Support drill jig structure for drilling double lug piece part

A technology for drilling dies and parts, applied in the field of supporting drilling dies, can solve the problems of not being able to support and self-lock at the same time, low manufacturing cost, easy to vibrate, etc., and achieve the effects of great practical value, low manufacturing cost and good practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

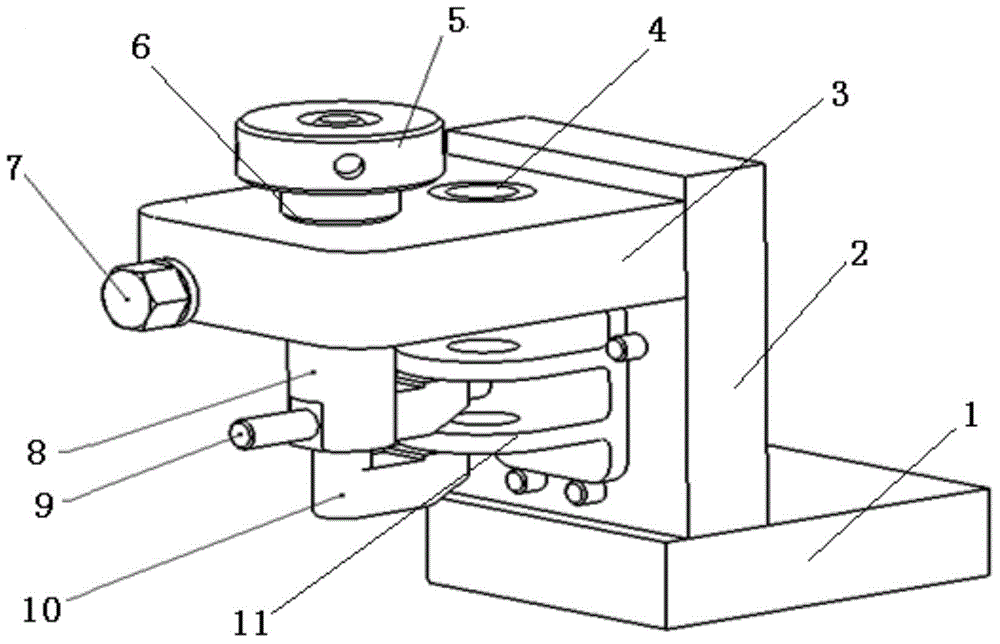

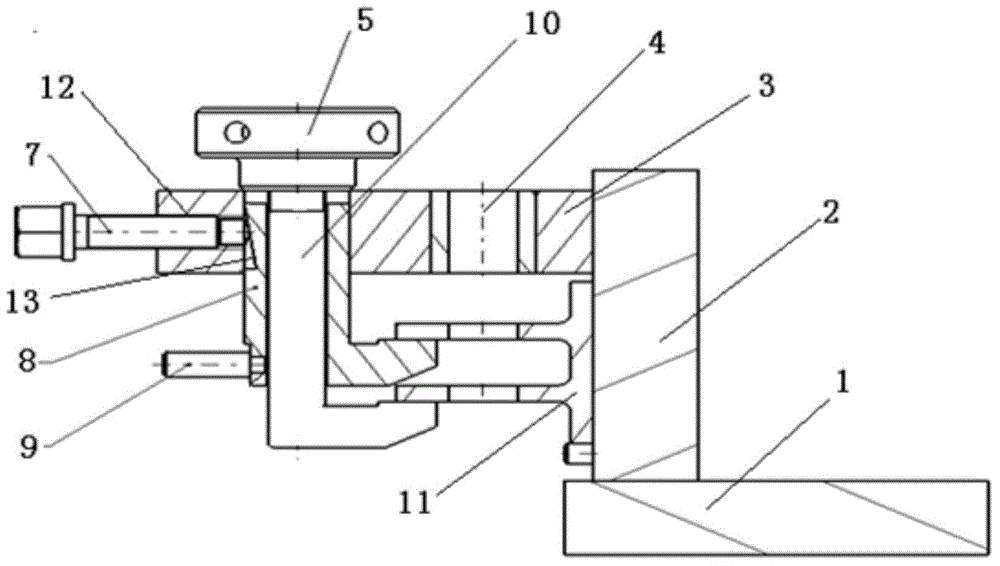

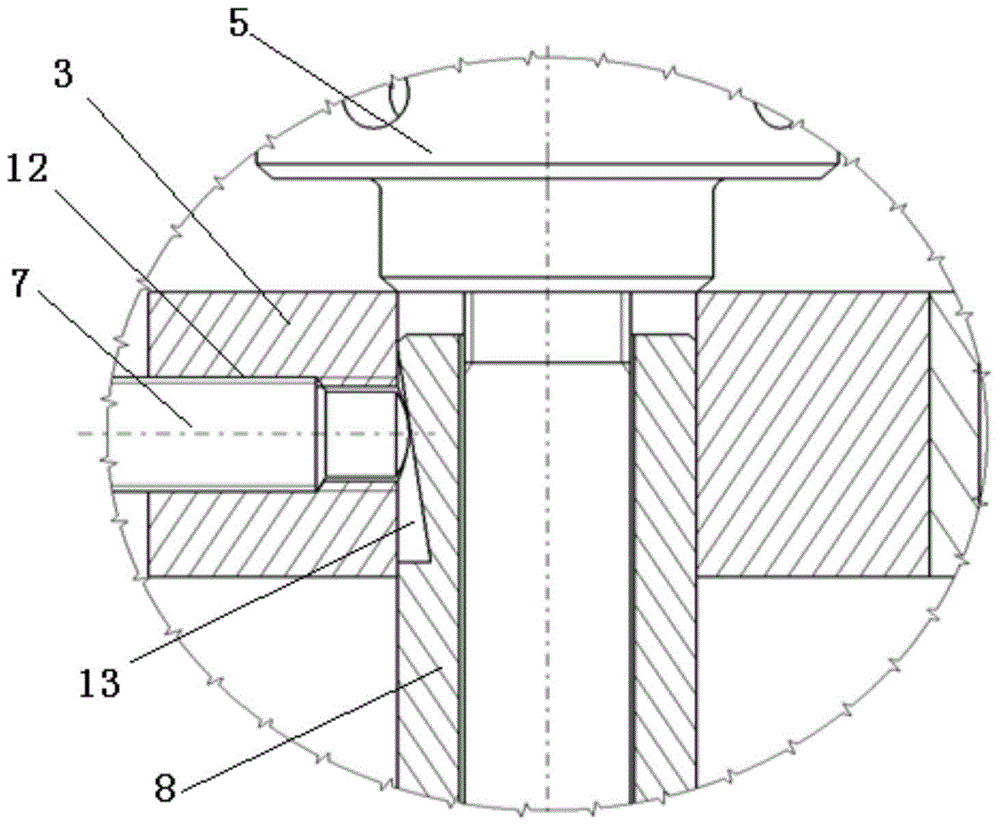

[0012] With reference to the attached drawings, the supporting jig structure for making holes of the double ear piece part includes a jig body and an ear piece holder. The jig body has a horizontal base 1 and a vertical datum 2 on the horizontal base 1. The side of the reference block 2 is provided with a connecting piece for fixing the double ear piece parts 11, and the upper end of the reference block 2 is provided with a flat plate-shaped drilling template 3, which is provided with a drilling film hole 4 and a through hole 6 for connecting the ear pads , There is a compression hole 12 and a compression bolt 7 perpendicular to the through hole on the outer side of the drill template 3. The ear piece holder is a structure composed of a hook bolt 10 and a hook sleeve 8. The upper end of the hook bolt 10 has an external thread and is screwed with the knurled nut 5, and the lower end forms a hook holder. The outer diameter of the hook sleeve 8 matches the through hole on the drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com