Buffer device for composite damping force of elevator

A composite damping and buffering device technology, which is applied in the field of the safety system of the box elevator bottoming out, can solve the problems of passenger danger, large spring load, buffering, etc., improve comfort and reliability, increase the reduction of damping force, The effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

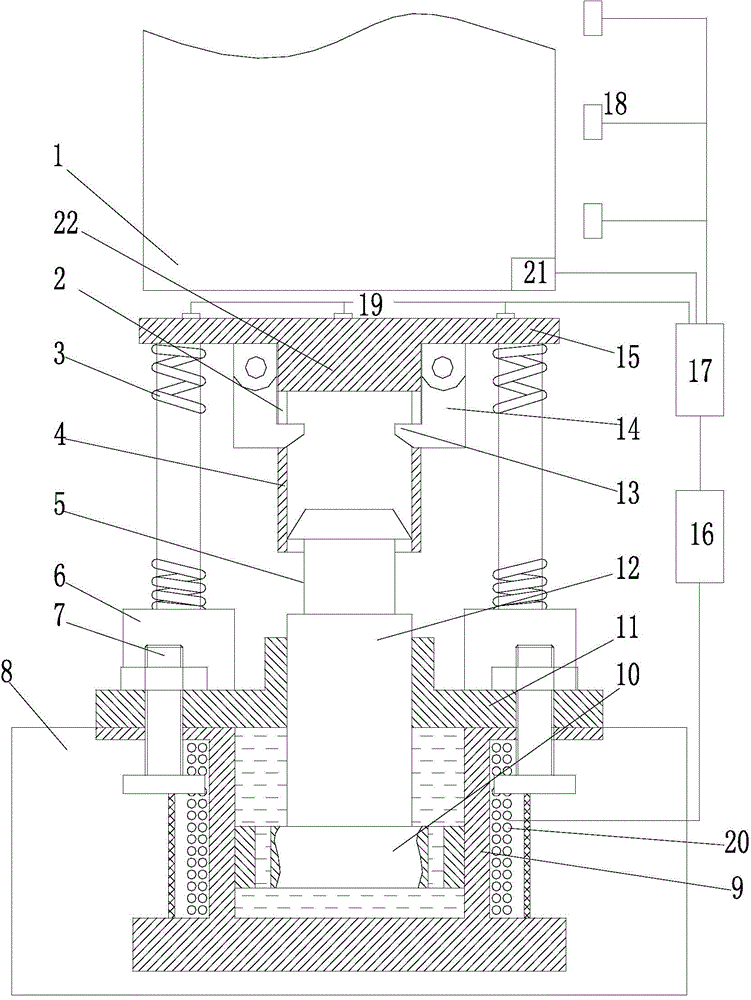

[0032] figure 1 It is a schematic structural diagram of the present invention, as shown in the figure: the elevator composite damping force buffer device of this embodiment includes a buffer component and a magnetorheological damping component;

[0033] The buffer assembly is fixedly arranged at the bottom of the elevator shaft to prevent the elevator car body from bottoming out rigidly;

[0034] The magnetorheological damping assembly includes a magnetorheological damping body and a control system;

[0035] The control system includes:

[0036] The electromagnetic coil 19 is used to provide an electromagnetic field for the magnetorheological damping body;

[0037] The power supply unit 16 is used to provide power for the electromagnetic coil;

[0038] The falling parameter detection unit is used to detect the falling parameters of the elevator car;

[0039] The central processing unit 17 is configured to receive the data signal of the falling parameter detection unit and issue a power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com