Process for remediation of volatile organic pollutants in groundwater

A volatile organic and groundwater technology, applied in the treatment of polluted groundwater/leachate, flotation water/sewage treatment, etc., can solve the problems of rapid decline of pollutant concentration, impact on groundwater flow field, slow release of pollutants, etc. , to achieve good repair effect, fast processing speed, and fast removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

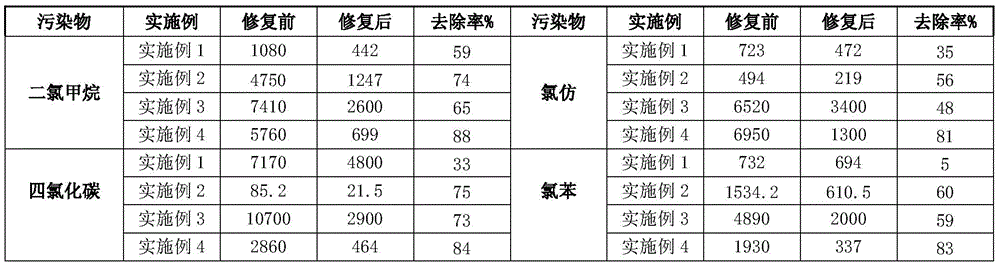

Examples

Embodiment 1

[0029] Processes for remediation of volatile organic pollutants in groundwater:

[0030] (1) Use the extraction well to extract the groundwater polluted by volatile organic pollutants at a certain flow rate and inject it into the surface aeration tank;

[0031] (2) Utilize blower or stripping tower to aerate the polluted water in the aeration tank;

[0032] (3) re-inject the polluted water after aeration into the ground at a certain flow rate through the injection well;

[0033] Wherein, the extraction well is set at the most serious groundwater pollution plume; the injection well is respectively set at the upstream and downstream of the groundwater pollution plume;

[0034] The flow rate in the steps (1) and (3) should be reasonably determined according to the layout of extraction wells and injection wells, so as to reduce the impact on the groundwater flow field as much as possible.

[0035] The aeration requirement in the described step (2) is: the water aeration rate per...

Embodiment 2

[0038] Processes for remediation of volatile organic pollutants in groundwater:

[0039] (1) Use the extraction well to extract the groundwater polluted by volatile organic pollutants at a certain flow rate and inject it into the surface aeration tank;

[0040] (2) Use a blower or a blow-off tower to aerate the polluted water in the aeration tank for a period of time;

[0041] (3) re-inject the polluted water after aeration into the ground at a certain flow rate through the injection well;

[0042] Wherein, the extraction well is set at the most serious groundwater pollution plume; the injection well is respectively set at the upstream and downstream of the groundwater pollution plume;

[0043] The flow rate in the steps (1) and (3) should be reasonably determined according to the layout of extraction wells and injection wells, so as to reduce the impact on the groundwater flow field as much as possible.

[0044] The aeration requirement in the described step (2) is: the wat...

Embodiment 3

[0047] Processes for remediation of volatile organic pollutants in groundwater:

[0048] (1) Use the extraction well to extract the groundwater polluted by volatile organic pollutants at a certain flow rate and inject it into the surface aeration tank;

[0049] (2) Use a blower or a blow-off tower to aerate the polluted water in the aeration tank for a period of time;

[0050] (3) re-inject the polluted water after aeration into the ground at a certain flow rate through the injection well;

[0051] Wherein, the extraction well is set at the most serious groundwater pollution plume; the injection well is respectively set at the upstream and downstream of the groundwater pollution plume;

[0052] The flow rate in the steps (1) and (3) should be reasonably determined according to the layout of extraction wells and injection wells, so as to reduce the impact on the groundwater flow field as much as possible.

[0053] The aeration requirement in the described step (2) is: the aer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com