Sintered brick prepared from wastes and preparation method thereof

A technology for sintered bricks and wastes, which is applied in the field of preparation of waste sintered bricks and waste sintered bricks, can solve the problems of occupying large land and pile up at fixed points, and achieve the effect of strong pressure bearing capacity and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

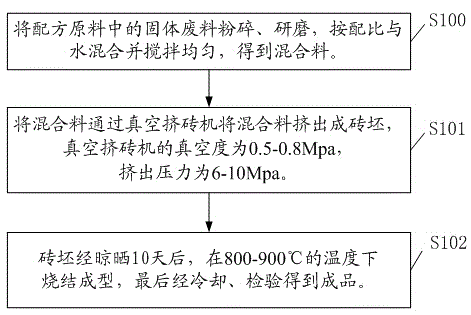

[0036] Such as figure 1 Shown, a kind of preparation method of waste material sintered brick of the present invention comprises the following steps:

[0037] S100 crushes and grinds the solid waste in the formula raw materials, mixes it with water according to the proportion and stirs it evenly to obtain the mixture.

[0038] Wherein, the formula includes raw materials by weight percentage: 92-98% solid waste and 2-8% water; wherein the solid waste includes the following:

[0039] Ceramic waste 25-35%;

[0040] Cement dust 2-5%;

[0041] Cinder 22-30%;

[0043] Construction river silt 10-15%.

[0044] It should be noted that the ceramic waste in the present invention includes ceramic slag and ceramic waste sludge, and the ratio of the ceramic slag to the ceramic waste sludge is 1:0.5-2.5.

[0045] The ceramic waste, coal cinder, coal gangue and construction river silt in the formula raw materials are first pulverized by a pulverizer to reduce ...

Embodiment 1

[0056] According to the percentage by weight, 26% ceramic waste, 3% cement dust, 28% cinder, 24% coal gangue and 12% construction river silt are crushed and ground to a particle size of ≤ 200 mesh, then mixed with 7% water and stirred evenly to obtain a mixed material;

[0057] The mixture is extruded into bricks through a vacuum brick extruder, the vacuum of the vacuum brick extruder is 0.5Mpa, and the extrusion pressure is 6Mpa;

[0058] After drying for 10 days, the adobe is sintered at 850°C for 27 hours to form it, and finally it is cooled and inspected to obtain the finished product.

Embodiment 2

[0060]According to the percentage by weight, 28% ceramic waste, 4% cement dust, 25% cinder, 29% coal gangue and 10% construction river silt are crushed and ground to a particle size of ≤200 mesh, then mixed with 4% water and stirred evenly to obtain a mixed material;

[0061] Extrude the mixture into adobe through a vacuum brick extruder, the vacuum degree of the vacuum brick extruder is 0.6Mpa, and the extrusion pressure is 7Mpa;

[0062] After drying for 10 days, the adobe is sintered at 880°C for 25 hours to form it, and finally it is cooled and inspected to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com