Needle driving mechanism for variable space embroidery machine

A driving mechanism and embroidery machine technology, which is applied to the mechanism of embroidery machines, embroidery machines, mechanical equipment, etc., can solve the problems of strict restrictions on the scope of use, difficulty in replacement, and difficulty in installing power shafts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

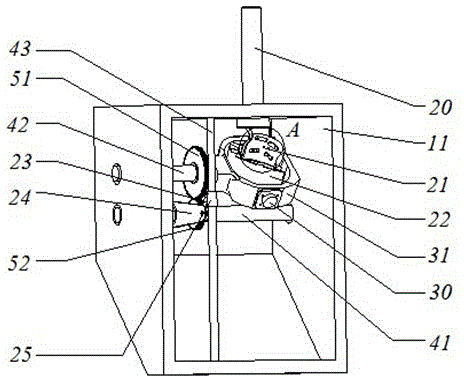

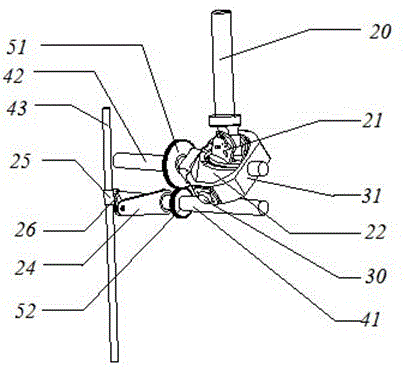

[0021] Such as Figure 1-8 As shown, the needle driving mechanism of the displacement space embroidery machine of the present invention mainly includes a box body 11, a driving mechanism, and a power output part. The shape of the box body 11 is a right-angled trapezoid, and the driving mechanism mainly includes two parts: a displacement space mechanism and a gear mechanism. The power output part is mainly realized through the rotation of the pinion shaft 41, which drives the swing arm 24 to swing up and down to push the needle drive slider 25 to slide up and down.

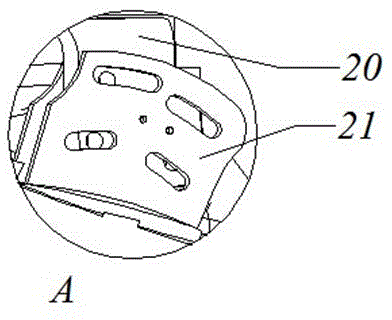

[0022] The displacement space mechanism is composed of a main shaft 20, an elbow 21, a bearing 27, an annular swing shaft 22, and a swing ring 31. The end of the main shaft 20 is flat and has a fixing hole on it, which can cooperate with the adjustment ring on the elbow 21 for adjustment and installation. angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com