An activated carbon dosing device and method

A technology of activated carbon and adding devices, applied in chemical instruments and methods, mixers, dissolving, etc., can solve the problems of large gas resistance, impracticality, and high operating costs of filter bags, and achieve simple operation, low manufacturing cost, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

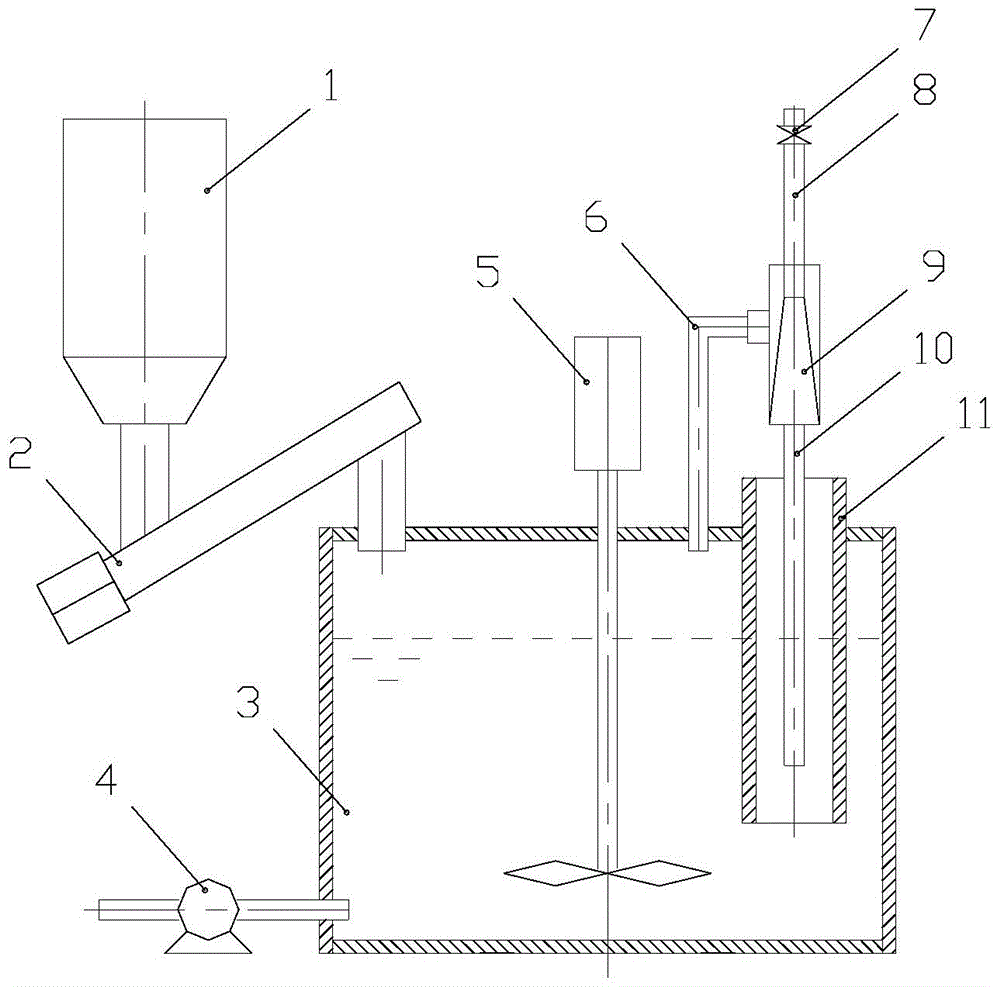

[0027] as attached figure 1 Shown, a kind of activated carbon dosing device, it packs the charcoal slurry tank 3 with exhaust pipe 6, jet pump 8 and gas-liquid separator 11, and the suction port of jet pump is communicated with charcoal slurry tank 3 through exhaust tube 6, and the jet flow The pump outlet pipe 9 is inserted into the gas-liquid separator 11, and the gas-liquid separator 11 is fixed on the carbon slurry tank 3, and the bottom of the gas-liquid separator 11 is located below the liquid level in the carbon slurry tank 3, and the gas-liquid separator 11 The top is positioned on the carbon slurry tank 3 top covers.

