Novel pipeline gas-liquid separator

A technology of liquid separator and pipeline gas, applied in the field of pipeline gas-liquid separator, can solve the problems of complex structure, low separation efficiency, large volume of natural gas gas-liquid separator, etc. Effect of gas-liquid contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

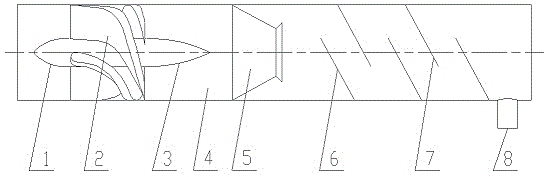

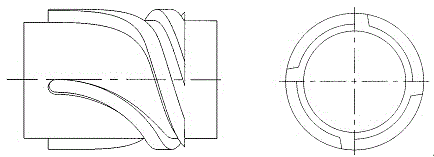

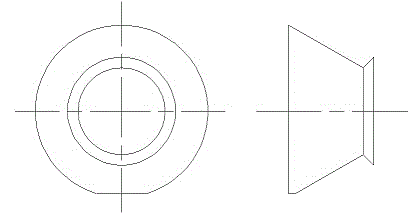

[0018] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, the novel pipeline gas-liquid separator of the present invention includes a hydrocyclone separation component and a mechanical trapping component arranged in the pipeline. The hydrocyclone separation components include a steady flow spinner, a separation cylinder (4) and a separation cone (5), and the steady flow spinner consists of a guide (1), a guide vane (2) and a steady flow cone (3); The mechanical trapping parts include front bow-shaped plates (6) and rear bow-shaped plates (7) which are staggered and inclined. Elongated grooves (9) are provided. In this embodiment, the total number of bow-shaped plates is preferably 5. The slotting directions of the front and rear bow-shaped plates are staggered, and the stagger angle is 45-90°, preferably 90° in this embodiment. A liquid collecting pipe (8) is arranged on the pipeline behind the arcuate plate.

[0019] When in use, the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com