Traceability system capable of controlling printing through PLC (Programmable Logic Controller)

A traceability system and printing control technology, applied in the field of traceability system, can solve the problems of low production efficiency, high procurement cost, complicated operation, etc., and achieve the effect of high work efficiency, strong anti-interference, and stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

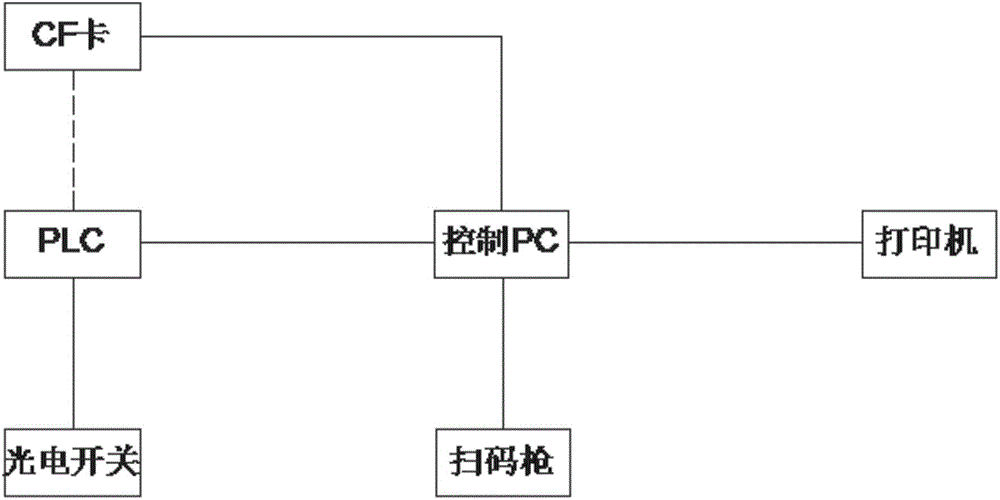

[0016] A traceability system that controls printing by PLC, such as figure 1 As shown, it includes a printer, a control PC, a code scanning gun, a memory card, a photoelectric switch, and a PLC system composed of a CPU module, a serial communication module, a data recording module, an input module, and an output module; the serial communication module and the control PC connection; the data recording module is connected to the memory card; the printer and the code scanning gun are respectively connected to the control PC; the photoelectric switch is set near the label printing end of the printer.

[0017] It should be noted that in the above-mentioned composition of this traceability system, the control PC can be a commercially available ordinary computer, the printer is preferably a Sato GT412e model label printer, the code scanning gun is Denso GT10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com