Efficient wet dust remover

A technology of wet dust collector and dust collector, which is applied in the direction of chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of poor dust removal effect, achieve good purification effect, increase contact area, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

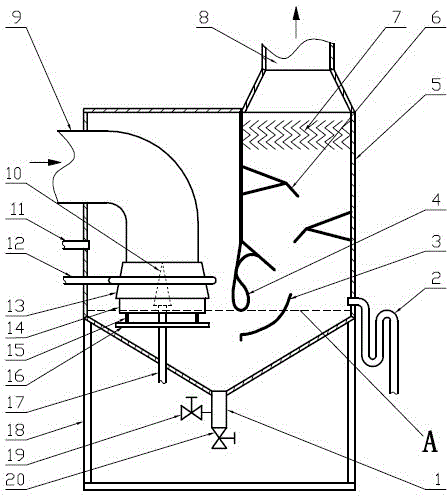

[0023] Such as figure 1 As shown, the high-efficiency wet dust collector includes a support frame 18, a dust collector box 5 located on the support frame 18, an air inlet pipe 9 extending into the side of the dust collector box 5 and fixed, and a dust collector box On the other side of the body 5 is an S-shaped channel composed of upper blades 4, lower blades 3, and water baffles 6, and an exhaust pipe 8 connected to the top of the dust collector box 5, and located at the bottom of the dust collector box 5. The slurry discharge pipe 1, the slurry discharge valve 20 and the flushing valve 19 connected with the slurry discharge pipe 1, and the water supply pipe 11 and the overflow pipe 2 communicated with the dust collector box 5. The exhaust pipe 8 is fixed on the top wall of the dust collector box 5, and the air inlet pipe 9 enters the box from the side wall of the dust collector box 5 and is fixedly connected with the side wall of the dust collector box 5. The outlet of the ...

Embodiment 2

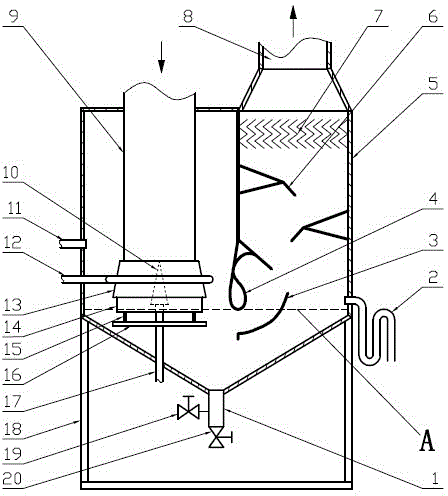

[0027] Such as figure 2 As shown, the inlet pipe 9 of the high-efficiency wet dust collector enters the box body from the top wall of the dust collector box 5 and is fixedly connected with the top wall of the dust collector box 5 . Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com