Minor radius exchange platform for machine tool

A switch station, small-radius technology, applied in the field of switch stations, can solve problems such as poor reliability, complexity, and affecting the overall layout and appearance of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

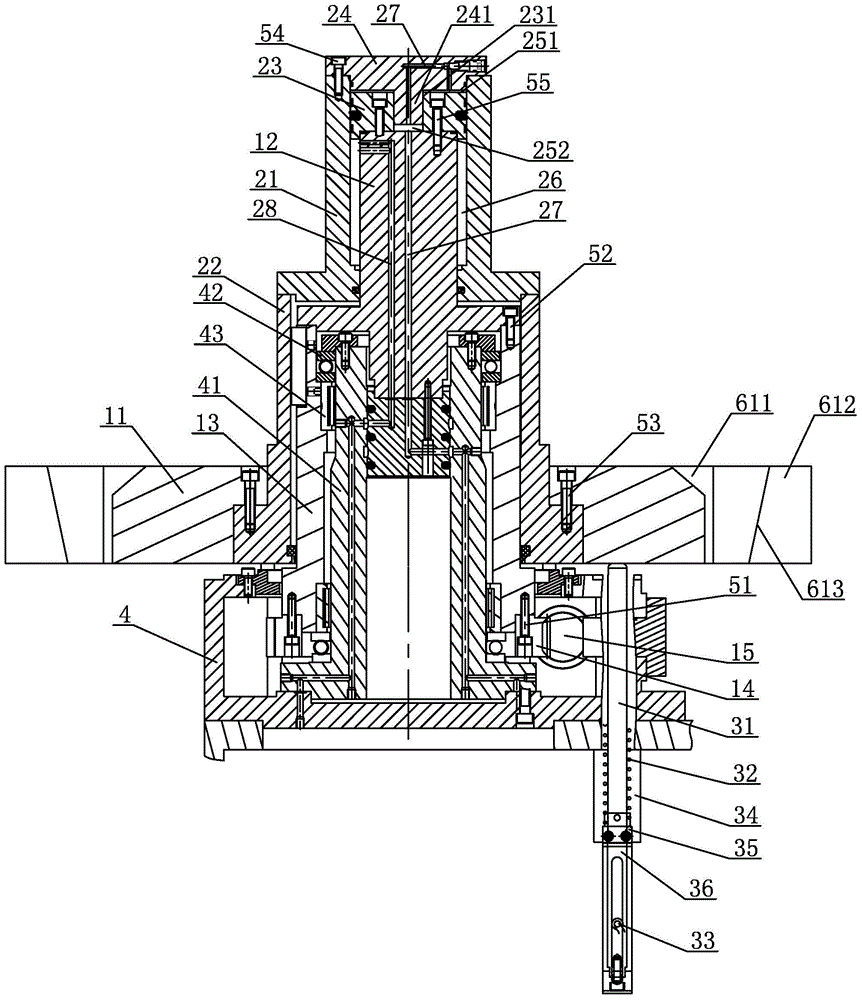

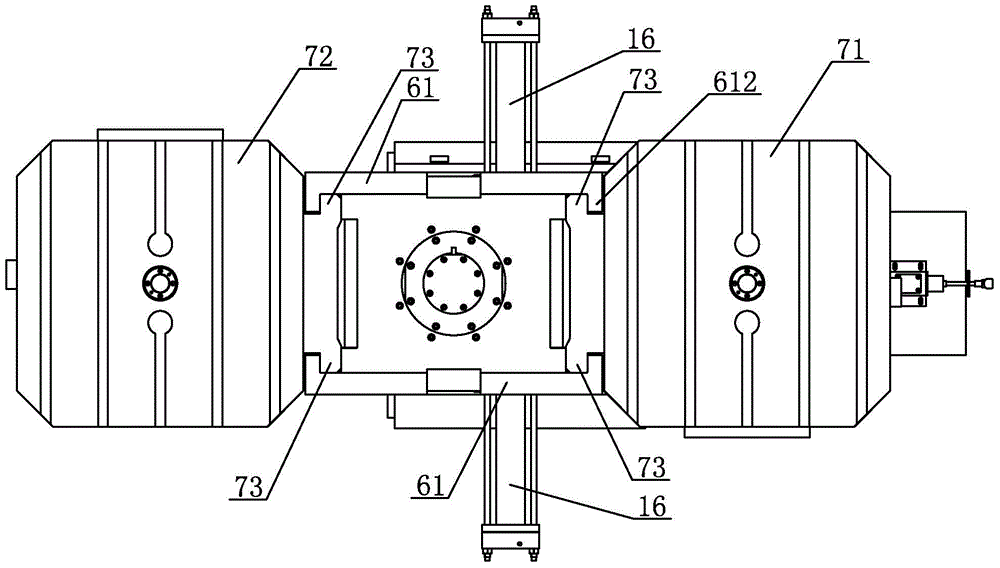

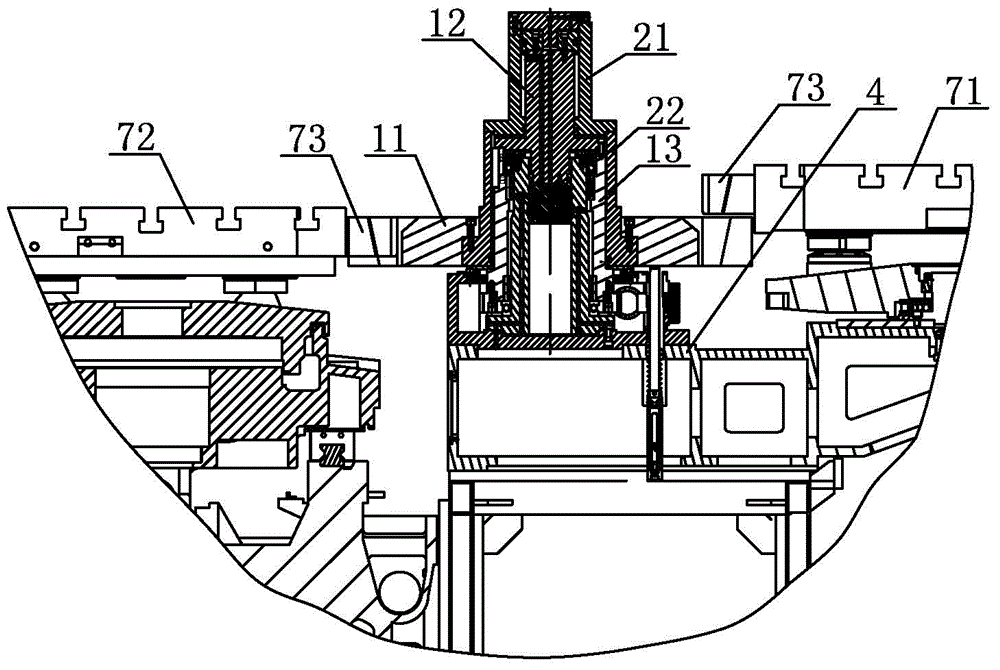

[0014] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0015] As shown in the figure, a small-radius exchange table for a machine tool includes a slewing mechanism, a lifting mechanism and a lifting detection mechanism arranged on the exchange table base 4. A support sleeve 41 is installed on the exchange table base 4. The upper and lower ends of the support sleeve 41 A one-way thrust ball bearing 42 and a needle roller bearing 43 are installed on the outer side.

[0016] The rotary mechanism includes a rotary base 11, a rotary shaft 12, a rotary sleeve 13, a gear 14, a rack 15, and two rotary oil cylinders 16 symmetrically arranged on one side of the rotary shaft 12. The two rotary oil cylinders 16 are connected by the rack 15. The rotating sleeve 13 is sleeved on the outer side of the supporting sleeve 41 and leans on the one-way thrust ball bearing 42, the gear 14 is sleeved on the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com