Movable self-pressure type straightening machine

A straightening machine and straightening technology, which is applied in the field of auto parts processing machinery, can solve problems such as unfavorable production operations, heavy workbench, and immobile head frame, etc., and achieve the effect of simple structure and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings.

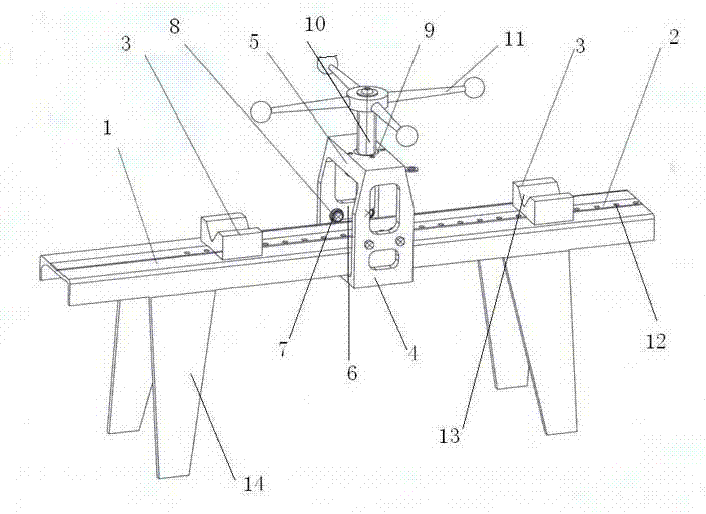

[0014] like figure 1 As shown, a mobile self-pressing type straightening machine includes a frame 1, a guide base plate 2 is provided in the middle of the upper end surface of the frame 1, at least two workpiece placement blocks 3 are provided on the guide base plate 2, and a Removable straightening head4.

[0015] Preferably, the straightening machine head 4 comprises a straightening frame 5, and the inner sides of the two side walls 6 of the straightening frame 5 are respectively provided with a plurality of sliding wheels 7, and each pulley 7 is fixed on the side of the straightening frame 5 by a rotating shaft 8. On the inner sides of the two side walls 6, a nut 9 is provided in the middle of the upper end of the straightening frame 5, and a straightening screw 10 is screwed inside the nut 9, and a handle 11 is provided at the upper end of the straightening screw 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com