Honeycomb high-efficiency sinking flow aerobic reactor

An aerobic reactor, honeycomb technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc. To the utilization and other issues, to achieve the effect of simple structure, simplifying the reactor structure, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

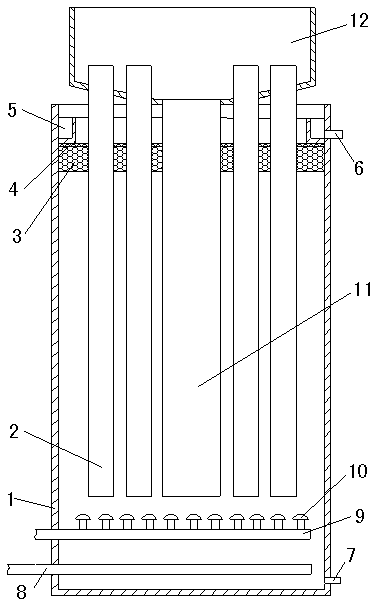

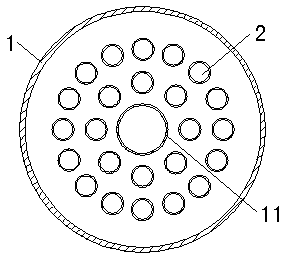

[0017] Such as figure 1 As shown, the honeycomb type high-efficiency sinking flow aerobic reactor of the present invention is columnar, adopts a steel structure, and mainly includes a shell 1, and the shell 1 is provided with an inflow aeration zone, an air lift sinking flow mixing zone and Sediment filtration zone 3. A gas-liquid separation tank 12 is connected to the top of the housing 1 .

[0018] A water distribution pipe 8 and an aeration pipe 9 are arranged in the water inlet aeration area, and aeration heads 10 are distributed on the aeration pipe 9 to form an aeration device, and other aeration devices can also be used. Oxygenates the water body by aeration to carry out the aerobic reaction. The bottom of the housing 1 is provided with a mud discharge pipe 9 below the water distribution pipe 8, and a control valve is provided on the mud discharge pipe 9. When discharging mud, open the control valve on the mud discharge pipe 9 and discharge the casing 1 by self-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com