A method and device for testing the properties of modified raw lacquer pigments

A technology of raw lacquer and pigment, applied in the field of testing the properties of modified raw lacquer and pigment, can solve the problems of difficult mass industrial spraying, high viscosity and long production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

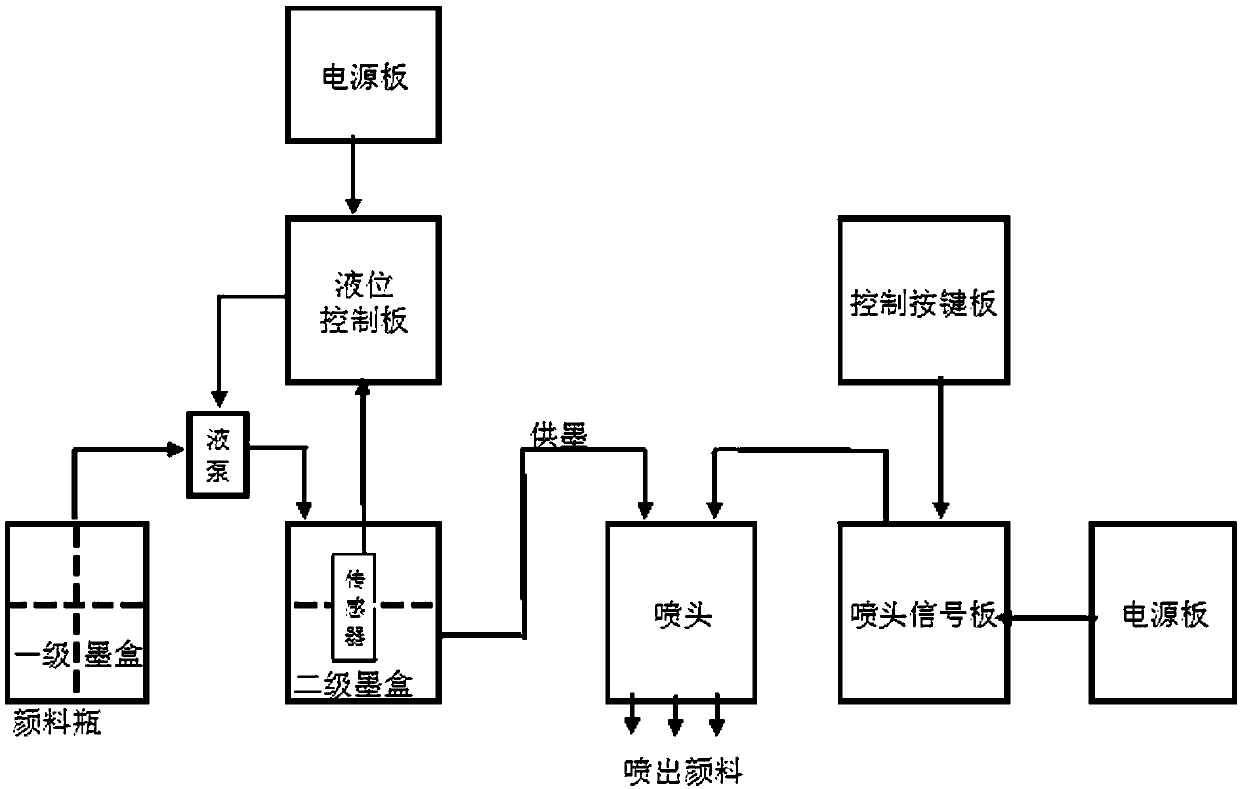

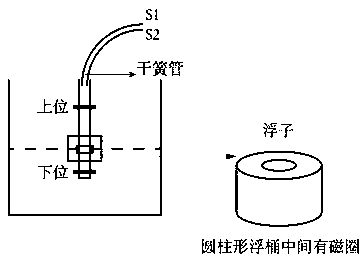

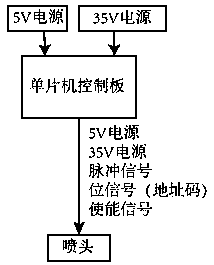

[0020] Control attached figure 1 , the device for testing the performance of modified lacquer pigments, its structure includes a primary ink cartridge, a liquid pump, a secondary ink cartridge, a sensor, a liquid level control board, a nozzle, a nozzle signal board, a control key board, A power board, B power board; one of them The primary ink cartridge is connected to the secondary ink cartridge through the liquid pump, the secondary ink cartridge is connected to the nozzle for ink supply, the signal output terminal of the sensor in the secondary ink cartridge is connected to the signal input terminal of the liquid level control board, and the signal output terminal of the liquid level control board is connected to the signal of the liquid pump Input terminal, the power input terminal of the liquid level control board is connected to the power output terminal of the A power supply board. When the ink pump is working, the secondary ink cartridge supplies ink to the nozzle; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com