Display panel, display panel manufacturing method and display

A technology for display panels and array substrates, applied in the directions of instruments, nonlinear optics, optics, etc., can solve the problems of broken metal data lines 13 and increased defect rate of products, and reduce the number of metal grids, reduce defect rate, reduce Effect of Fracture Chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

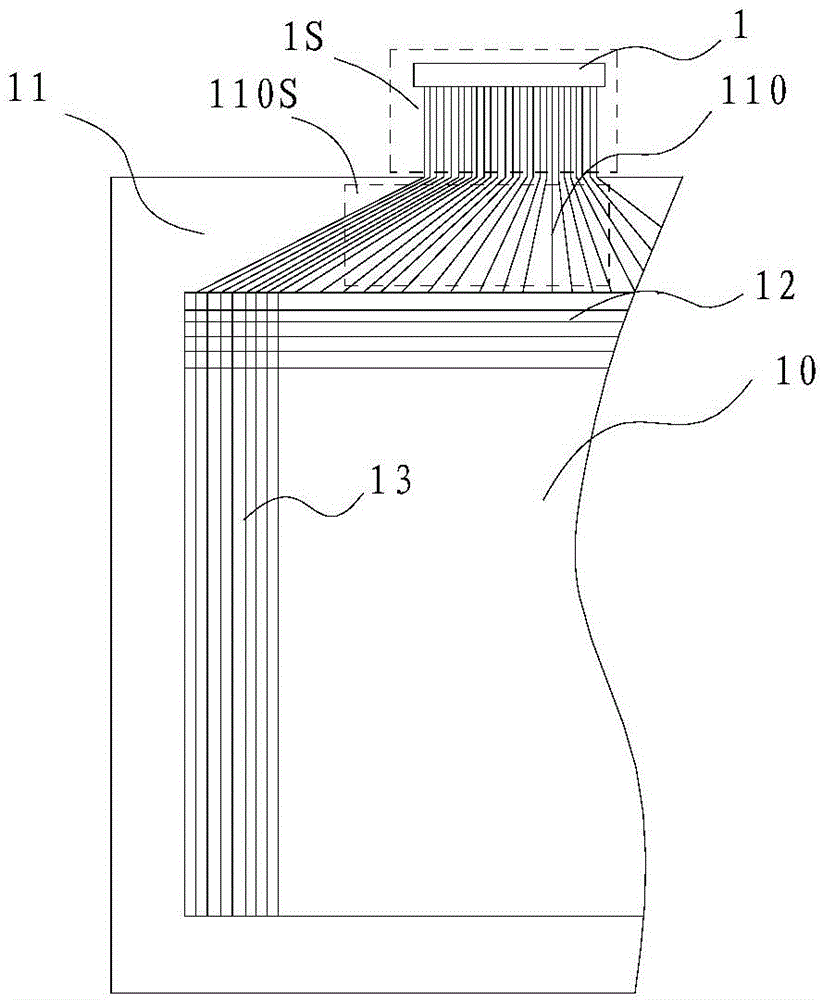

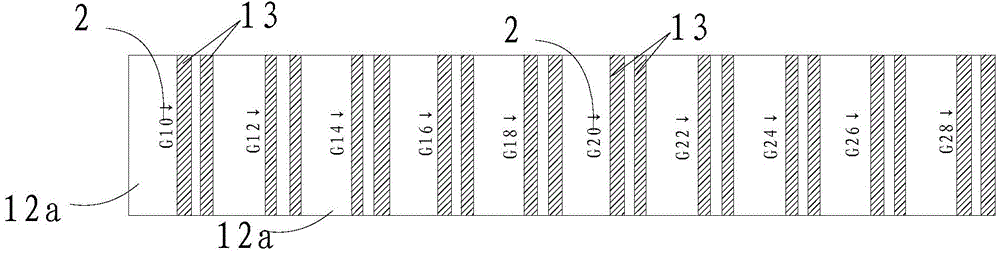

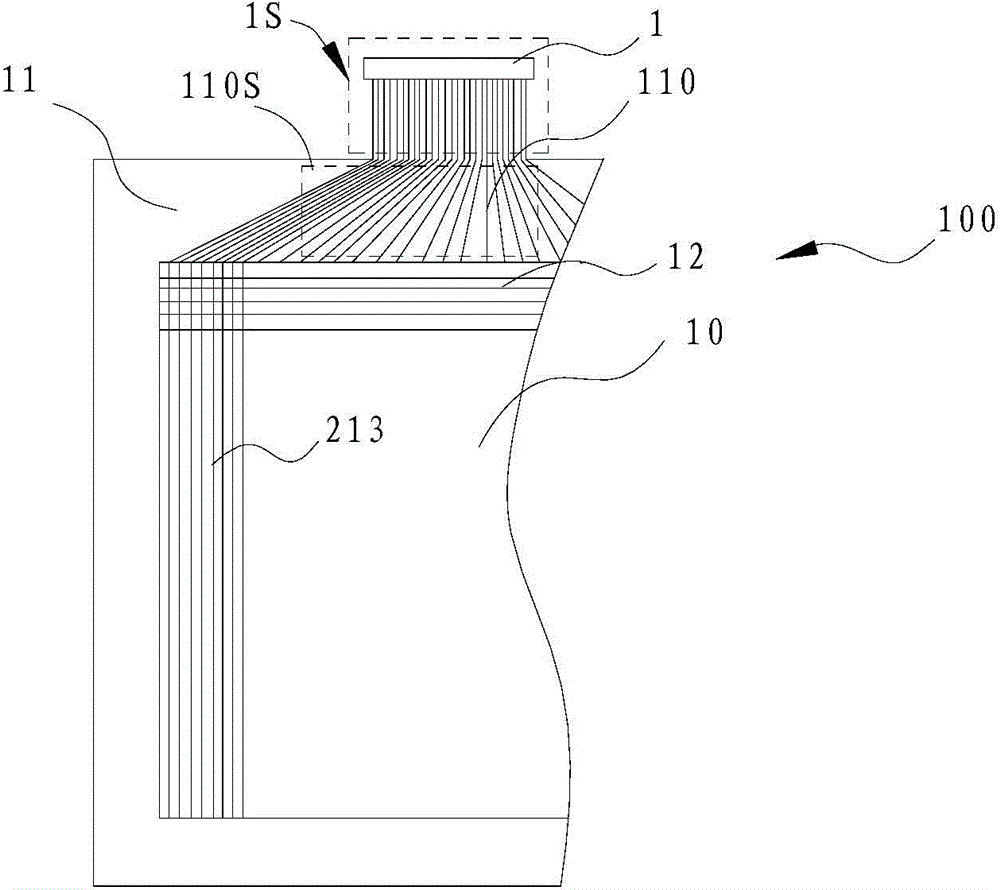

[0027] like image 3 As shown, the display panel 100 of the embodiment of the present invention includes an active area 10 and a peripheral circuit area 11. The active area 10 has pixel units and is provided with a plurality of parallel and spaced data lines 213; the peripheral circuit area 11 does not have pixels unit, and is provided with a fan-out lead 110 for connecting the driver chip 1 . combine Figure 4 , wherein, the TFT array substrate (not shown) includes a glass substrate 212S, a gate 212a, two insulating layers 212d, a transparent conductive film (ie ITO) layer 212b and a source e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com