Internal Combustion Engine Oil Pump

A technology for oil pumps and internal combustion engines, which is applied to lubricating pumps, mechanical equipment, engine components, etc. It can solve the problems of unsatisfactory sealing methods, shorten the service life of internal combustion engines, and reduce the quality of lubrication, so as to ensure smooth transportation and lubrication quality, and avoid engine oil Insufficient pressure, avoiding the effect of oil foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

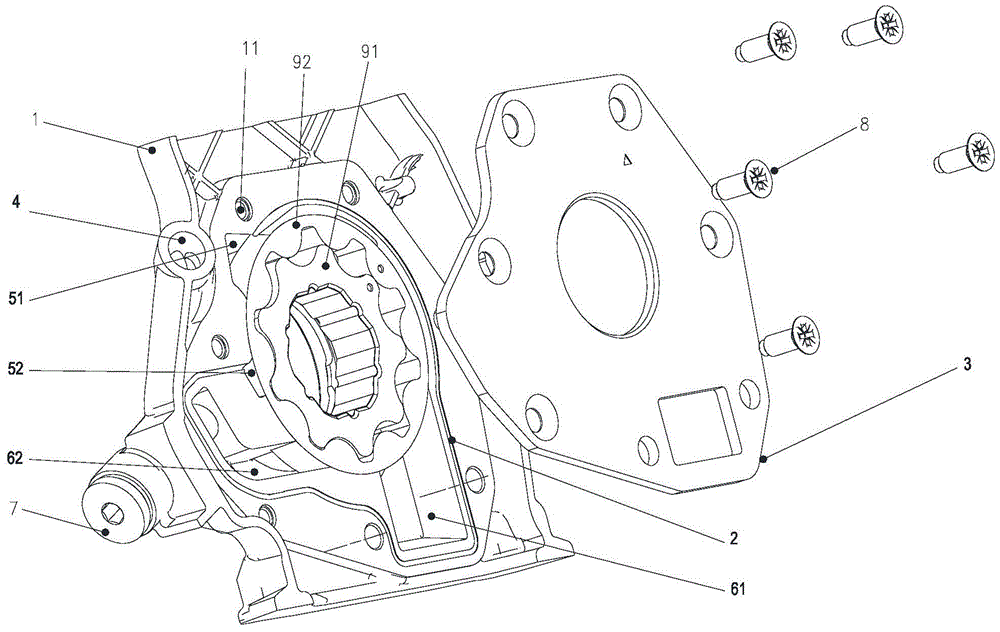

[0018] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the internal combustion engine oil pump of this embodiment includes a pump casing 1 provided with an oil inlet chamber, and the pump casing 1 is also provided with a sealing groove for sealing the oil inlet chamber 2. The internal combustion engine oil pump also includes a pump cover 3 that is detachably connected to the pump casing 1, and the pump cover 3 presses and seals the sealing groove 2; the sealing groove 2 is preferably formed by casting; the pump casing 1 There is a sealing groove 2 specially used to seal the oil inlet cavity. The sealing groove 2 can effectively prevent air from being sucked into the oil cavity through oil seals, water seals or sealing rings, so as to avoid insufficient oil pressure and oil foaming. Ensure the smooth delivery and lubricating quality of engine oil, so that the overall performance of the internal combustion engine can be strengthene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com