Automatic wheel hub cover opening height detection mechanism

An automatic detection and hub cap technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as difficult detection, shutdown, detection errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

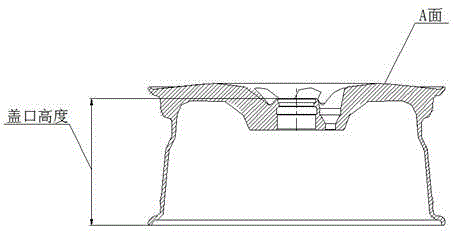

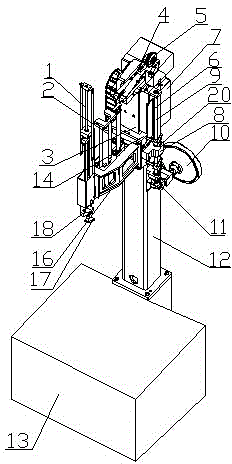

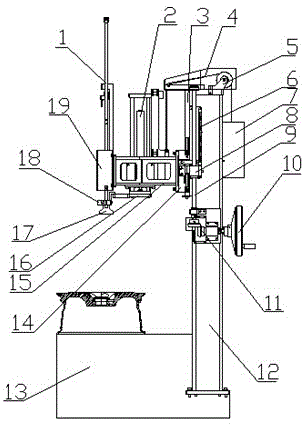

[0014] Depend on figure 1 , figure 2 , image 3 Known, a hub cover opening height automatic detection mechanism is composed of a linear encoder 1, a cylinder 2, a guide rail 3, a steel wire 4, a pulley 5, a scale 6, a counterweight 7, a lifting screw female seat 8, a screw rod 9, and a hand wheel 10 , gear pair 11, column 12, base 13, slide block 14, lifting movable seat 15, cylinder connecting plate 16, detection head 17, detection head mounting plate 18, detection head lifting guide block 19, locking screw rod 20 composition. The column 12 is installed on the base 13, the lifting movable seat 15 is installed on the slide block 14 and cooperates with the guide rail 3, the guide rail 3 is installed on the column 1, the lifting screw female seat 8 is connected with the lifting movable seat 15, and the screw rod 9 is installed on the In the lifting screw female base 8, one end of the screw rod 9 is connected to the gear pair 11, the hand wheel 10 is installed on the gear pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com