Electric slag furnace monitoring system based on wireless sensor network

A wireless sensor network and monitoring system technology, applied in signal transmission system, network topology, wireless communication, etc., can solve the problems of low production efficiency, high cost, unsuitable for centralized monitoring of large steelmaking plants, etc., and achieve simple structure, The effect of low input cost and reducing the influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

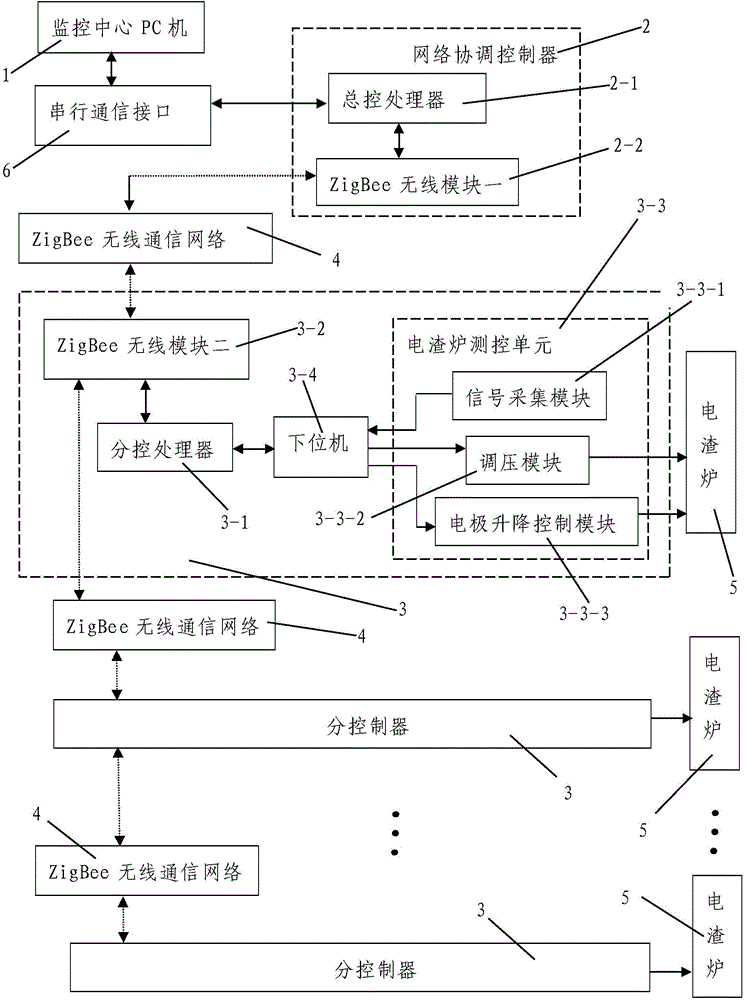

[0025] like figure 1 As shown, the present invention includes the monitoring center PC 1 that is internally provided with a configuration monitoring module, a report automatic generation module and an alarm module, a network coordination controller 2 that carries out information transmission with the monitoring center PC 1 through a serial communication interface 6, and A plurality of sub-controllers 3 connected to the network coordination controller 2 through the ZigBee wireless communication network 4, the number of the plurality of sub-controllers 3 is equal to the number of electroslag furnaces 5 . Described network coordination controller 2 comprises general control processor 2-1 and ZigBee wireless module one 2-2, and described general control processor 2-1 joins with serial communication interface 6 and ZigBee wireless module one 2-2 respectively , the ZigBee wireless module one 2-2 is connected to the sub-controller 3 through the ZigBee wireless communication network 4...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap