Electric zoom, focus 7-22 zoom monitor lens and control method thereof

A lens, motorized technology, applied in focusing devices, focusing devices, focusing devices of cameras, etc., can solve the problems of low focusing accuracy, small number of steps, and complicated production, and achieve high resolution, short structure length, and wide spectrum. Confocal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

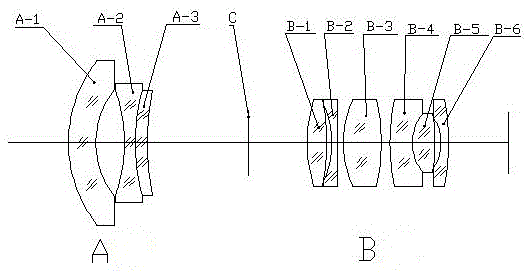

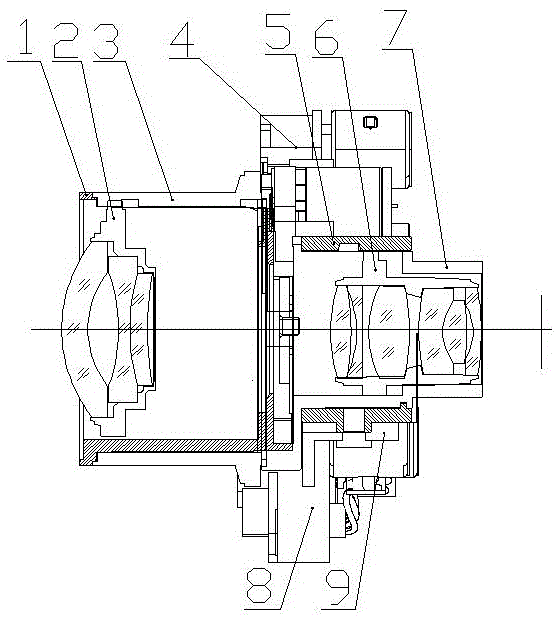

[0018] Such as Figure 1~2 As shown, a motorized zoom, focusing 7-22 zoom monitoring lens, the mechanical structure of the lens includes a front group lens mount 2 for installing the front group A and a rear group mirror mount 6 for installing the rear group B, so The front lens holder 2 is movably installed in the front lens barrel 1, and the front lens barrel 1 is covered with a front fan-shaped cam 3 that drives the front lens holder 2 to move back and forth, and the rear lens holder 6 is movable. Installed in the rear group lens barrel 7, the outer side of the rear group lens barrel 7 is provided with a rear cam 5 that drives the rear group lens holder 6 to move back and forth, and the front group lens barrel 1 and the rear group lens barrel 7 respectively pass through two The main body guide nail is connected with the reduction box 8; the focus stepping motor and the zoom stepping motor are arranged in the reduction box 8, and the output gear of the focus stepping motor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com