Method and container for preparing biological carbon

A bio-carbon and container technology, which is used in bio-fuels, special forms of dry distillation, petroleum industry, etc., can solve the problems of long firing time, complicated equipment, and complicated steps, and achieve low equipment cost, simple operation and high combustion value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The method of the present invention includes the following steps:

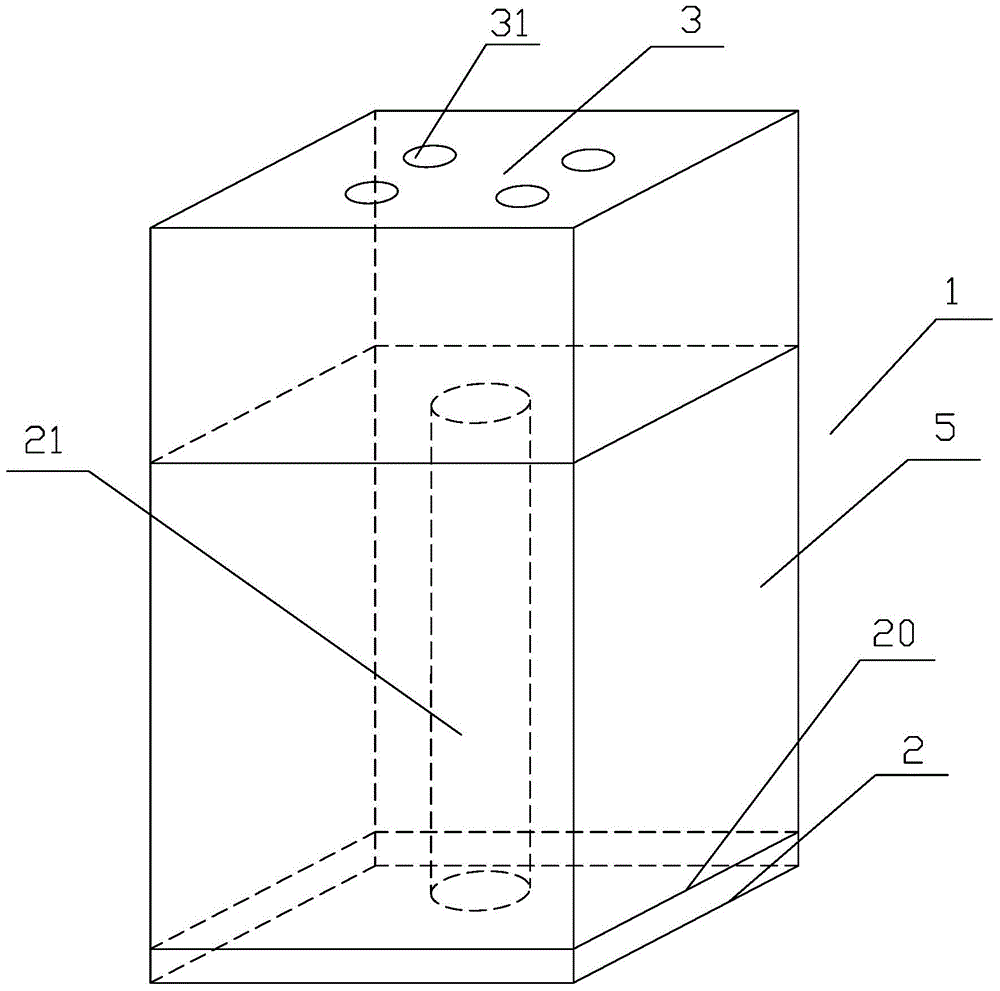

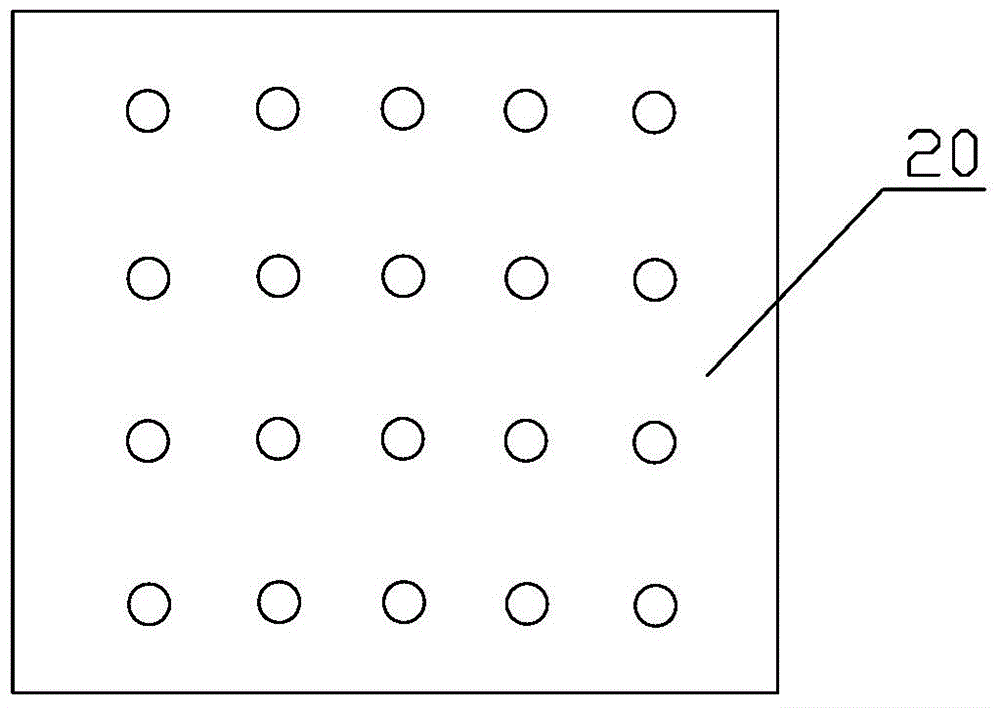

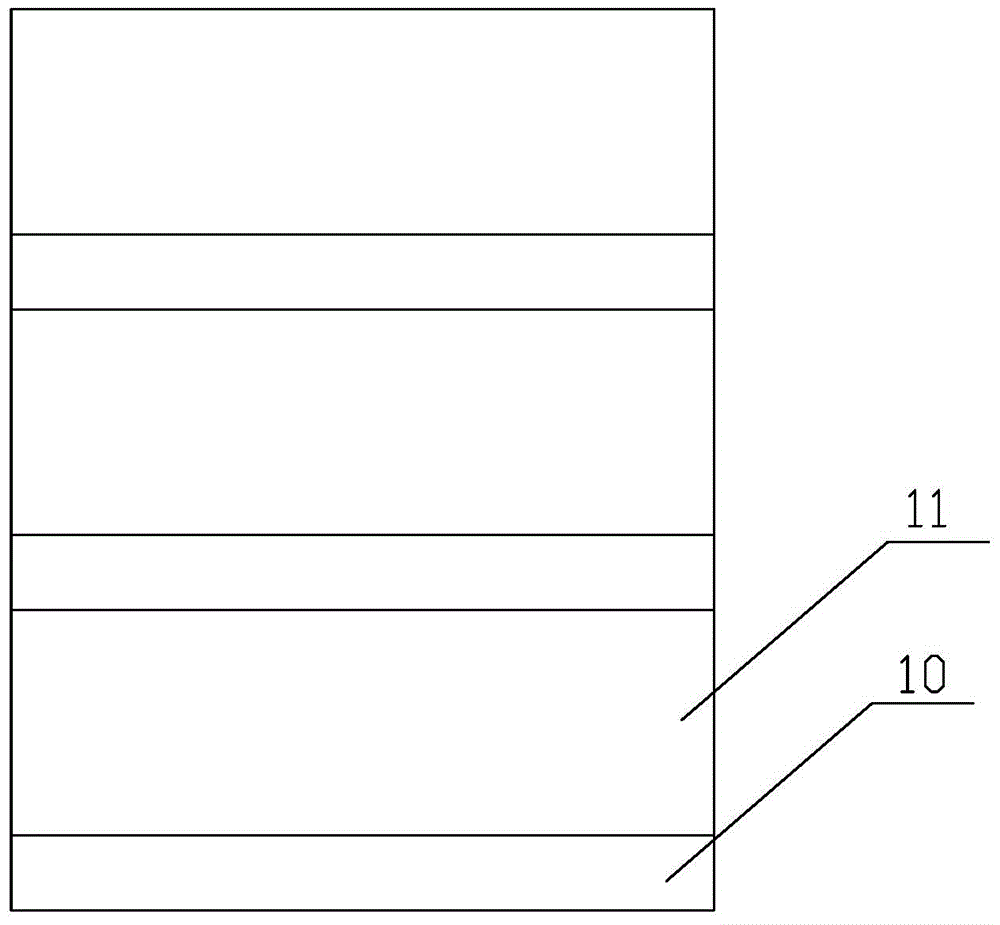

[0025] (1) Lay the carbon 10 on the bottom 2 of the container 1. The carbon of the present invention includes a series of carbon materials such as activated carbon, biochar, charcoal, barbecue carbon, etc. The best form is block or granular, and biochar and activated carbon are the best. Good; the container 1 has an upper opening, and the bottom carbon 10 is laid with food waste 11, and then the layer of food waste 11 is laid with carbon 10, and so on, and finally with the container mouth to maintain one-third of the height of the container 1 Seal the mouth of the container at a distance of one;

[0026] (2) The most important step of the patented method is firing. There are several firing methods:

[0027] 1. After the carbon and kitchen waste are mixed, they can be burned directly, that is, the container, together with the carbon and kitchen waste in the container, are sealed and anaerobic fired. The contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com