Medium-caliber cannonball automatic disassembly production line

A production line and artillery shell technology, applied in the field of automatic dismantling production lines for medium-caliber artillery shells, can solve the problems of high labor intensity, low dismantling efficiency, no use of shells and inventory value, etc., so as to reduce labor intensity, improve production efficiency, and reduce personnel. The effect of the probability of casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

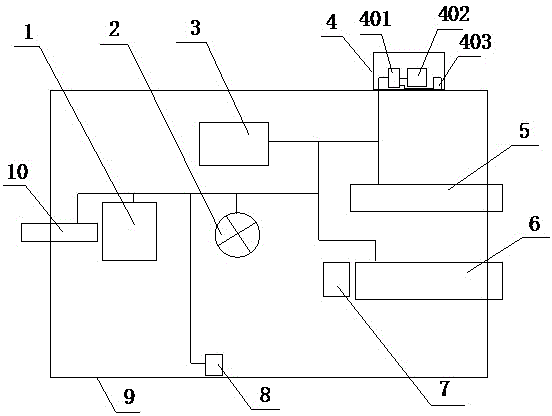

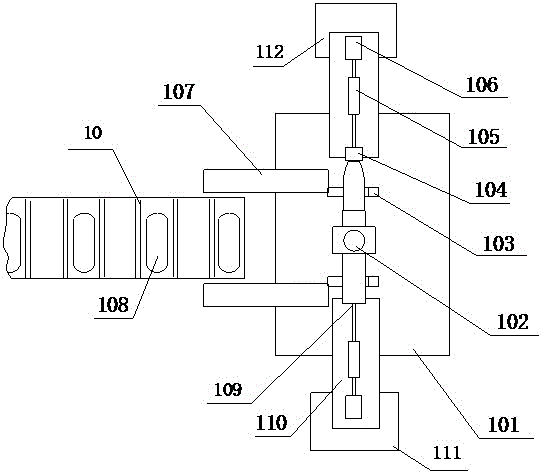

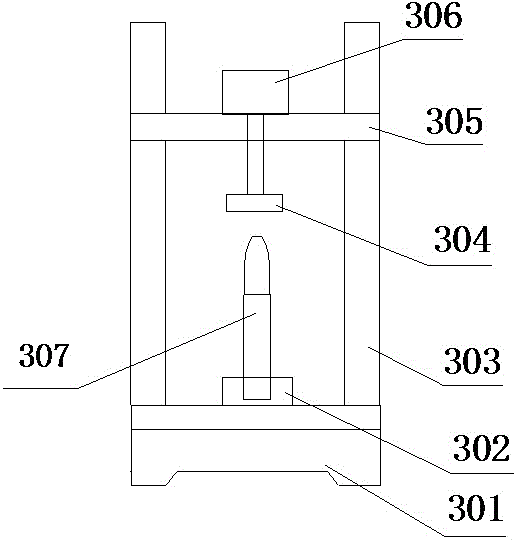

[0023] Such as figure 1 , 2 , 3, and 4, the automatic dismantling production line of medium-caliber shells of the present invention includes a transmission system, a handling manipulator 2, a fully automatic fuze primer spinner 1, a fully automatic bomb pulling machine 3 and an automatic control system, and the transmission system It includes a shell conveyor belt 10 connected to the fully automatic fuze primer unloading machine 1, a cartridge conveyor belt 6 connected to the full-automatic bomb pulling machine 3, and a projectile conveyor belt 5. The shell conveyor belt 10 adopts a chain plate conveyor, and its chain plate Grooves 108 are arranged at equal distances for placing shells, and the bombs are delivered in the same rhythm as the fully automatic fuze primer rotary unloader 1 . The handling manipulator 2 is located in the middle of the fully automatic fuze primer unloading machine 1, the fully automatic bomb puller 3, the cartridge conveyor belt 6 and the project...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com