[0028] The working process of this embodiment is:

[0029] When the liquid level in the carbon slurry tank 3 reaches a certain position and needs to be fed, the conveyor 3 and the water inlet valve 7 are opened at the same time, and the carbon powder is transported to the carbon slurry tank 3 after being metered by the silo 1 through the screw conveyor...

Embodiment 2

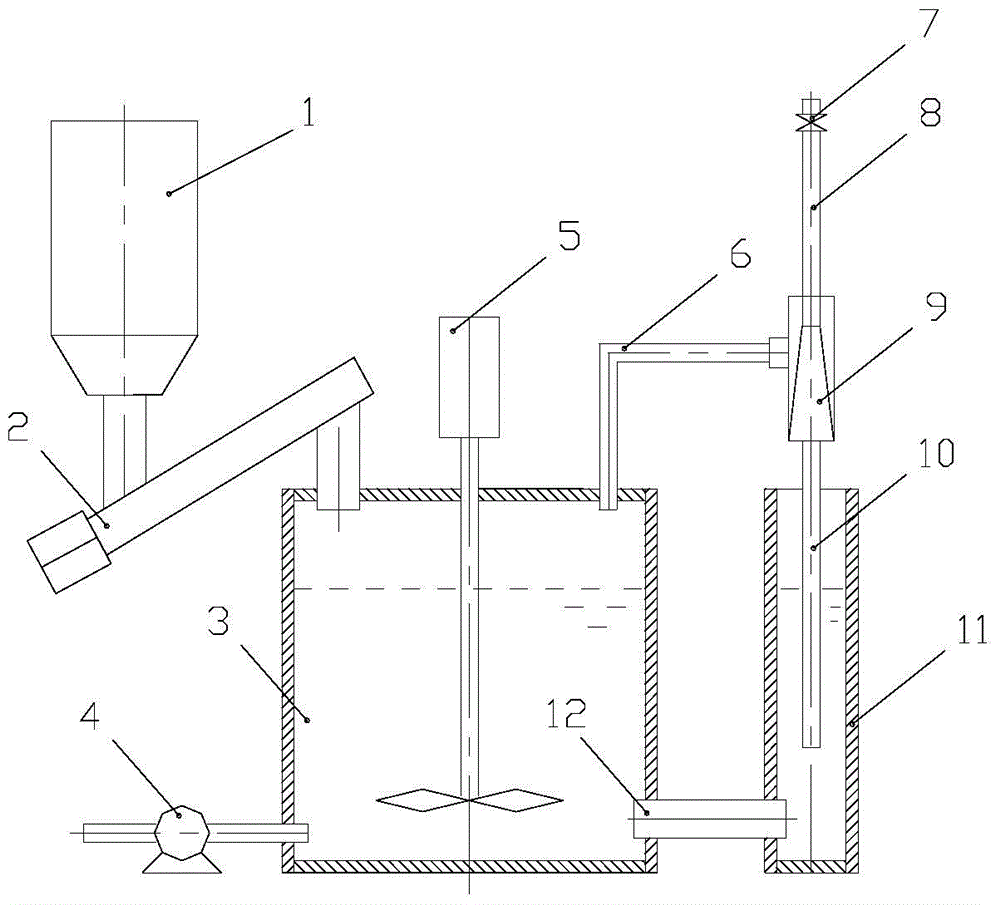

[0033] as attached figure 2 As shown, this embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, the gas-liquid separator 11 is located outside the carbon slurry tank 3, and the gas-liquid separator 11 communicates with the carbon slurry tank 3 through a communication pipe 12 .

[0034] The working process of this embodiment is: when the liquid level in the carbon slurry tank 3 reaches a certain position and needs to be fed, the conveyor 3 and the water inlet valve 7 are opened at the same time, and the carbon powder is transported by the screw conveyor 3 after being measured by the silo 1 To the carbon slurry tank 3, the clean water enters the carbon slurry tank 3 through the water inlet valve 7 and the water inlet pipe 8 through the jet pump 9 and the gas-liquid separator 11 in turn. When the clean water flows through the jet pump 9, a jet suction is formed inside the jet pump 9 Function, the air containing suspended carbon powder par...

Embodiment 3

[0037] as attached figure 1 As shown in or 2, this embodiment is basically the same as Embodiment 1 or 2, the difference is that in this embodiment, the gas-liquid separator 11 has packing inside, which can play a role in stably discharging the airflow and further cleaning the air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com