Test method of bonding strength of composite insulator

A composite insulator and bonding strength technology, applied in the direction of measuring devices, instruments, and mechanical devices, can solve problems such as partial discharge at the interface, composite insulator fracture, core rod and sheath aging, etc., to avoid partial discharge, Avoid aging and corrosion, the effect of simple and easy equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

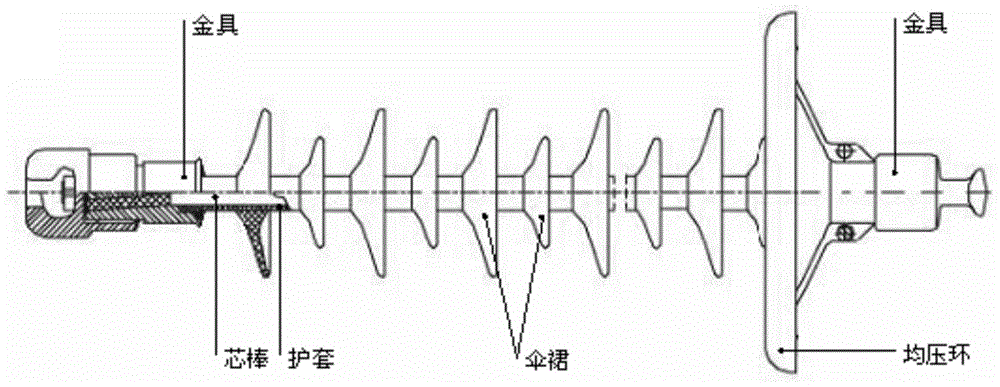

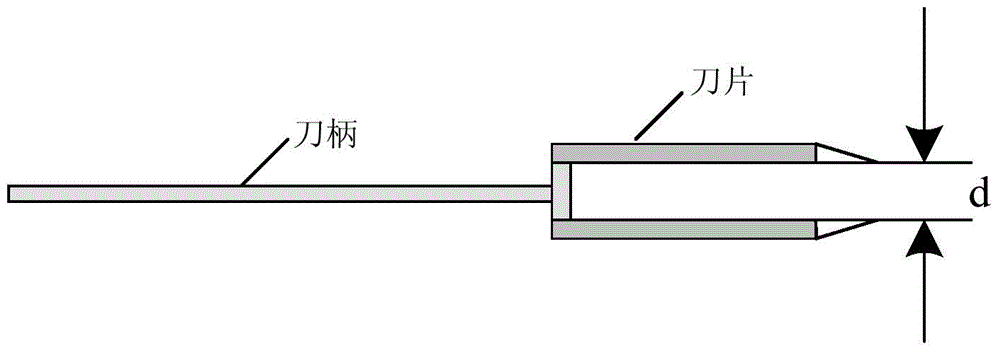

[0033] like Figure 1-2 As shown, the invention of this example provides a method for testing the bonding strength of composite insulators, figure 1 It is a typical composite insulator, the fittings are fixed on both ends of the mandrel (glass fiber epoxy resin) by crimping, the insulating sheath (silicone rubber) is bonded to the mandrel, and the sheath (silicone rubber) is bonded to the sheath. The method is suitable for testing the bond strength between the composite insulator sheath and the mandrel and the test of the bond strength between the shed and the sheath of the composite insulator;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com