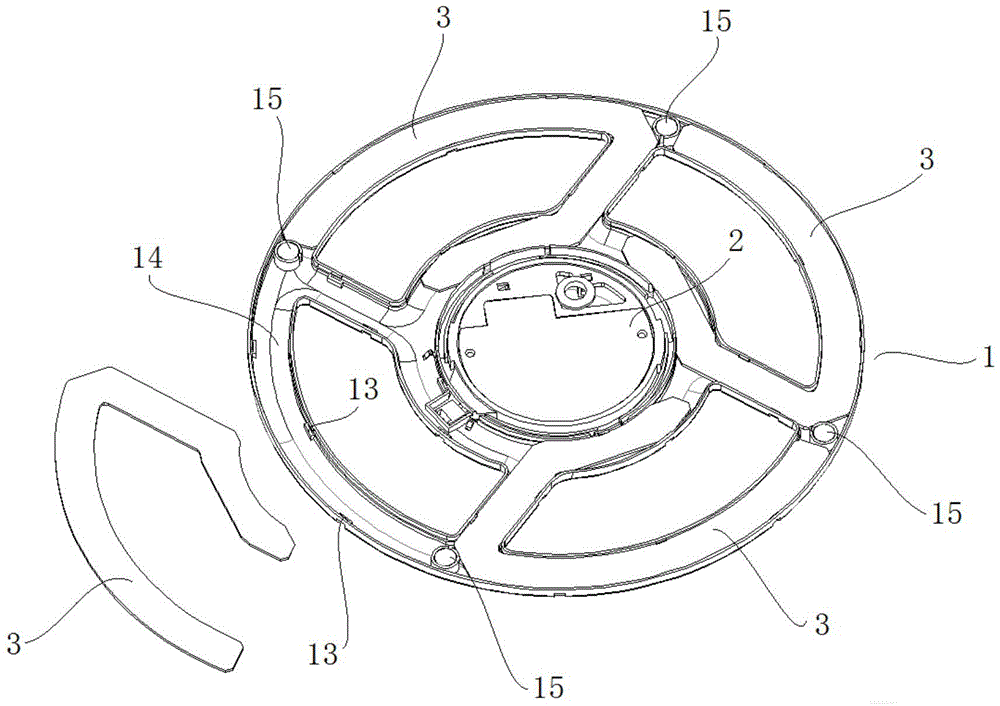

[0045] Example: see Figure 1 to Figure 6, the modular split-type LED ring light source provided in this embodiment includes a light-transmitting protective cover 1, a driving power supply 2 and multiple groups of LED light source modules 3; the light-transmitting protective cover 1 includes a The cavity surface 14 of the module 3, the driving power supply 2 is installed on the light-transmitting protective cover 1, and is detachably connected with the light-transmitting protective cover 1, and each group of LED light source modules 3 is electrically connected with the driving power supply 2, each The groups of LED light source modules 3 are all detachably arranged on the cavity surface 14 of the light-transmitting protective cover 1, and multiple groups of LED light source modules 3 are respectively arranged around the cavity surface 14 of the light-transmitting protective cover 1, and are center-symmetrical and evenly distributed. The overall center of gravity inside the LED...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com