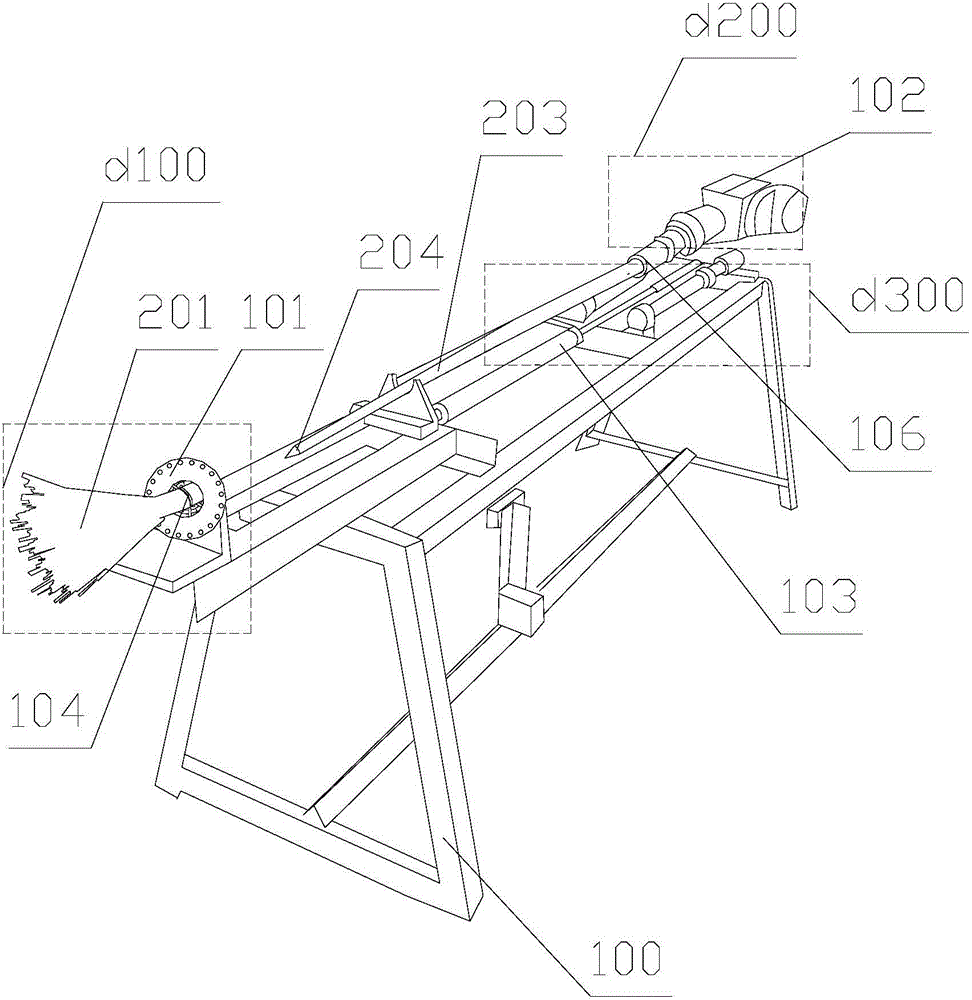

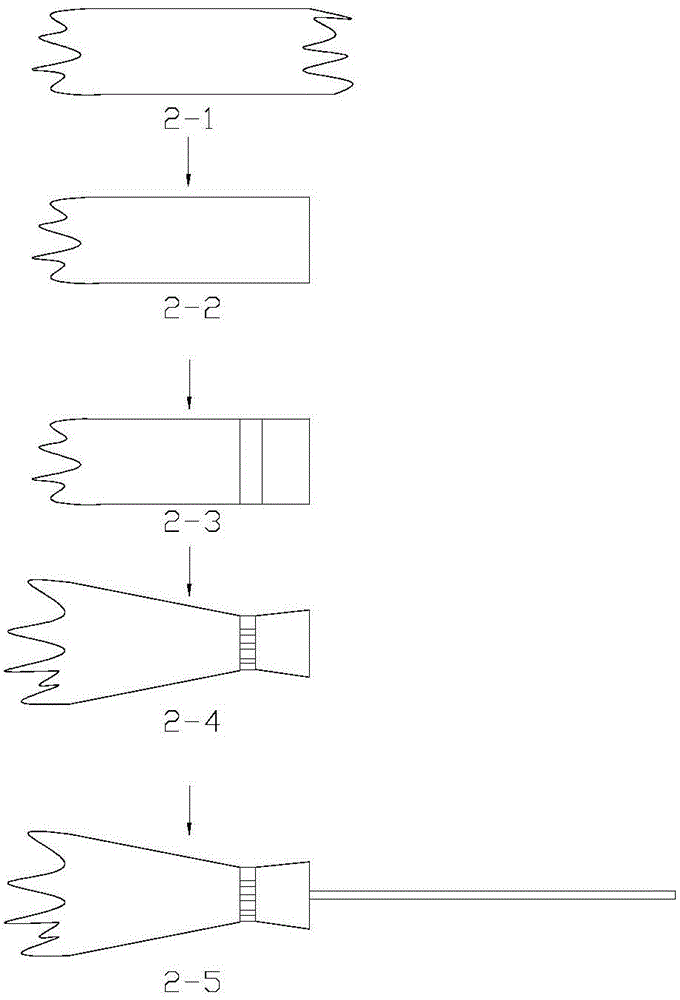

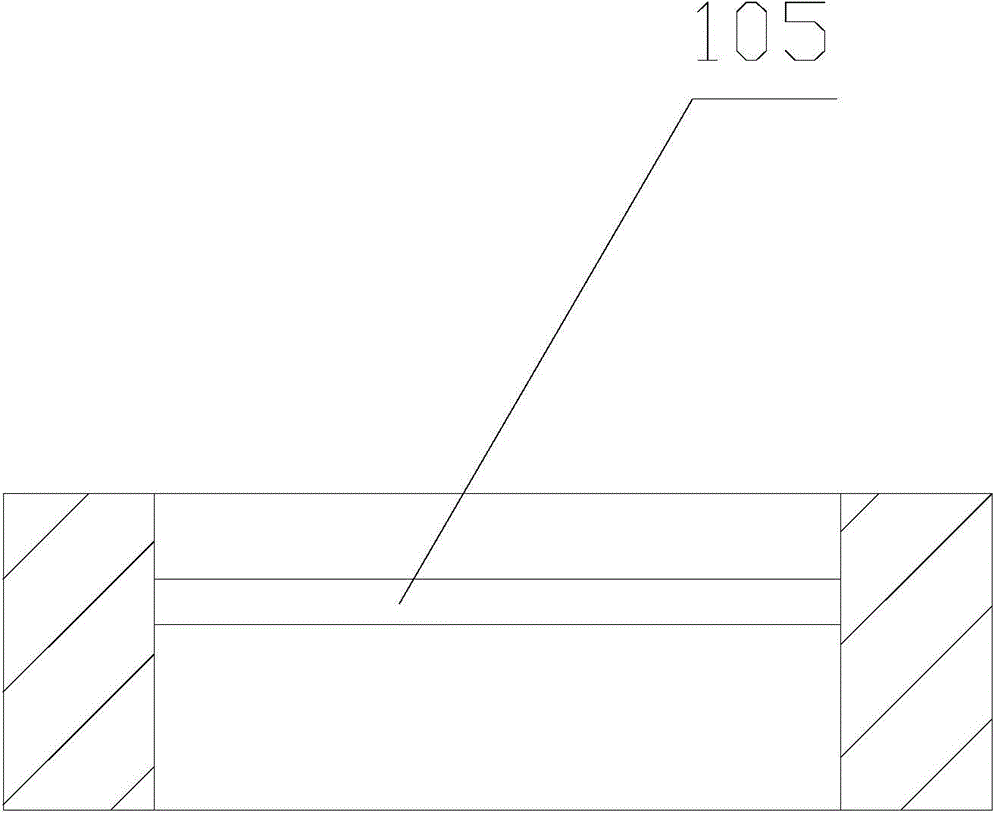

Broom manufacturing method and equipment

A production method and broom technology, which are applied to cleaning equipment, carpet cleaning, floor cleaning, etc., can solve the problems of short service life of brooms and no processing procedures for brooms, and achieve the effect of simple installation and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Brooms are used very frequently in our daily life. The existing brooms are mostly made of plastic or plant stems. The plastic brooms are not easy to decompose after being discarded because they cannot be used, resulting in environmental pollution; the existing use of plants There is no mature processing method and equipment for making brooms from stems, and most of them are handmade. The broom head is fixed with iron wire or bamboo strips by hand. The production process is time-consuming and laborious, and the fixation of the broom head and handle is not strong. , The raw material of the broom head is easy to fall off, and the handle is easy to slip off from the broom head, which is inconvenient to use and has a short service life.

[0040] In view of this, the designer of the present invention has designed a broom making method and equipment, which have the advantages of high efficiency, high quality and low cost compared with the traditional broom making method.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com