A Connected Hydraulic Energy Feed Suspension System

A suspension system and energy feeding technology, which is applied in the field of vehicle engineering, can solve problems such as energy recovery, and achieve the effects of convenient layout, small speed fluctuation, and consistent rotation direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

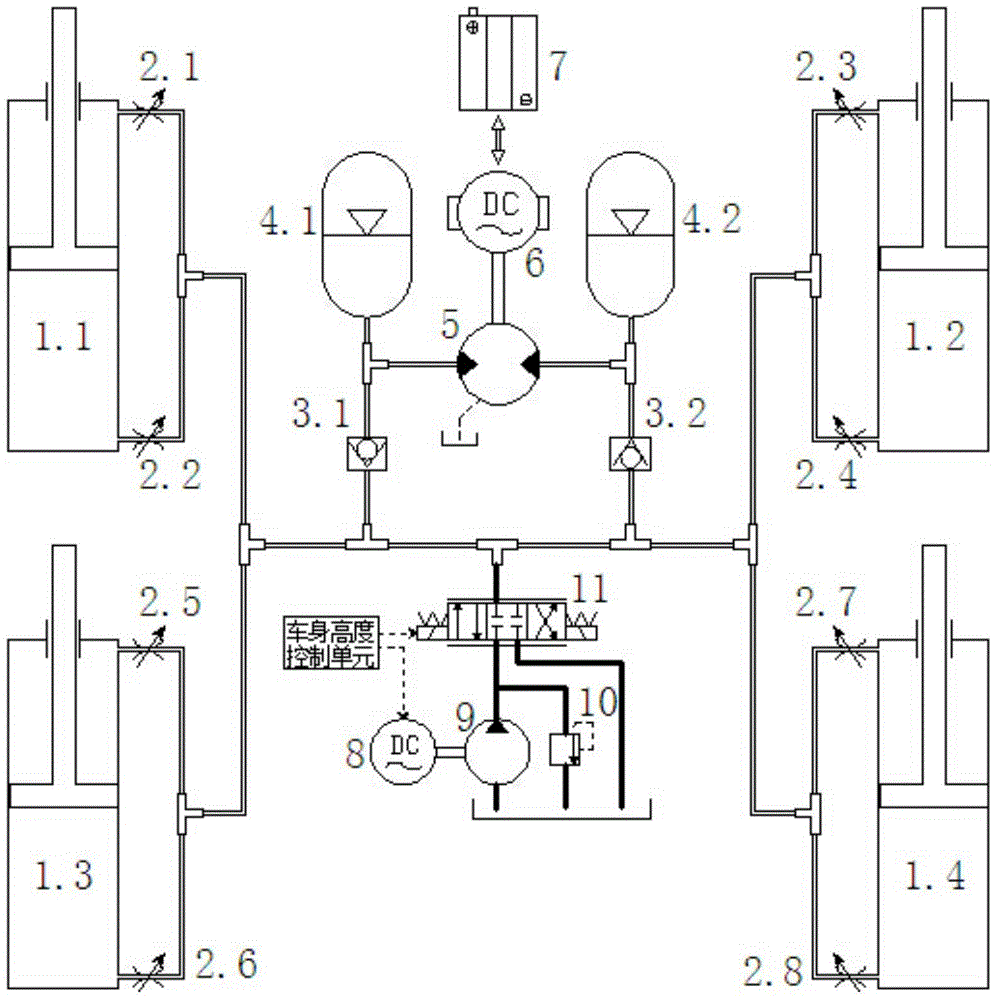

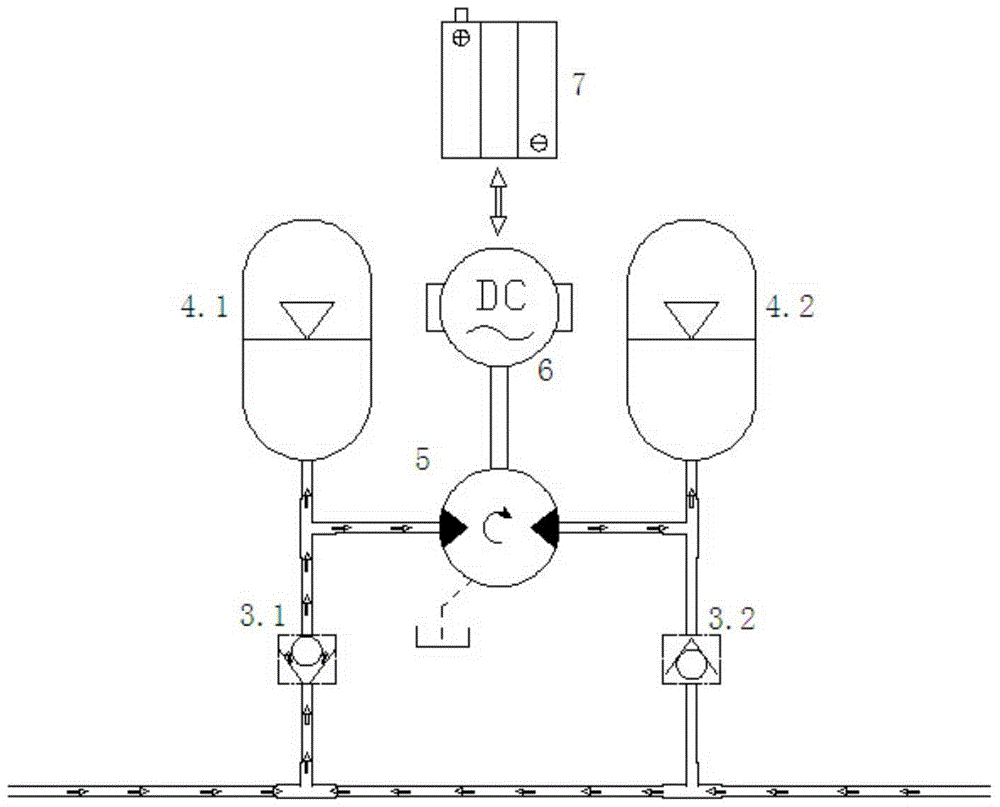

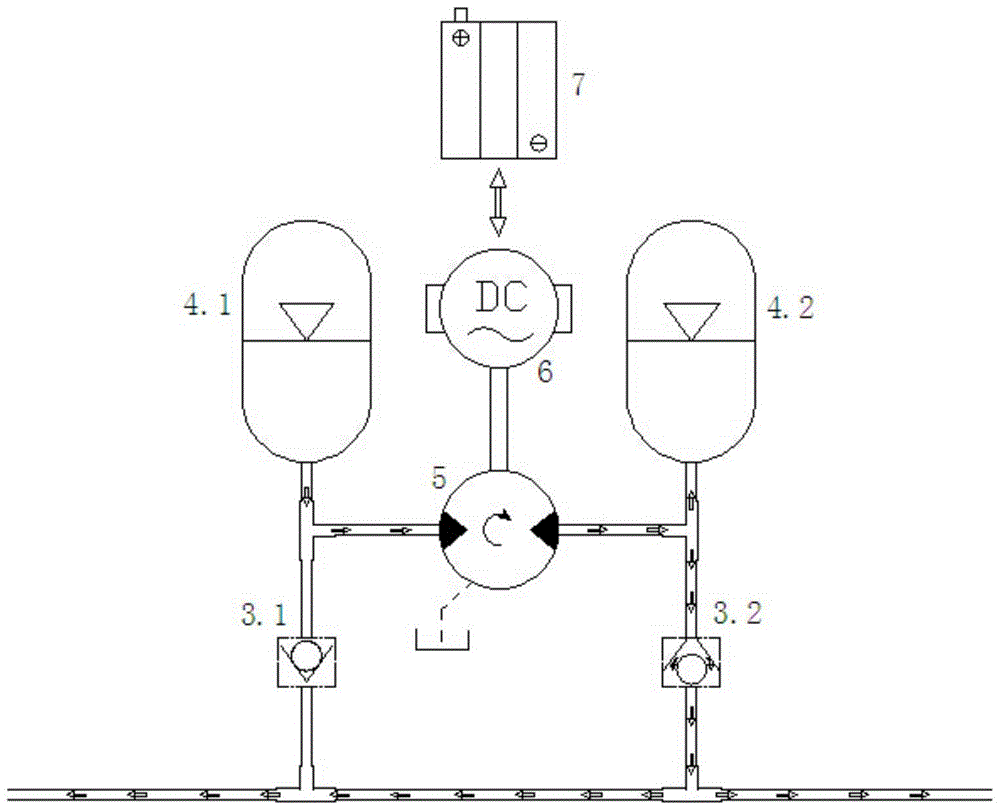

[0028] A fully connected hydraulic energy storage suspension system, such as figure 1 As shown, the oil ports of the rodless cavity and the rod cavity of hydraulic cylinders 1.1, 1.2, 1.3, and 1.4 are all connected through damping valves, oil pipes and three-way joints to form a fully connected hydraulic circuit. The first one-way valve 3.1, the second one-way valve The combination of the valve 3.2 and the first accumulator 4.1 and the second accumulator 4.2 forms a hydraulic rectification circuit, and the hydraulic motor 5 drives the DC generator 6 as an energy recovery unit installed on the first accumulator 4.1 and the second accumulator 4.2 Among them, the oil pump 9, the overflow valve 10 and the proportional solenoid valve 11 form the vehicle height adjustment unit.

[0029] The outlets of the two working chambers of the hydraulic cylinder are respectively connected to an adjustable damping valve, and the adjustable damping valve affects the speed of oil in and out of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com