Preparation method of laminarin with anti-tumor activity

An anti-tumor activity, laminarin technology, applied in the field of kelp polysaccharide, can solve the problems of restricting the deep processing and application of kelp polysaccharide, less research, etc., and achieve the effects of avoiding the decrease of laminarin content, high protein removal rate, and avoiding changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

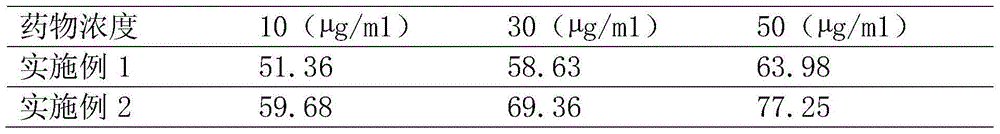

Examples

Embodiment 1

[0022] A preparation method of laminarin with antitumor activity, comprising the steps of:

[0023] 1) Raw material processing: 10 kg of dried sea-tangle is pulverized;

[0024] 2) Ultra-high pressure treatment: add 400kg of pure water to the pulverized kelp, pressure 350MPa, temperature 85°C, ultra-high pressure treatment for 4 minutes, filter after completion, and collect the filtrate;

[0025] 3) Ultrasonic treatment: The filtrate obtained in step 2) was ultrasonically treated for 10 minutes at an operating temperature of 85°C and a power of 300W. After completion, filter and collect the filtrate;

[0026] 4) Removal of alginate: adjust the pH value of the filtrate obtained in step 3) to 1.2 with a hydrochloric acid solution with a concentration of 1.5M, centrifuge at a speed of 12000r / min for 20min, and collect the supernatant;

[0027] 5) Decolorization: Add 95% ethanol with a mass concentration equivalent to 2 times the weight of the supernatant to the supernatant obtai...

Embodiment 2

[0030] 1) Raw material processing: crush 10kg of fresh kelp;

[0031] 2) Ultra-high pressure treatment: add 600kg of pure water to the crushed kelp, pressure 350MPa, action temperature 80°C, ultra-high pressure treatment for 2min, filter after completion, and collect the filtrate;

[0032] 3) Ultrasonic treatment: The filtrate obtained in step 2) was ultrasonically treated for 8 minutes at an operating temperature of 80°C and a power of 300W. After completion, filter and collect the filtrate;

[0033] 4) Removal of alginate: adjust the pH value of the filtrate obtained in step 3) to 1.2 with a hydrochloric acid solution with a concentration of 1.5M, centrifuge at a speed of 12000r / min for 20min, and collect the supernatant;

[0034] 5) Decolorization: Add 95% ethanol with a mass concentration equivalent to 2 times the weight of the supernatant to the supernatant obtained in step 4), let stand at 4°C for 4 hours, filter, and add 0.5% of the weight of the supernatant to the supe...

Embodiment 3

[0037] 1) Raw material processing: 10 kg of dried sea-tangle is pulverized;

[0038] 2) Ultra-high pressure treatment: Add 500kg of pure water to the pulverized kelp, pressure 350MPa, temperature 70°C, ultra-high pressure treatment for 5 minutes, filter after completion, and collect the filtrate;

[0039] 3) Ultrasonic treatment: process the filtrate obtained in step 2) for 5 minutes with ultrasonic treatment at a temperature of 70° C. and a power of 300 W. After completion, filter and collect the filtrate;

[0040] 4) Removal of alginate: adjust the pH value of the filtrate obtained in step 3) to 1.2 with a hydrochloric acid solution with a concentration of 1.5M, centrifuge at a speed of 12000r / min for 20min, and collect the supernatant;

[0041] 5) Decolorization: Add 95% ethanol with a mass concentration equivalent to 2 times the weight of the supernatant to the supernatant obtained in step 4), let stand at 4°C for 4 hours, filter, and add 0.5% of the weight of the supernat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com