Multi-station machine tool for machining air intake and exhaust rocker arms of automobile and air intake and exhaust rocker arm machining method thereof

An air intake and exhaust, multi-station technology, used in metal processing machinery parts, metal processing, metal processing equipment and other directions, can solve the problems of high precision requirements, many processes, and the accuracy of parts cannot be guaranteed, and achieves stable and reliable mechanism. The effect of high machining accuracy and positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

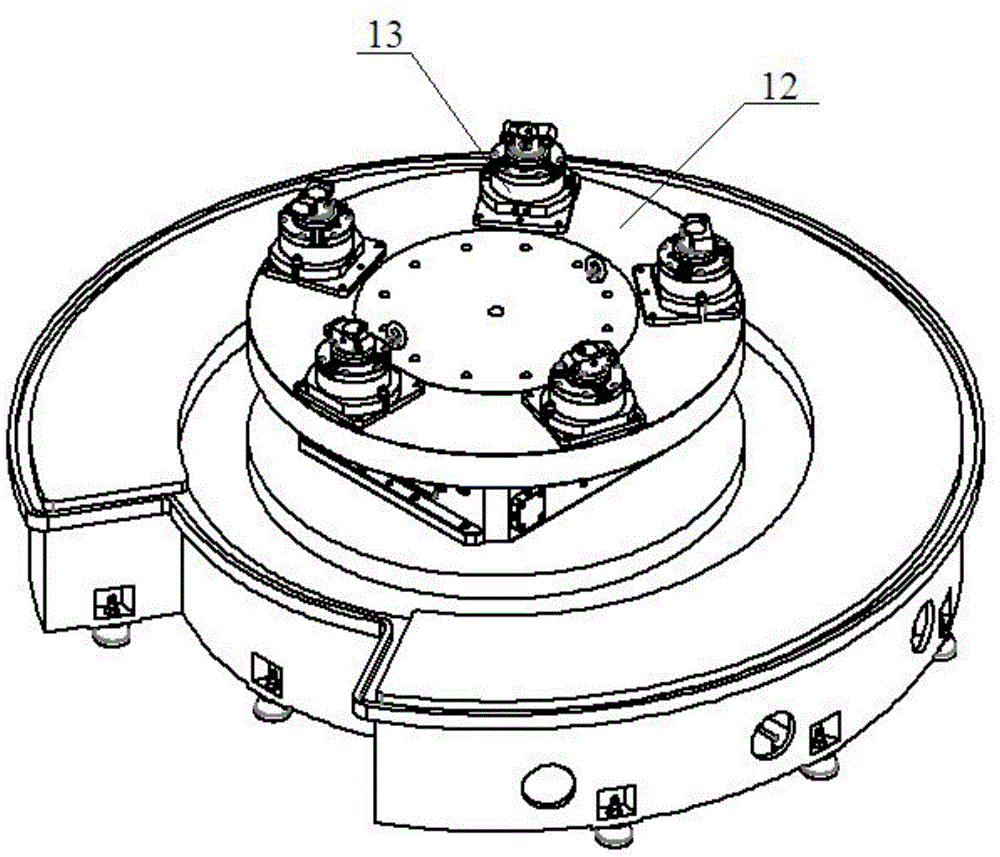

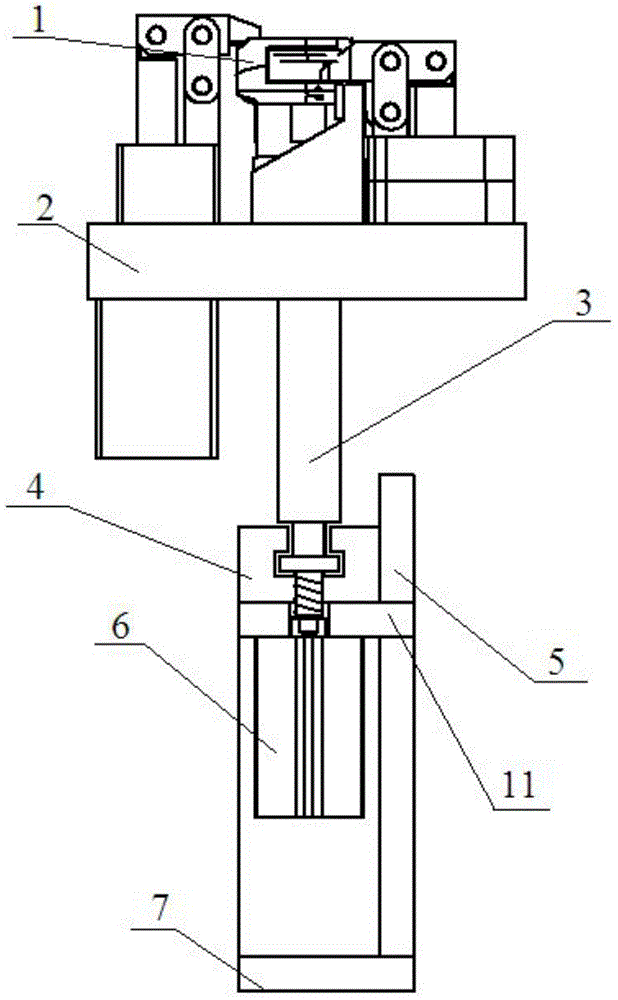

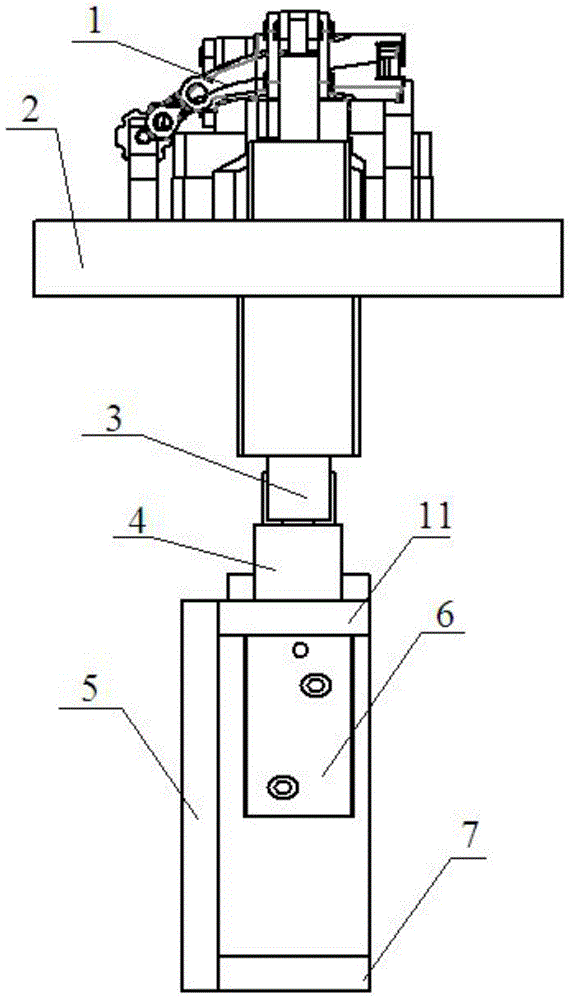

[0040] figure 1 It is a schematic diagram of a multi-station machine tool turntable base for a multi-station machine tool for processing automobile intake and exhaust rocker arms according to the present invention; figure 2 It is a front view of a jig for automatically inserting and pulling out positioning parts of a multi-station machine tool for processing automobile intake and exhaust rocker arms of the present invention; image 3 It is a side view of a fixture for automatically inserting and pulling out positioning parts of a multi-station machine tool for processing automobile intake and exhaust rocker arms according to the present invention; Figure 4 It is a top view of a fixture of a multi-station machine tool for processing the intake and exhaust rocker arms of automobiles in the present invention; as shown in the figure, a multi-station machine tool for processing the intake and exhaust rocker arms of automobiles 1 of the present invention, It includes the workpiec...

Embodiment 2

[0047] The positioning fine-tuning part can adopt auxiliary support oil cylinder, and other parts are identical with embodiment 1.

[0048] By adopting the technical solution of the present invention, the automatic positioning and compacting of the workpiece intake and exhaust rocker 1 can be realized, and preparations are made for the subsequent further improved automatic upper and lower workpiece intake and exhaust rocker 1 materials.

[0049] The method for processing the intake and exhaust rocker arms by using a multi-station machine tool for processing the intake and exhaust rocker arms of automobiles, the steps are as follows:

[0050] (1) The positioning pin rod 3 is inserted into the hole of the workpiece intake and exhaust rocker arm 1, and the manual knob 8 is turned to make the side of the workpiece intake and exhaust rocker arm 1 lean against the positioning block 10; the first compression cylinder 9, the second The compression cylinder 91 and the third compression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com