A hot runner nozzle

A hot runner and hot nozzle technology, applied in the field of hot runner pouring, can solve the problems of reducing production efficiency, burning hot nozzles, fast heat dissipation, etc., and achieving the effect of prolonging service life, improving production efficiency and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

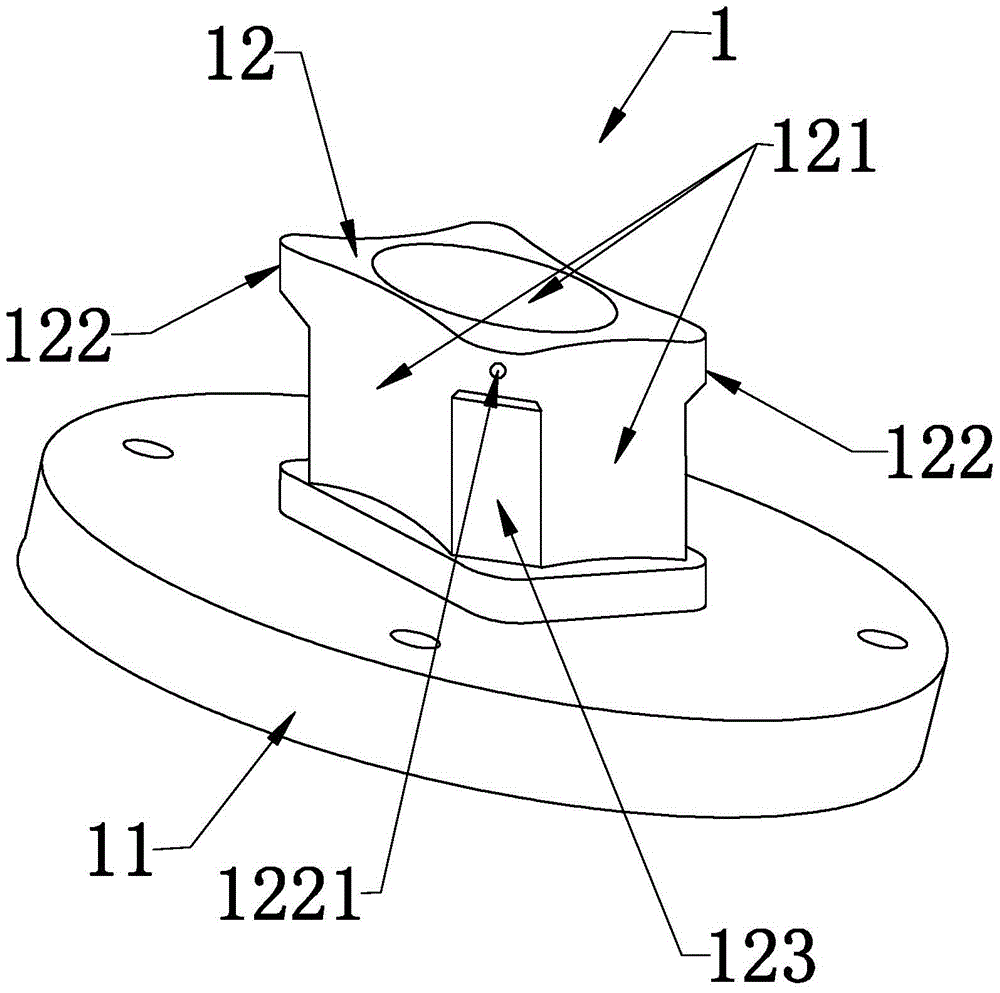

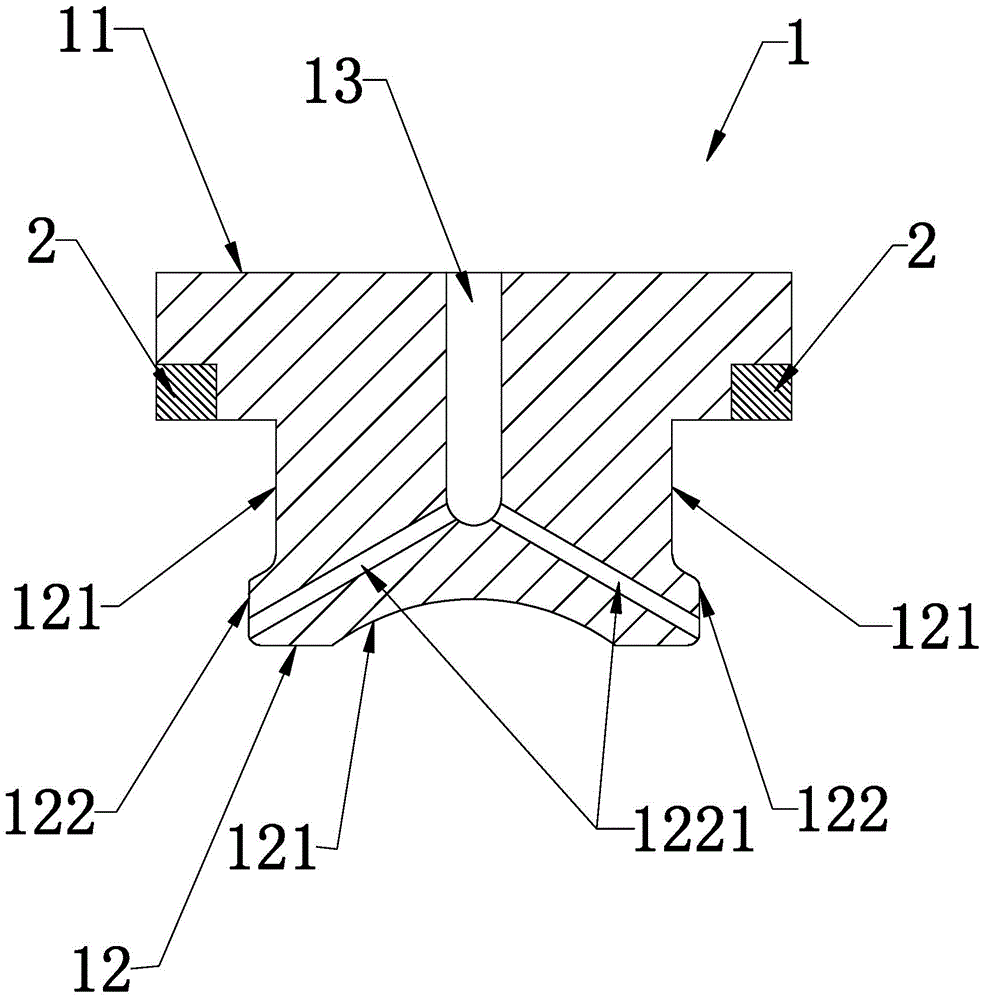

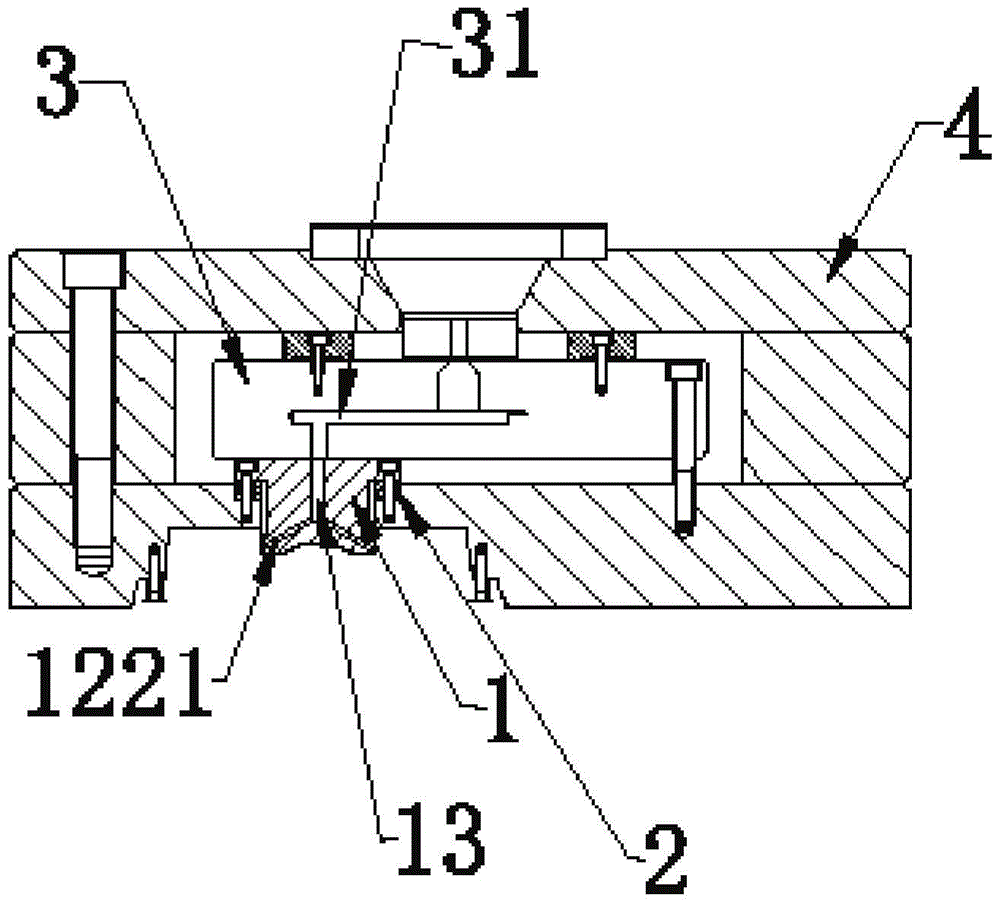

[0015] Such as Figure 1 to Figure 3 As shown, a hot runner hot nozzle, the hot nozzle 1 is a copper hot nozzle, it can be a copper hot nozzle, beryllium copper hot nozzle, bronze hot nozzle and other copper hot nozzles, and this solution uses red copper hot mouth.

[0016] The hot nozzle 1 has an integrated structure and is divided into two parts: the installation end 11 and the glue inlet end 12 . The installation end 11 is a disc shape, which is used for connecting with the heating plate 3 to absorb heat in a large area. The glue inlet 12 is in the shape of a square prism, and concave surfaces 121 are provided on the four sides and the top surface of the glue inlet 12, and a concave platform 123 is provided between adjacent two sides and near the installation end 11. , a corner 122 is formed at a position away from the installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com