Circuit board processing method

A processing method and technology for circuit boards, which are applied in printed circuits, printed circuit manufacturing, and chemical/electrolytic methods to remove conductive materials, etc., can solve the problem that it is difficult to process high-precision and fine lines from thick copper circuit boards, and achieve good results. Etching, improving etching accuracy, inhibiting side etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

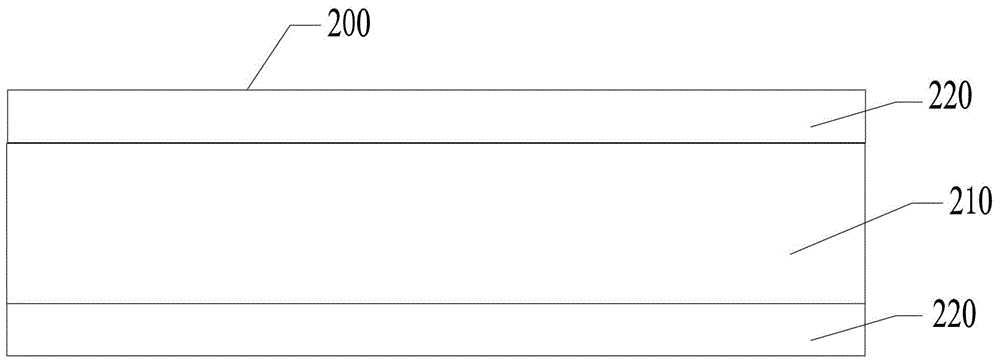

[0013] The embodiment of the present invention provides a method for processing a circuit board, which can solve the technical problem that it is difficult to process high-precision and fine lines for thick copper circuit boards using the prior art. A detailed description will be given below in conjunction with the accompanying drawings.

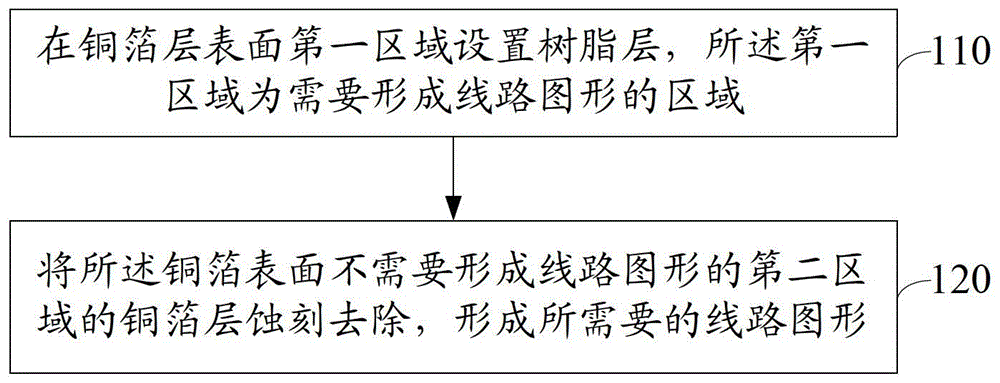

[0014] Please refer to figure 1 , the embodiment of the present invention provides a circuit board processing method, comprising:

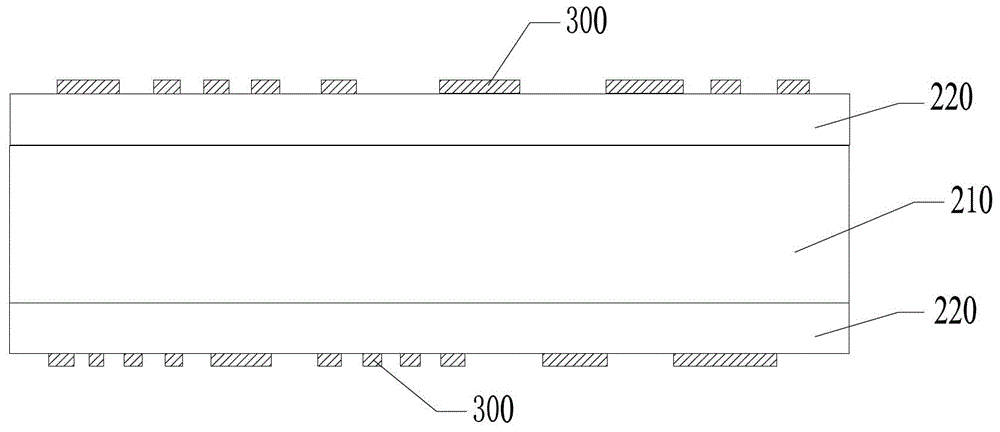

[0015] 110. Arrange a resin layer on a first area on the surface of the copper foil layer, and the first area is an area where circuit patterns need to be formed.

[0016] In the embodiment of the present invention, resin is used instead of dry film as the anti-corrosion protection layer, which is mainly suitable for thick copper circuit boards with a copper thickness greater than or equal to 3 OZ, so as to improve the etching accuracy for thick copper circuit boards.

[0017] In one embodiment, before step 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com