Hydraulic system capable of lowering hydraulic oil source startup frequency of AMT (Automated Mechanical Transmission)

A hydraulic system and hydraulic oil source technology, applied in the field of hydraulic systems, can solve the problems of accumulator pressure reduction, affecting the life of solenoid valves, poor sealing performance, etc., and achieve the effect of improving reliability, increasing service life and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

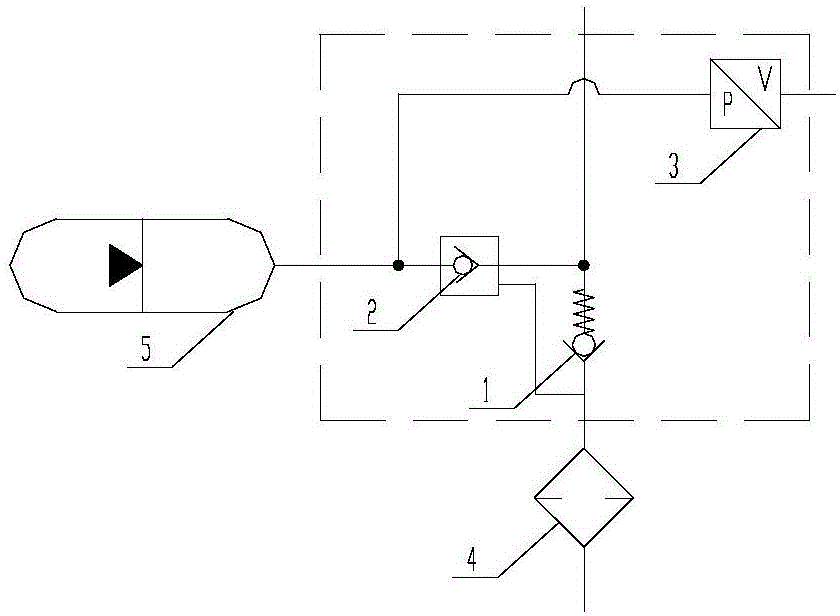

[0022] figure 1 The hydraulic system provided by the present invention is inside the dotted line box: the hydraulic system includes three parts: check valve, hydraulic control check valve and pressure sensor. The oil supplied by the hydraulic oil source enters the system of the present invention before entering the accumulator through the oil filter. The oil circuit entering the system is divided into two routes, one is connected with the control port of the hydraulic control check valve, and the other is connected with the inlet of the check valve. , The one-way sending outlet is divided into two ways, one way is connected with the oil inlet of the hydraulic control one-way valve, and the other way is connected to the original system and each control valve. The oil outlet of the hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com