Inertia stick-slip cross-scale motion platform capable of achieving unidirectional movement

A motion platform, cross-scale technology, applied in the directions of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problems of difficult control, damage to the mechanism, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

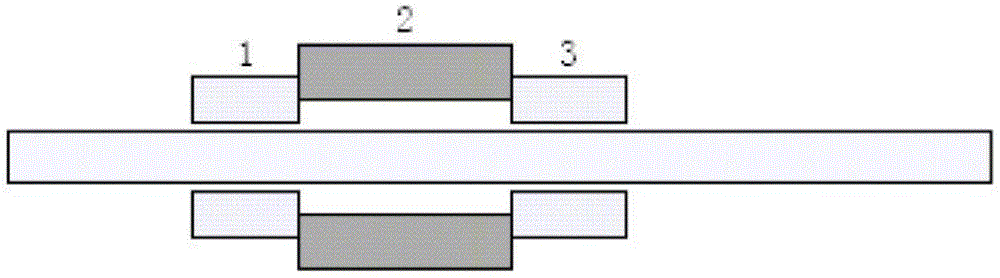

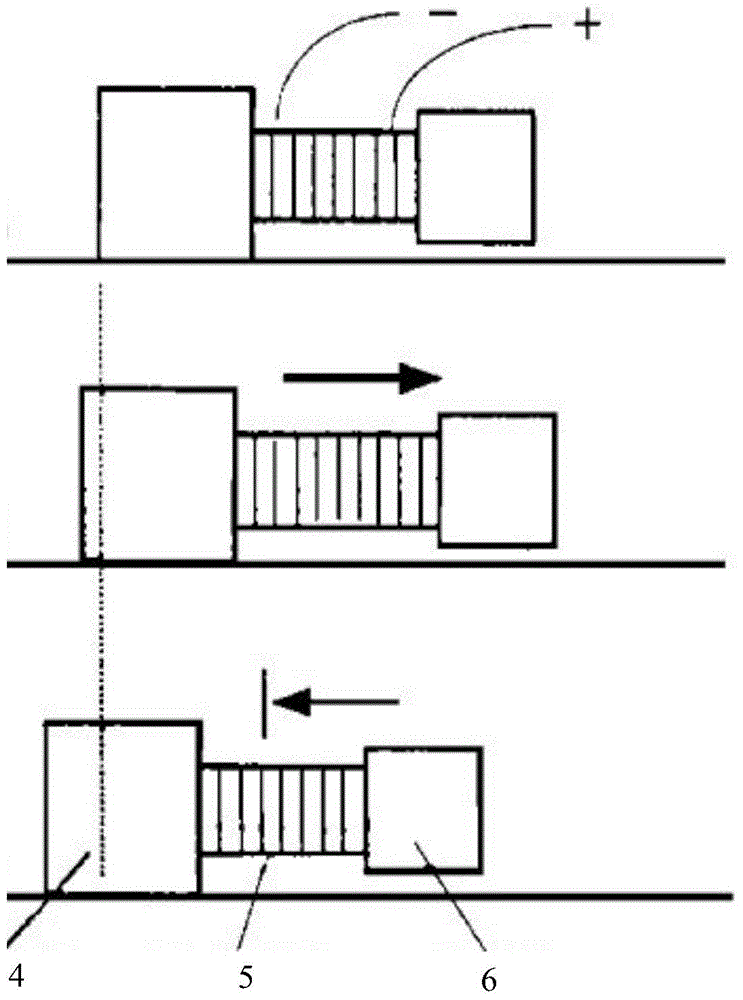

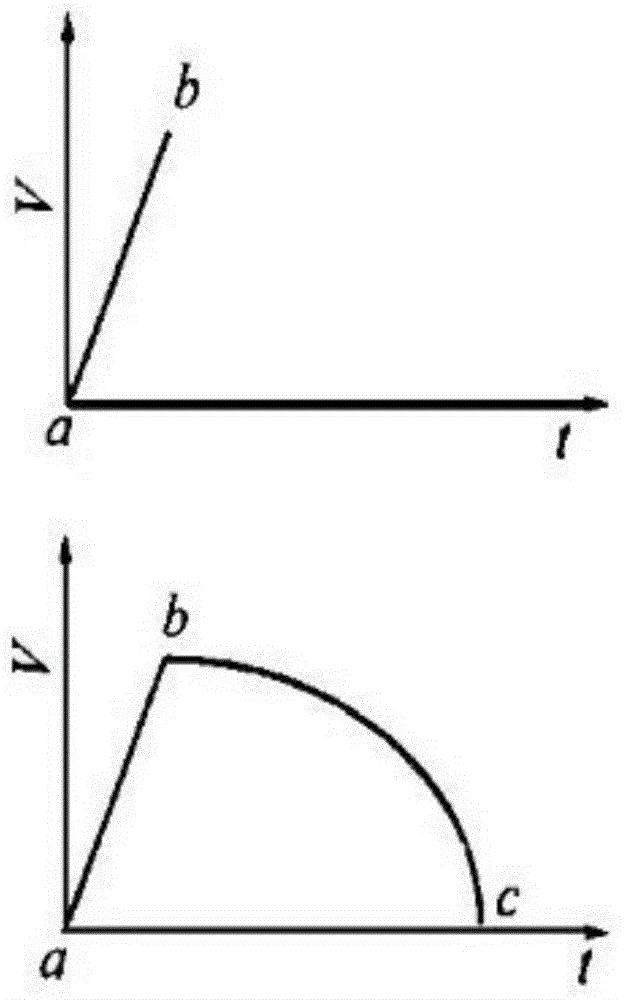

[0032] figure 2 It is a schematic diagram of the motion process of the inertial stick-slip cross-scale motion platform that realizes one-way motion provided by the preferred embodiment of the present invention. Such as figure 2As shown, the inertial stick-slip cross-scale motion platform for one-way motion provided by the preferred embodiment of the present invention includes a main mass 4, a piezoelectric ceramic actuator 5 and a counterweight 6, and the piezoelectric ceramic actuator Both ends of the device 5 are connected to the main mass 4 and the counterweight 6 respectively. The piezoelectric ceramic actuator 5 is used to slightly elongate or shorten in the length direction when a forward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com