Wind turbine blade coating erosion and wear experiment table

A technology of wind turbine blades and test benches, applied in the direction of testing wear resistance, etc., can solve the problems that cannot meet the needs of wind turbine blade coating erosion and wear research, and achieve the effect of safe use, convenient maintenance and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

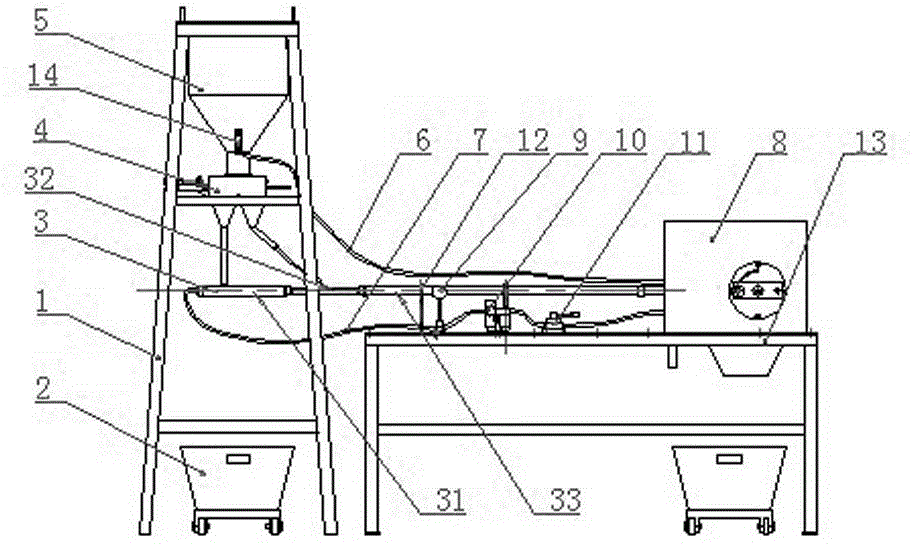

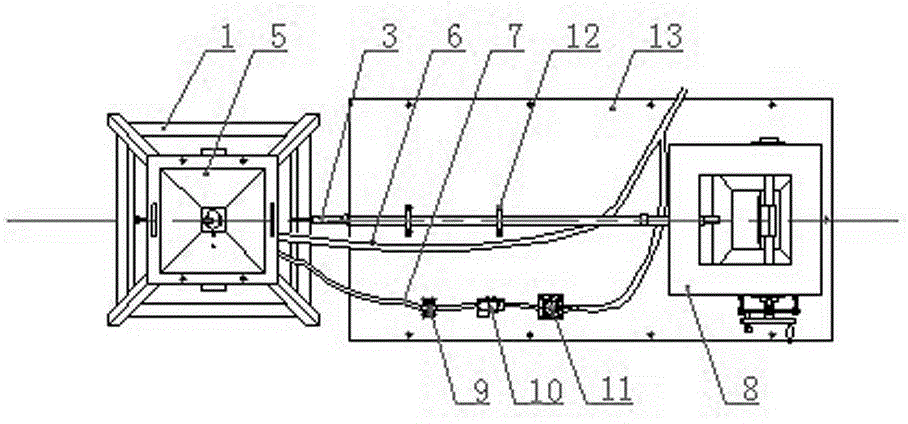

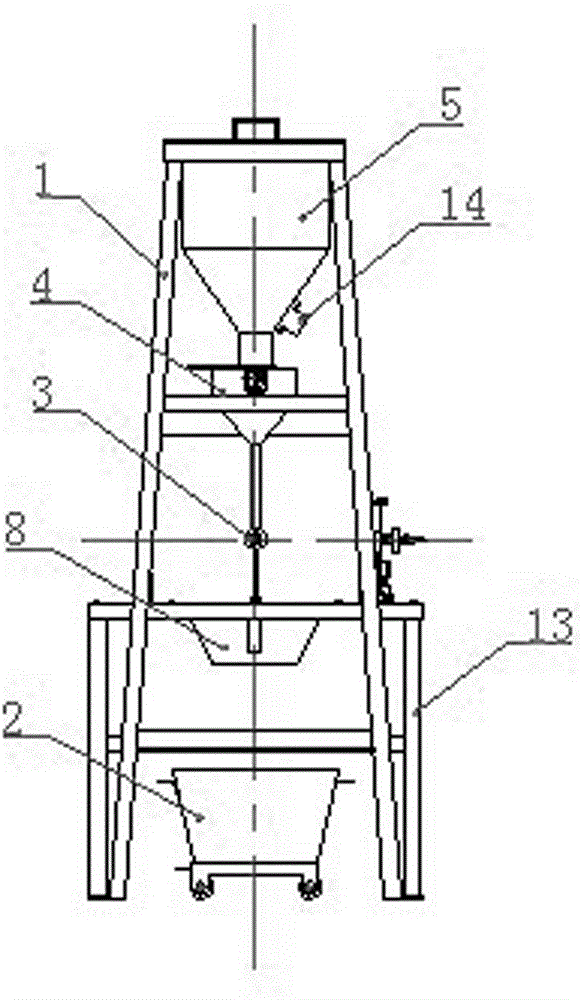

[0032] see Figure 1 to Figure 17 , a wind turbine blade coating erosion and wear test bench according to the present invention, comprising a sand box 5, a sand separation device 4, a sand collecting trolley 2, an erosion pipe 3, an air compressor (not shown), a flow meter 9, Pressure reducer 10, air valve 11, erosion box 8 and test bench, the lower port of the sand box is connected to the upper end of the sand distribution device, and the sand volume adjustment plate is at the connection; the lower end outlet of the sand distribution device is connected to the front of the erosion pipe. The front end of the erosion pipe is connected to the air outlet of the air compressor through a flow meter, a pressure reducer and an air valve connected in series, and the rear end of the erosion pipe is connected to the inlet on one side of the erosion box. Connection; the various devices except the air compressor are installed on the test bench, and a sand collecting trolley is arranged un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com