Method for measuring air specific heat ratio by piston vibration in single-ended sealed horizontal cylinder

A technology of horizontal cylinder and specific heat capacity ratio, applied in the direction of analyzing materials, instruments, etc., can solve problems such as difficulty in realization, rotation uncertainty, uneven surface, etc., and achieve the effect of low cost, easy observation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

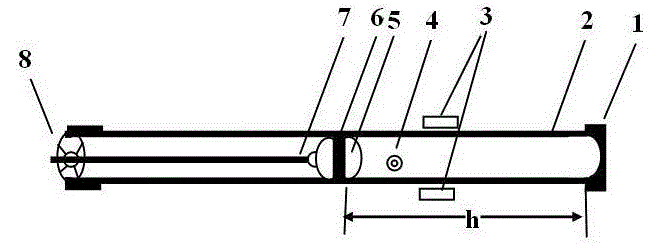

[0013] A cylinder 2 is made of hard transparent materials, such as transparent glass, transparent hard plastic, etc., which can withstand pressure and have relatively small (negligible) deformation caused by pressure; one end of the cylinder 2 passes through The threads and sealing gaskets are connected with the sealing cap 1, and the realization of the sealing connection between the threads and the sealing gaskets is a prior art, which will not be repeated here; the other end of the cylinder 2 is covered with a grid cap 8, which is formed by a grid The flat plate is composed of a rubber cylinder. The grid plate has a central hole and an edge round hole. The two holes are connected by a long strip of solid parts. The edge round hole is connected to the rubber cylinder. The rubber cylinder is made of rubber. The elasticity of muscle is enclosed within the other end of cylinder 2. The outer surface of cylinder 2 has a millimeter scale along the length direction.

[0014] There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com